Transfer system and semiconductor manufacturing system

a semiconductor manufacturing and transfer system technology, applied in the field of transfer techniques, can solve the problems of difficult aggregate capital investment of the entire factory, and achieve the effect of improving the transfer ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0025] First Embodiment

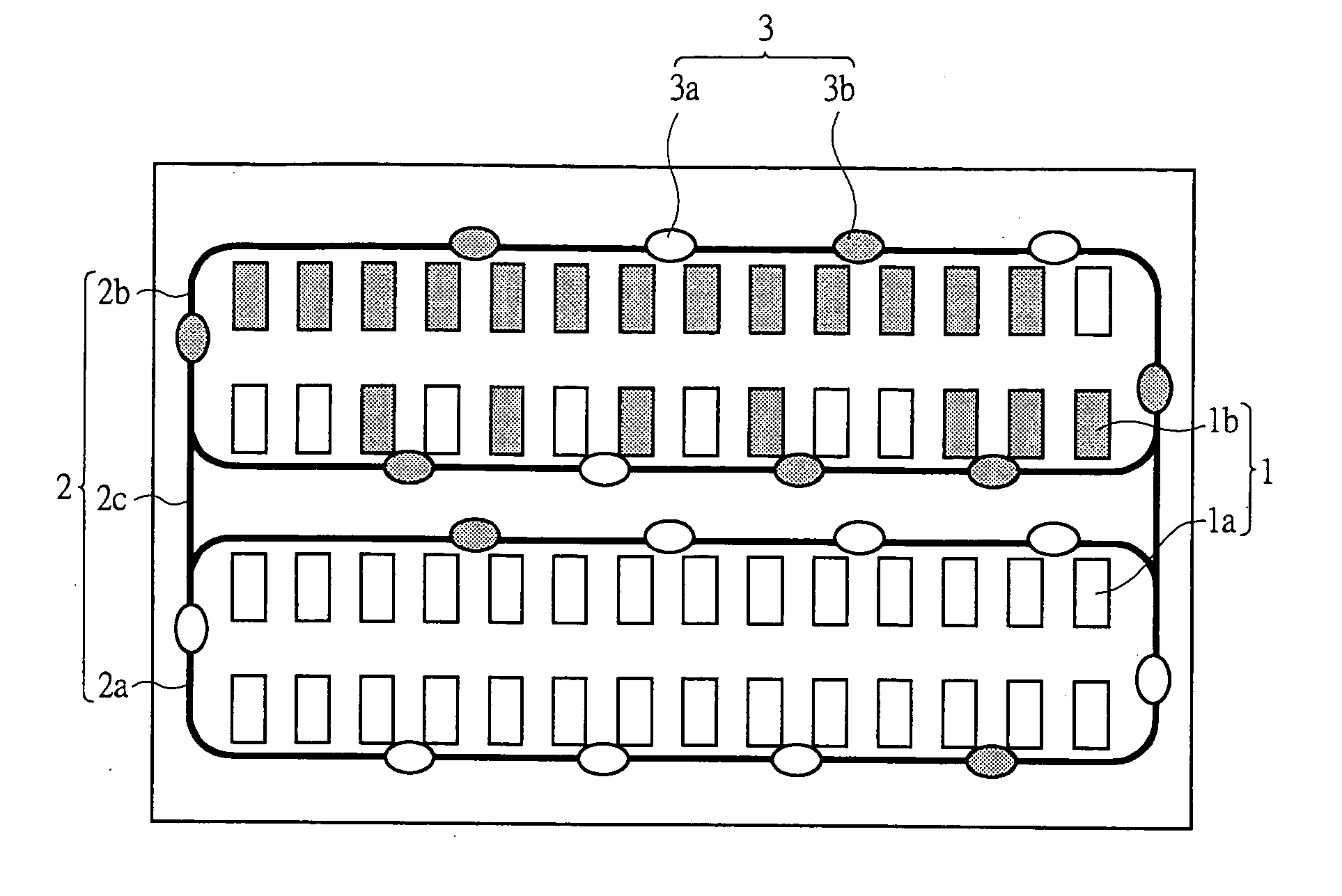

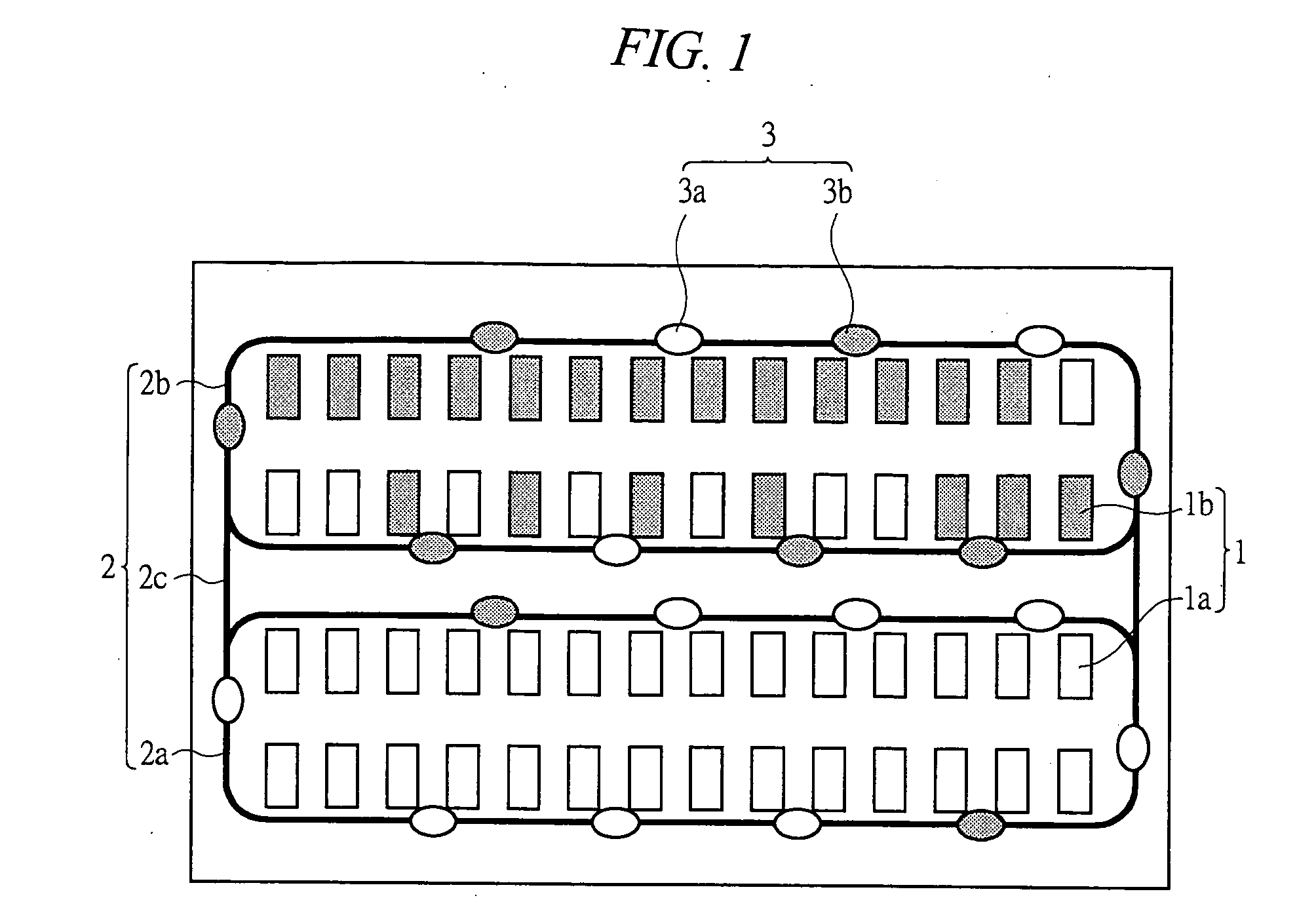

[0026] In the first embodiment, a transfer system that covers the entire space of a factory is established when constructing the factory. The number of equipments to be provided in the initial stage of constructing the factory is not so large that the entire space of the factory cannot be filled, and additional equipments will be provided when it is necessary to reinforce the ability of the factory.

[0027] More specifically, in the initial stage of constructing the factory, the number of carriers is so limited as to meet the transfer requirement. When the ability of the factory is required to be reinforced in the future, additional equipments will be provided, and simultaneously, additional carriers will also be provided. Additional carriers to be provided have to run on existing tracks and are upgraded type whose running speed is higher than that of the initially provided carriers.

[0028] As a result, new carriers and old carriers whose running performances a...

