Method for predicting multiaxial fatigue of automobile rear suspension

A rear suspension and automobile technology, which is applied in the direction of measuring devices, vehicle testing, mechanical parts testing, etc., can solve problems such as inability to count cycles, fatigue damage, etc., and achieve the effect of improving calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Please refer to the attached drawings to further describe the present invention.

[0024] The following briefly explains the principle:

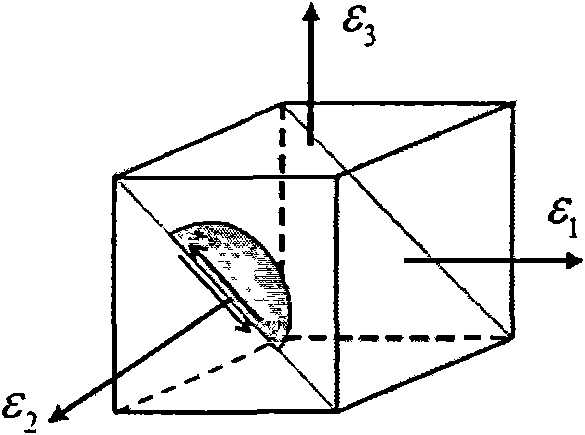

[0025] 1. Theory of elastoplastic deformation

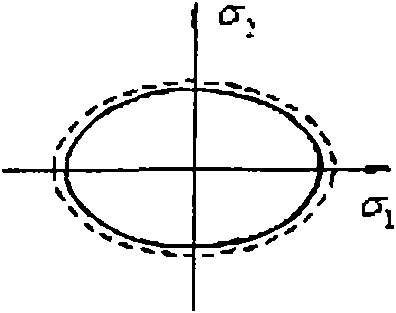

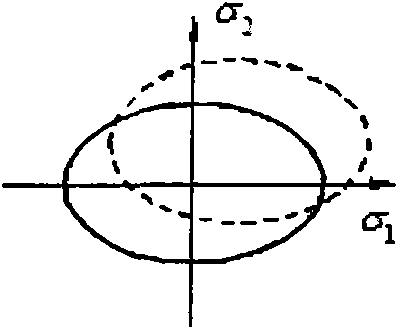

[0026] 1) Yield criterion

[0027] The yield criterion is used to determine the magnitude of the stress at the beginning of plastic deformation. The common yield criteria are the Von Mises criterion and the Tresca criterion. For most metals, the Von Mises criterion is more consistent with the experimental data than the Tresca criterion.

[0028] The Von Mises criterion believes that for isotropic materials, when J 2 The material yields when reaching a certain value, that is

[0029] J 2 =K (1)

[0030] Among them, K is the material parameter to be determined. The test proves that K is equal to the uniaxial test yield stress σ s One-third of the square, i.e. K = 1 3 σ s 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com