Structure fatigue life calculation method based on non-linear cumulative damage theory

A technology of cumulative damage and fatigue life, applied in the testing, measuring devices, instruments, etc. of machine/structural components, which can solve problems such as poor engineering applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below in conjunction with the drawings and embodiments.

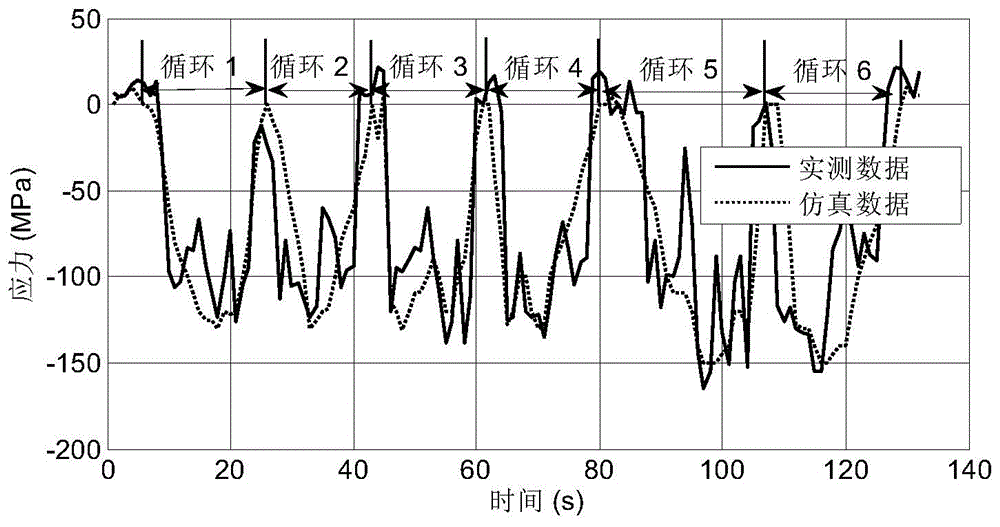

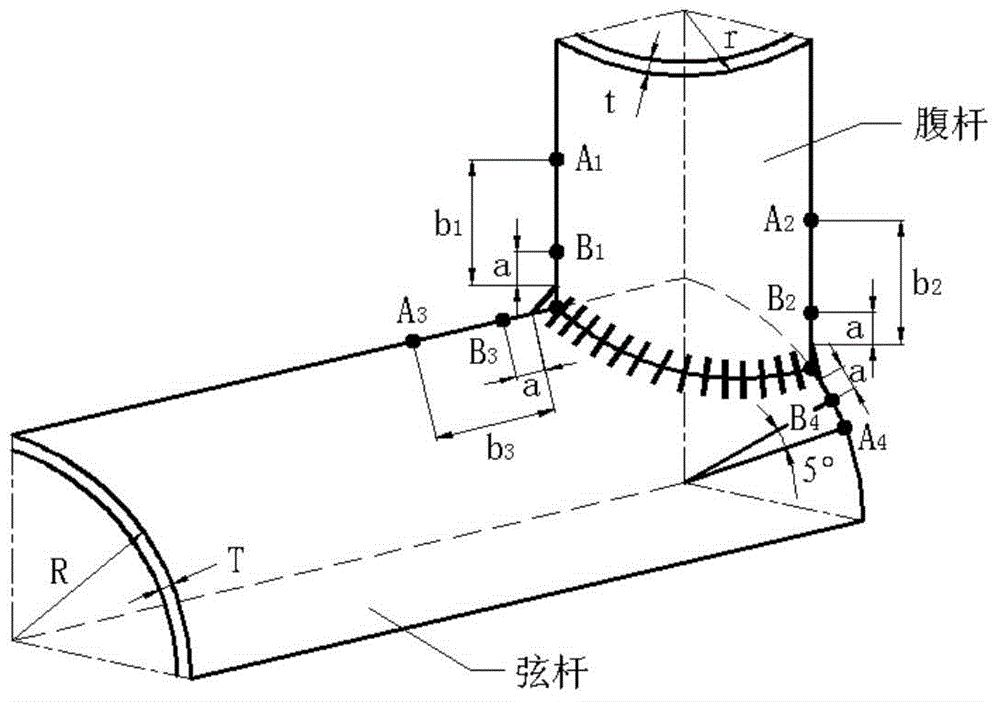

[0058] Case selected Figure 5 The welded structure shown is taken from a dangerous section of the truss boom of a rubber-tyred crane. The material parameters are: when the material is Q345B, the elastic modulus E = 200741MPa, the fatigue strength index b = -0.0943, the fatigue ductility index c = -0.5395, the fatigue strength coefficient σ f '=947.1MPa, fatigue ductility coefficient ε f '=0.4644, with cycle hardening characteristics.

[0059] Determine its fatigue life by calculating its complete cumulative damage. Specific steps are as follows:

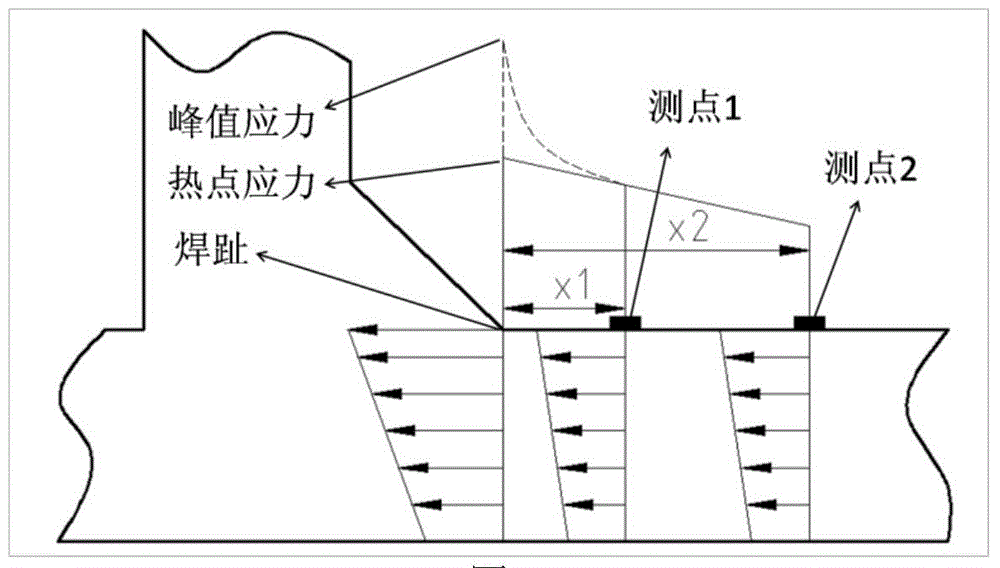

[0060] Step 1: Determine the fatigue risk area of the component through the finite element analysis software. By right Figure 5 Establish a finite element model, analyze two typical working conditions in Ansys, and obtain multiple points with larger stress values. Two typical working conditions are shown in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com