second embodiment

[0053] Second Embodiment

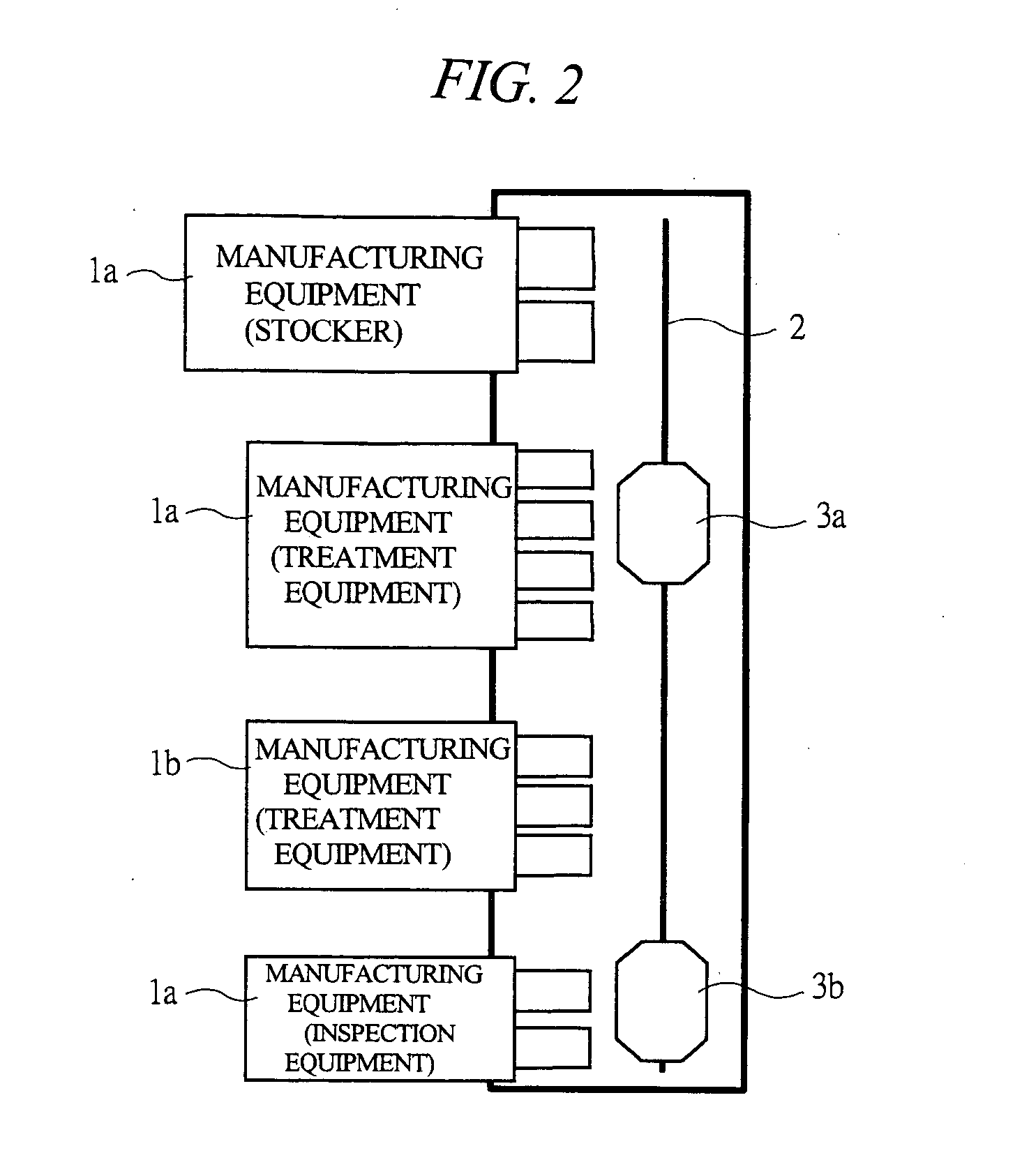

[0054] In the second embodiment, a transfer system is constructed and operated at a part of the factory space. More specifically, in order to reinforce the ability of the factory, the transfer system is expanded to the space where there exists no equipment, and the existing tracks are extended to realize the transfer to the expanded area. At this time, the number of carriers needs to be increased with the expansion of the transfer area as well as the improvement of the transfer ability. In this case, carriers that can run at high speed are additionally provided.

[0055] As a result, similar to the first embodiment, new carriers and old carriers each having different running performances are simultaneously provided on the same tracks, and therefore, the average transfer time of the entire factory can be reduced in comparison to the case where the carriers having the same running performance as that of the initially provided carriers are additionally provided.

[...

third embodiment

[0059] Third Embodiment

[0060] In the third embodiment, a new factory is constructed next to an existing factory that employs a transfer system. Since the objects are frequently transferred between the existing factory and the new factory, it is necessary to minimize the transfer time in the existing and new factories and that between the existing factory and the new factory. Thus, the carriers running in the existing factory and the carriers running in the new factory have to mutually move to the other factories. In the new factory, the carriers running at high speed are provided.

[0061] As a result, similar to the first embodiment, new carriers and old carriers each having different running performances are simultaneously provided on the same tracks, and therefore, the transfer time in the new factory can be significantly reduced and also the average transfer time of the entire factories including the inter-factory transfer time can be reduced in comparison to the case where the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com