Method for fatigue analysing and testing by refrared thermal imagery

A technology of fatigue analysis and infrared thermal imaging, which is applied in the direction of material analysis, material analysis, and application of stable tension/pressure to test the strength of materials through optical means, and can solve problems such as temperature changes that do not consider non-fatigue effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below:

[0021] Fatigue of materials is a process of energy dissipation. Temperature change is an important parameter to study the fatigue process. It can not only determine the location of fatigue damage, but also monitor its evolution intuitively. The amount of heat dissipation not only reflects the difference in the different damage processes of the material, but also reflects the irreversible characteristics of the material damage process.

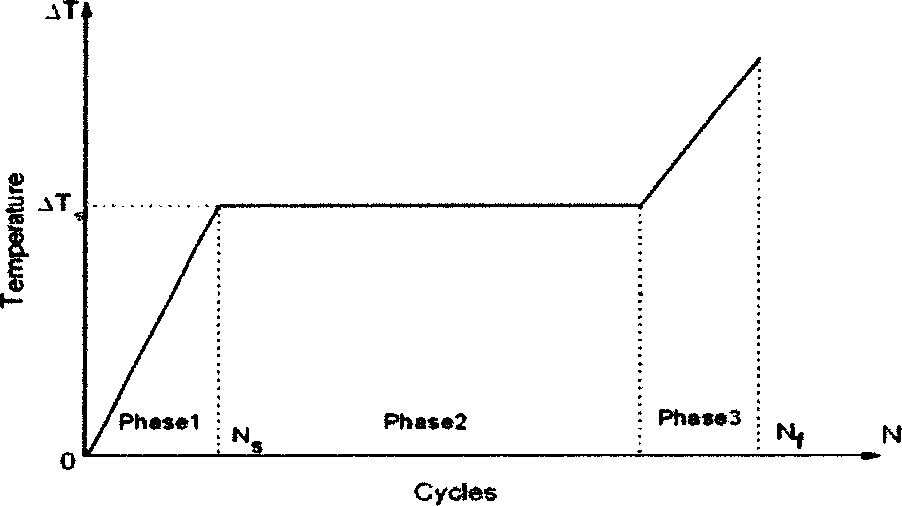

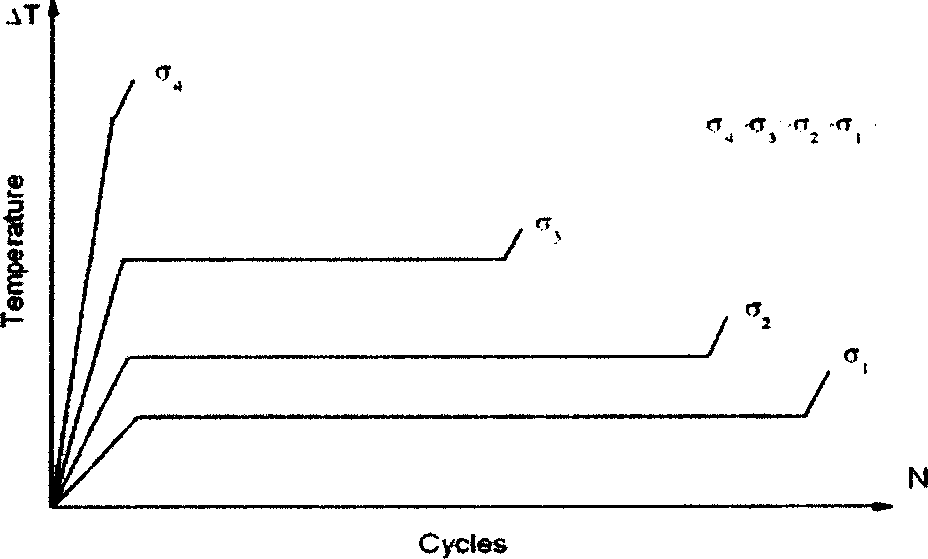

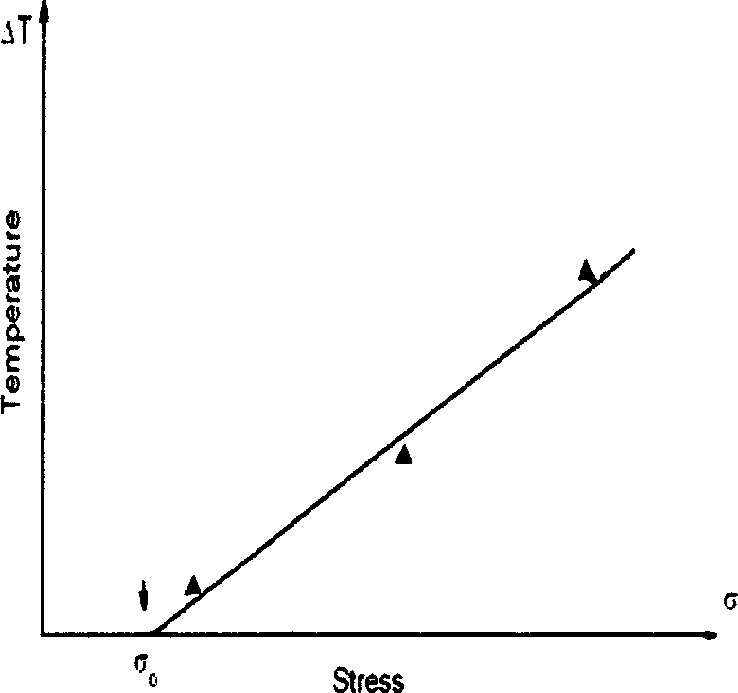

[0022] The researchers concluded from a large number of experiments that the temperature change in the process of material fatigue can be divided into three distinct stages as follows: figure 1 As shown, ΔT is the maximum surface temperature T and room temperature T of the specimen under the action of cyclic load during the experiment 0 Difference. Experiments have found that under the condition of a certain load frequency, when the load exceeds the fatigue limit σ of the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com