Cogging method for large GH4738 high-temperature alloy ingot

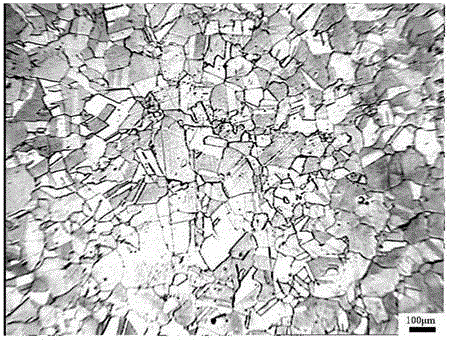

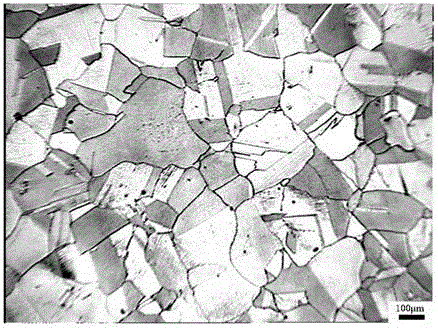

A high-temperature alloy and alloy ingot casting technology, which is applied in the field of GH4738 high-temperature alloy large-scale ingot casting, can solve problems such as instability, uneven structure, mixed crystal performance of grain structure, etc., to improve yield and stability, crystal The particles are uniform and fine, and the effect of satisfying the uniformity of fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

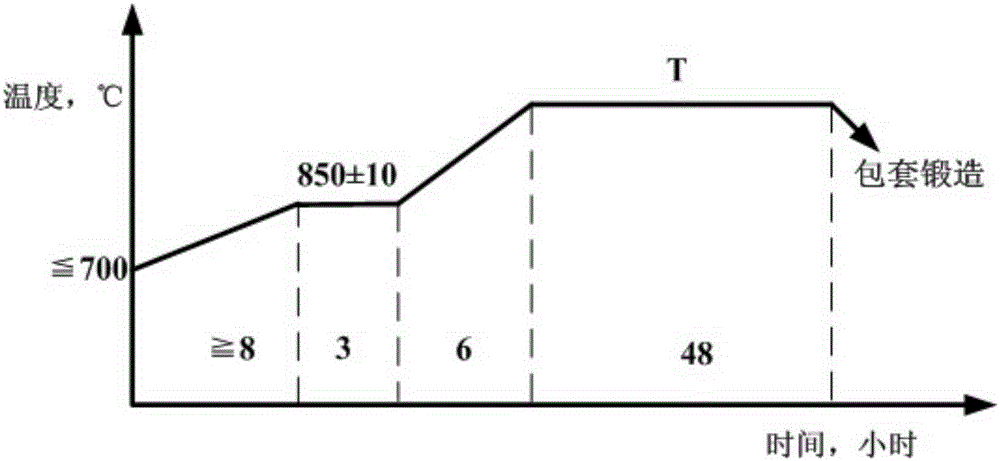

[0024] A kind of GH4738 superalloy large-scale ingot blanking method steps are as follows:

[0025] (1). Put the homogenized large ingot into the heat treatment furnace to heat and keep it warm. The size of the large alloy ingot is Φ510mm;

[0026] (2). Upset the steel ingot heated to the specified temperature to obtain the first cake, and then lengthen the cake to obtain the secondary bar;

[0027] (3). Heating the secondary bar, upsetting to obtain a secondary cake base, and then lengthening the cake base to obtain a third bar, so as to obtain a uniform and fine-grained bar base.

[0028] The specific steps are as follows: heat the large ingot of GH4738 nickel-based superalloy in the heating furnace to 1170°C, and then heat it on the rapid forging hydraulic press for 1s -1 Upsetting the steel ingot to 50% of the height of the original steel ingot to obtain a cake base, and then changing the length of the first cake base back to 80% of the height of the original steel ingot ...

Embodiment 2

[0033] A kind of GH4738 superalloy large-scale ingot blanking method steps are as follows:

[0034] (1). Put the homogenized large ingot into the heat treatment furnace to heat and keep it warm. The size of the large alloy ingot is Φ620mm;

[0035] (2). Upset the steel ingot heated to the specified temperature to obtain the first cake, and then lengthen the cake to obtain the secondary bar;

[0036] (3). Heating the secondary bar, upsetting to obtain a secondary cake base, and then lengthening the cake base to obtain a third bar, so as to obtain a uniform and fine-grained bar base.

[0037] The specific steps are as follows: heat the large ingot of GH4738 nickel-based superalloy in a heating furnace to 1180°C, and then place it on the rapid forging hydraulic press for 1s -1 Upset the steel ingot to 50% of the height of the original steel ingot to obtain a cake base, and then change the length of the first cake base back to 100% of the height of the original steel ingot to obt...

Embodiment 3

[0042] A kind of GH4738 superalloy large-scale ingot blanking method steps are as follows:

[0043] (1). Put the homogenized large ingot into the heat treatment furnace to heat and keep it warm. The size of the alloy ingot is Φ508mm;

[0044] (2). Upset the steel ingot heated to the specified temperature to obtain the first cake, and then lengthen the cake to obtain the secondary bar;

[0045] (3). Heating the secondary bar, upsetting to obtain a secondary cake base, and then lengthening the cake base to obtain a third bar, so as to obtain a uniform and fine-grained bar base.

[0046] The specific steps are as follows: heat the large ingot of GH4738 nickel-based superalloy in the heating furnace to 1170°C, and then heat it on the rapid forging hydraulic press for 1.5s -1 Upsetting the steel ingot to 40% of the height of the original steel ingot to obtain a cake base, and then changing the length of the first cake base back to 80% of the height of the original steel ingot to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com