Method for producing low-carbon steel and ultra-low-carbon steel by VD, LF and VD processes

An ultra-low carbon steel and process technology, which is applied in the improvement of process efficiency and the manufacture of converters, etc., can solve problems such as the decline of enterprise profits and the burden of capital enterprises for equipment renewal, and achieve the effect of saving investment and reducing capital investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

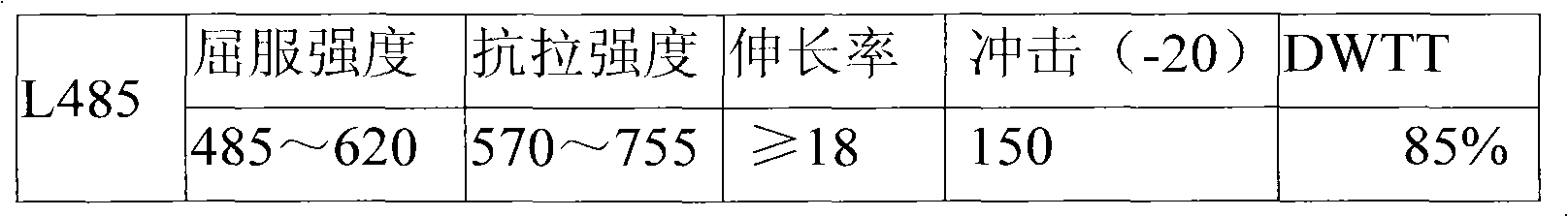

[0018] The specific components are designed as follows:

[0019] C: 0.03~0.09, Si: ≤0.50, Mn: ≤1.80, P: ≤0.020, S: ≤0.010, AlS: 0.015~0.050, Ni+Cr+Mo≤1.0, Nb+V+Ti≤0.15, others are Fe and residual elements; this method is suitable for steel types that require a C content of less than 0.09, and the C content requirement can be achieved through this process. In order to achieve the above purpose, on the basis of the original low-carbon and ultra-low-carbon steel technology, the C content and temperature at the end of the converter are strictly controlled. React with carbon to remove the carbon in the steel to meet the low-carbon requirements, and then go through LF refining treatment to remove sulfur, oxygen and inclusions in the steel, and carry out alloying. After LF treatment, go through a VD vacuum treatment , to remove H, N and other gases in the steel to meet the requirements of clean steel. Combined with the chemical composition of steelmaking, the recrystallization term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com