Bullet charging and discharging device and quick bullet charging and discharging method thereof

A bomb unloader, fast technology, applied in the direction of grappling hooks, weapon accessories, ammunition supply, etc., can solve the complex processing, assembly and adjustment of the loading and unloading device, and cannot solve the problem of fast loading and unloading of the magazine, Can not be used in all-weather environment and other problems, to achieve the effect of compact and compact overall shape, stable and reliable working state, and convenient unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

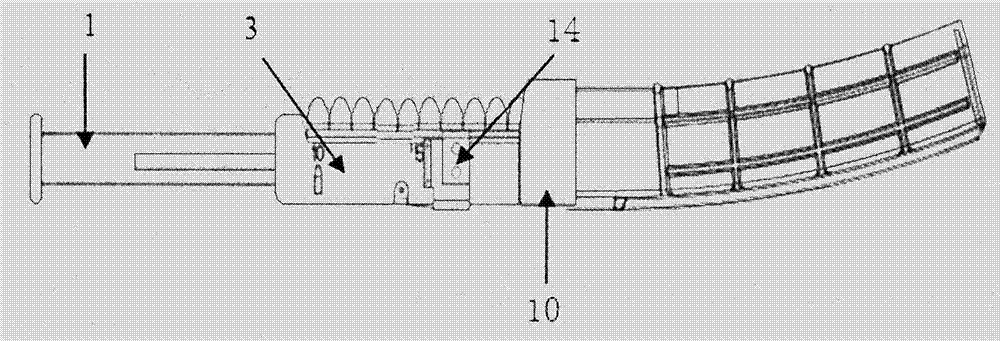

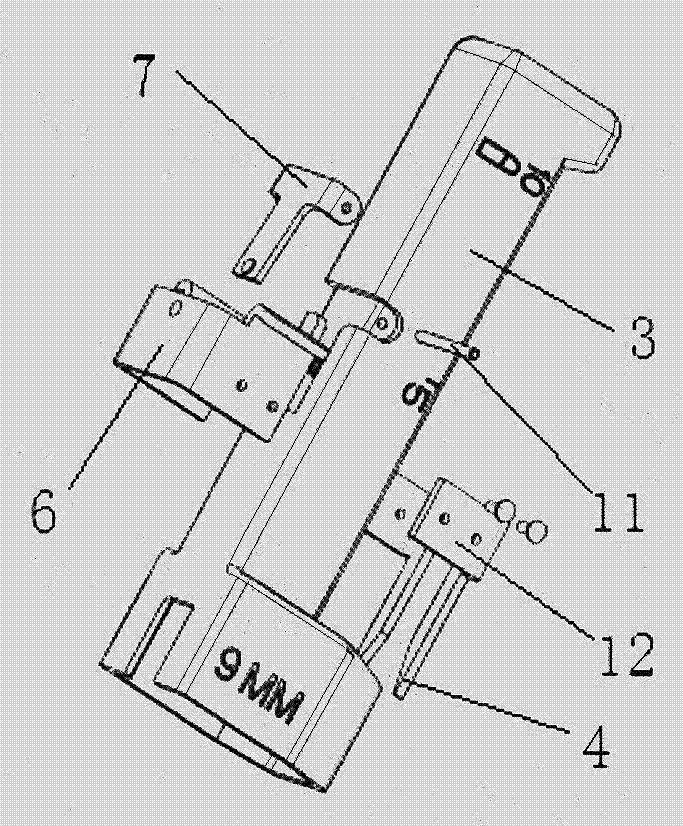

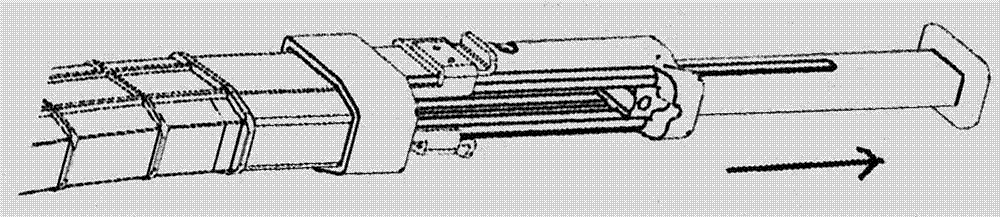

[0025] refer to figure 1 , The loading and unloading device of the present invention includes a bomb holding slot 3, a push bar 1 and a bomb unloading device 14. Among them, refer to Image 6 , The bomb holding slot 3 is provided with a front bag mouth 10 that is movably connected with the magazine. The bullet-holding groove 3 is a rectangular groove, and the two inner walls of the bullet-holding groove 3 are respectively provided with sliding grooves 17 . combined reference Figure 2 to Figure 4 , The push rod 1 is a bar-shaped cube, and its two outer walls are respectively provided with boss keys 9 matched with the sliding groove 17. The rear end of the bomb holding groove 3 is provided with a rear bag opening 19, and the rear bag opening 19 is provided with a limit groove 18, and the front end of the push bar 1 is provided with a limit catch 2, and the limit stop tenon 2 is movably matched with the limit groove 18. Limiting tenon 2 is installed in the limit groove by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com