BGA (Ball Grid Array) welding spot structure parameter optimization method for reducing power cyclic stress

A technology of power circulation and structural parameters, applied in design optimization/simulation, complex mathematical operations, electrical digital data processing, etc., can solve reliability problems and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] A method for optimizing the structural parameters of BGA solder joints for reducing power cycle stress, specifically comprising the following steps:

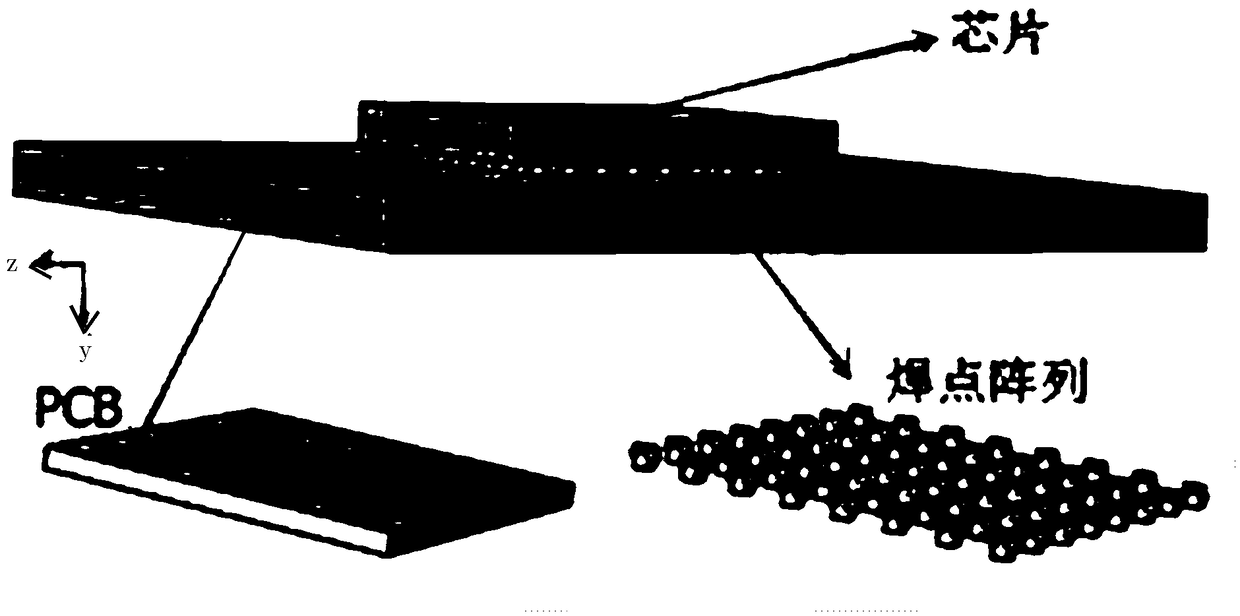

[0060] (1) Establish COMSOL solder joint simulation analysis model, the model is as follows figure 1 As shown, the material parameters are shown in Table 1;

