Fatigue test device for vehicle body thin plate, and test method thereof

A fatigue test and fatigue test technology, applied in the direction of applying repetitive force/pulsation force to test the strength of materials, etc., can solve the problem of large force on the edge part, affecting the force state of the lateral edge part of the sample, and lack of plastic thin plate material conditional fatigue limit and other issues to achieve the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

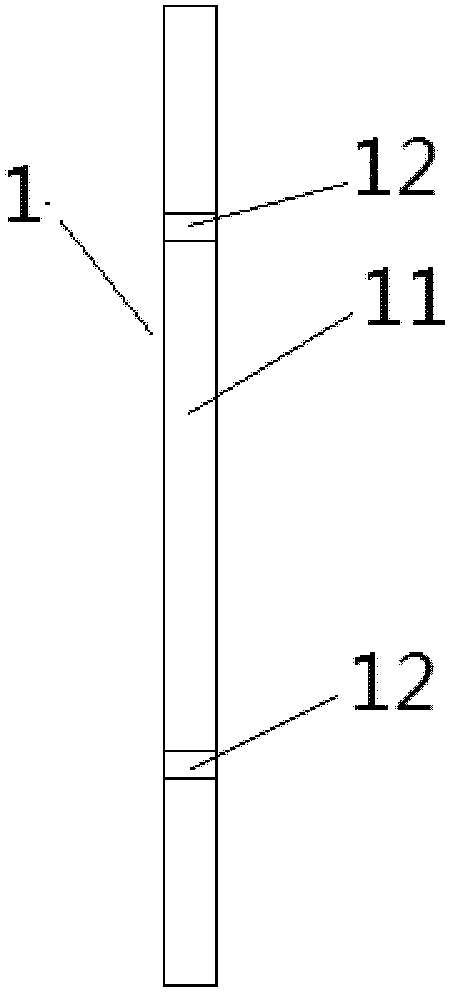

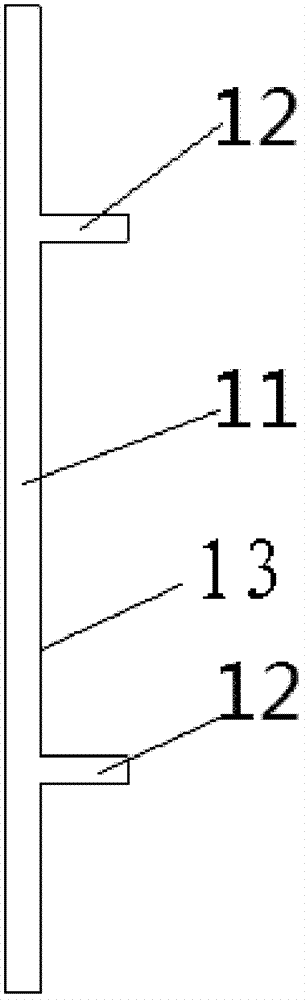

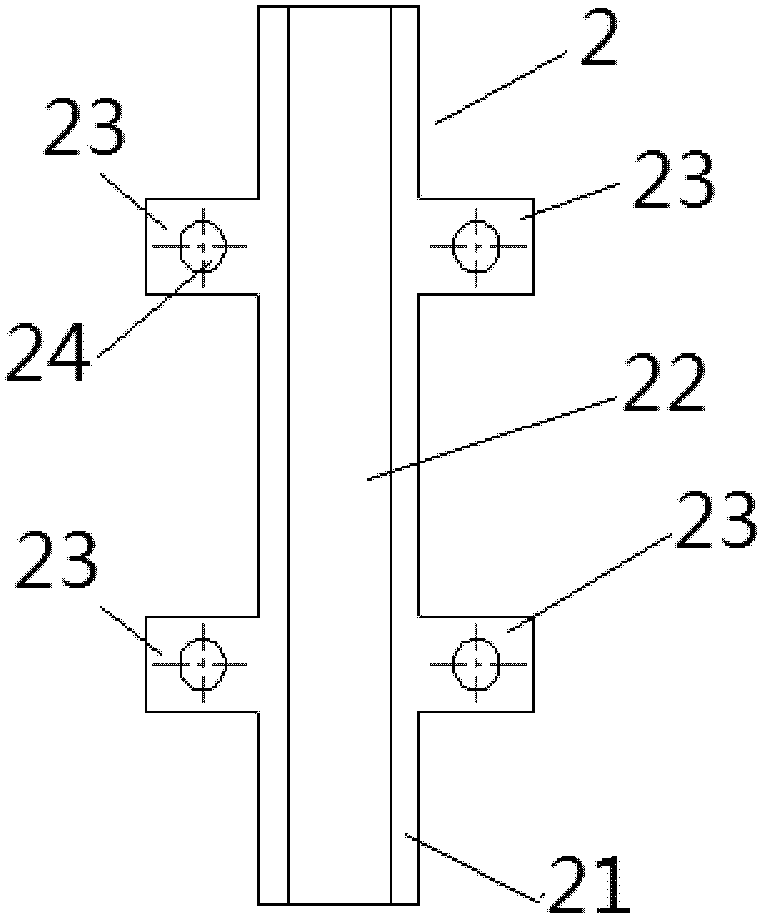

[0044] The body sheet fatigue test device provided by the present invention is mainly composed of the following parts: a fixture 4 , a centering device 1 and an anti-bending restraint device 2 . The clamp 4 is used to clamp the two ends of the fatigue sample 3, and the centering device 1 is as figure 1 and figure 2 As shown, it is used to install the fatigue sample 3 during the tension and tension-compression fatigue test, make it centered, and ensure the consistency of the installation of the same batch of fatigue samples 3. Centering device 1 includes:

[0045] The column 11 is provided with a reference plane 13 corresponding to the two clamps 4 clamped on the fatigue sample 3, and is used to keep the two clamps 4 on the same refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com