FDM (frequency-division multiplexing) three-dimensional printing and processing all-in-one machine

A 3D printing and all-in-one machine technology, applied in the direction of additive processing, etc., can solve the problems of increasing the time and cost of printing products, and achieve the effects of reducing capital investment, improving production efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples.

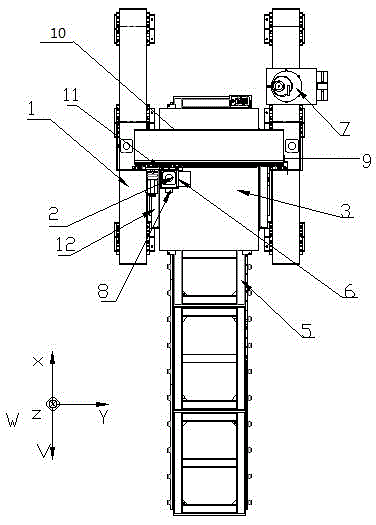

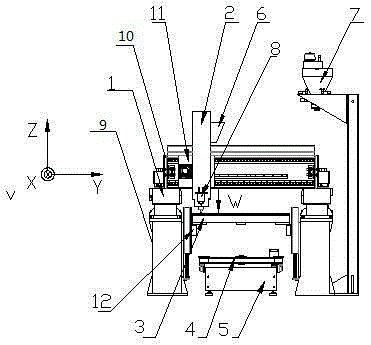

[0028] Attached below Figure 1-2 The present invention is further analyzed.

[0029] as attached figure 1 As shown, the FDM three-dimensional printing and processing integrated machine of the present invention includes a gantry frame 1, an extrusion mechanism 2, a printing platform 3, a transfer trolley 4, a trolley walking track 5, a storage bin 6, a side feeding mechanism 7, and an electric spindle 8 ; The inner circumference of the gantry frame is laid with a walking track, and the inner circumference of the gantry frame is not connected to each other; the moving track is provided with a transfer trolley; the gantry frame includes X / Y axis mobile positioning mechanism and a Z-axis moving and positioning mechanism, the Z-axis moving and positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com