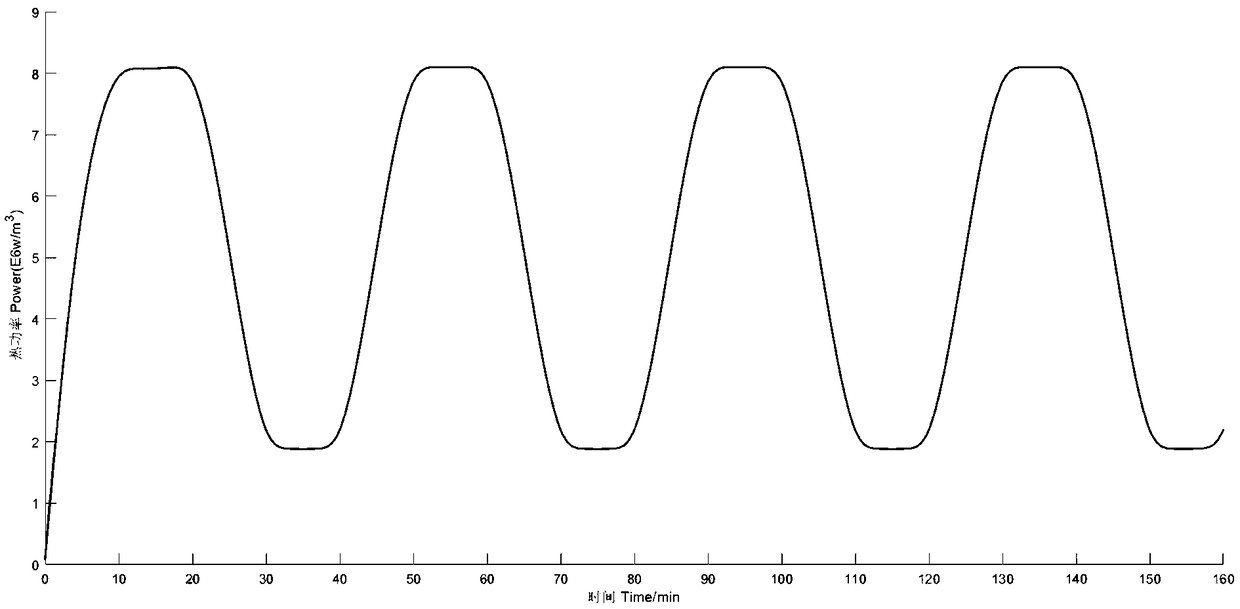

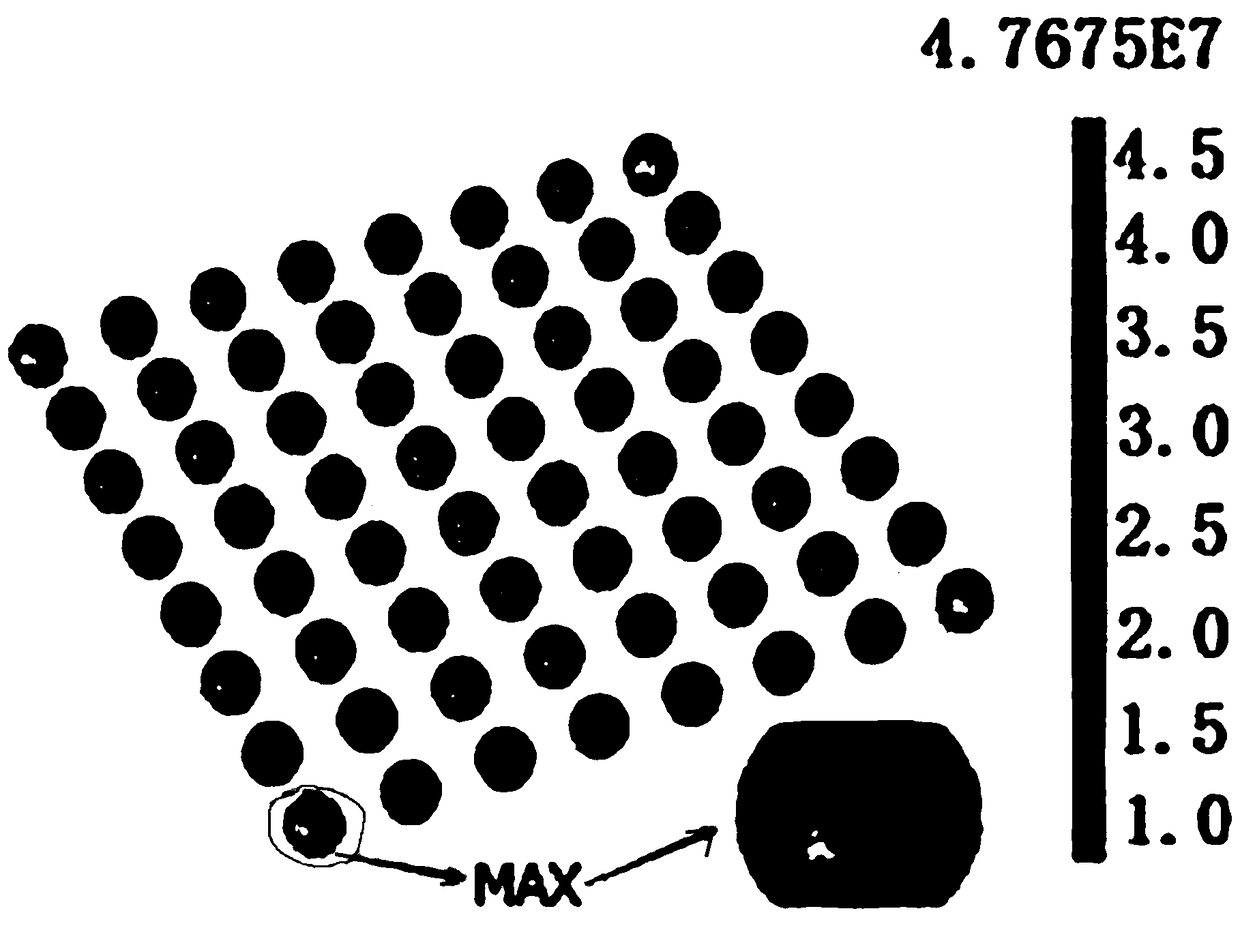

[0061] (2) Obtain the stress value under the power load, and apply the power load curve as figure 2 As shown, the stress diagram obtained by simulation is as follows image 3 shown;

[0062] (3) Obtain the influencing factors that affect the solder joints: the maximum radial size of the solder joints, the height of the solder joints, and the diameter of the upper and lower pads; select 3 levels for each factor, and the factor levels are shown in Table 2;

[0063] (4) Using the BOX-Behnken central combination design model, there are 29 groups of simulation model level combinations, of which 24 groups are analysis factors, and 5 groups are zero-point factors, that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com