Method for predicting fatigue life of multi-nail connecting pieces under spectrum loading

A technology for fatigue life and connectors, which is applied in the field of predicting the spectrum load fatigue life of multi-nail connectors, and can solve the problems of low calculation accuracy and efficiency, many influencing factors, and inconvenient design and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Figure 7 It is the block flow chart of method for the present invention, and the present invention is realized in five steps, specifically:

[0076] Step 1. Fatigue S-N curve of a small sample of a simple single-nail connector

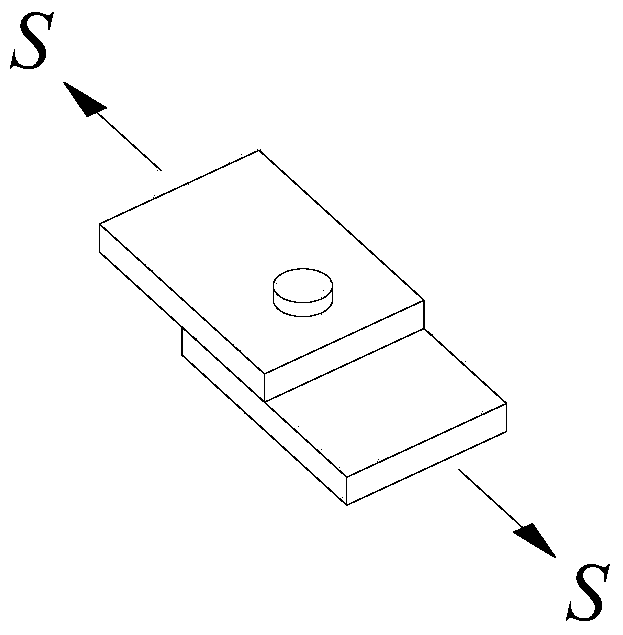

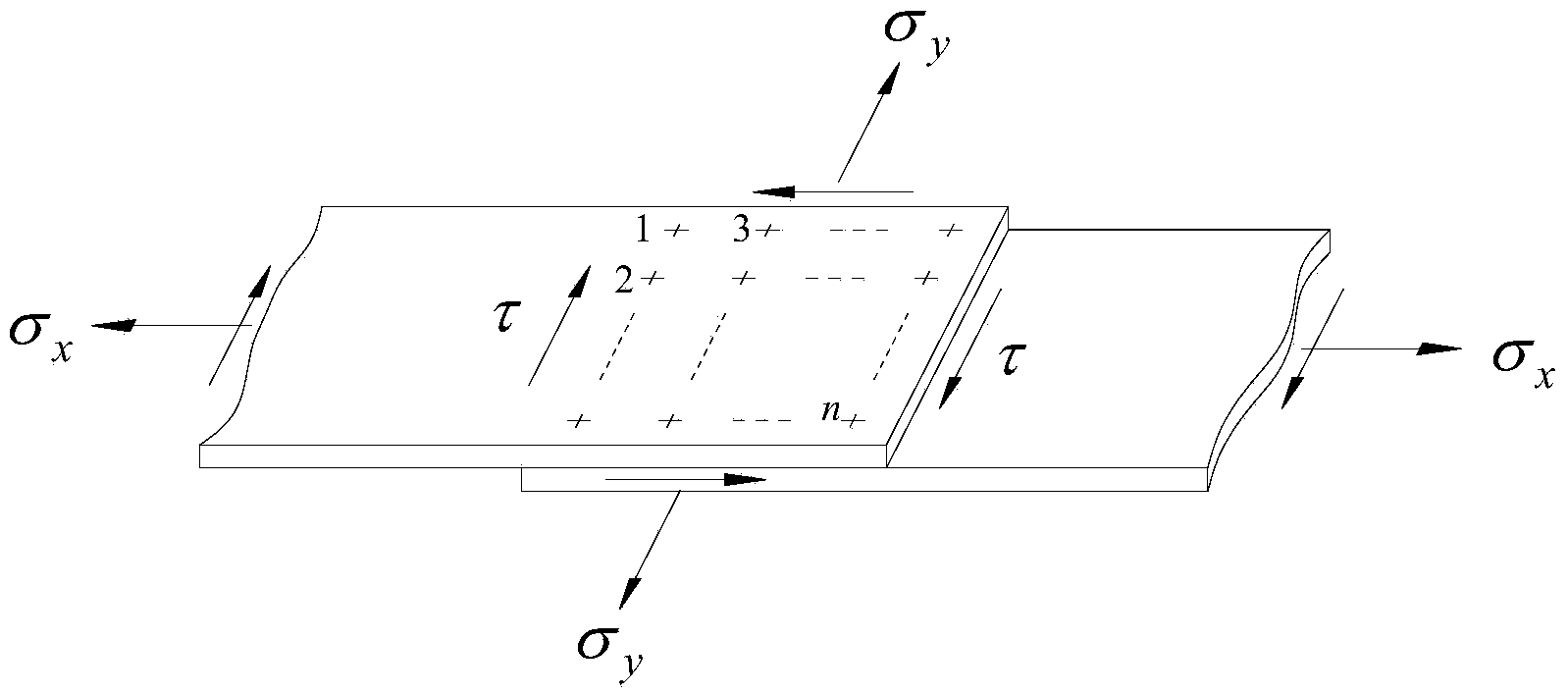

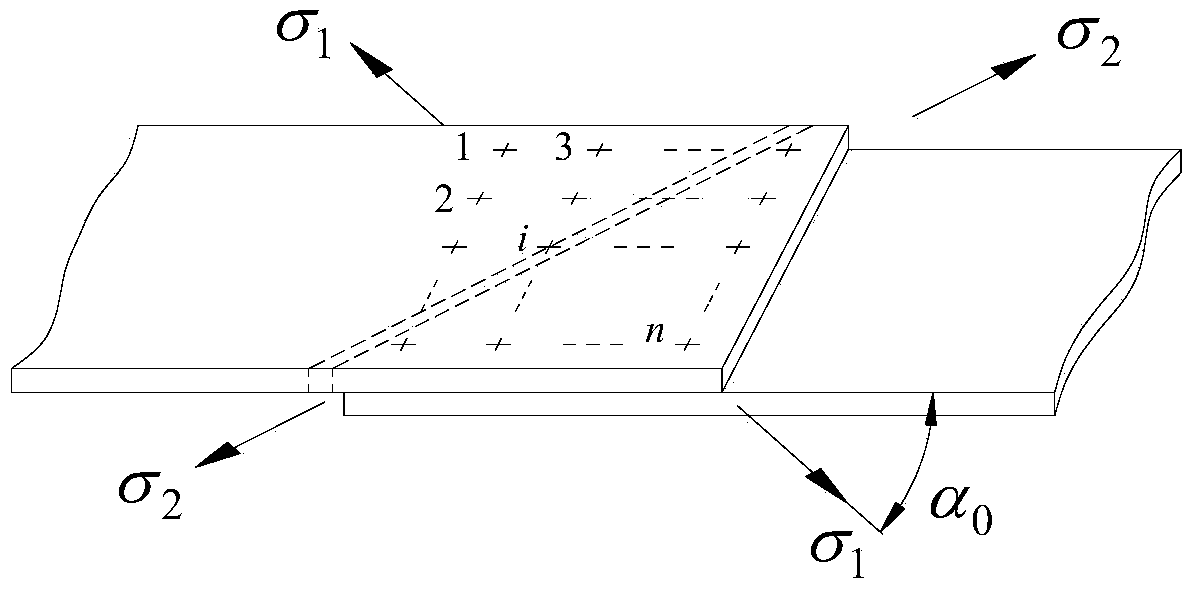

[0077] figure 1 is a schematic diagram of the loading of a single-nail connector, according to figure 1 The load loading form and the national standard "Metal Axial Fatigue Test Method" (GB3075-82), through the fatigue test, determine the specified stress ratio R 0 The following is the fatigue S-N curve of a small sample of a simple single-nail connector:

[0078]

[0079] In the formula, S max and S min are the maximum and minimum values of fatigue test cycle stress respectively; S 0 is the fatigue limit of the single-nail connector, which is determined by the test; N is the fatigue life of the single-nail connector; m and C are the shape parameters of the curve equation, and the test data is in accordance with the "Statistical Anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com