Carbon composite material, preparation method for carbon composite material and battery

A technology of carbon composite materials and silicon-based materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A method for preparing a carbon composite material, comprising the steps of:

[0043] S1. Coating a silicon-based material or a tin-based material on graphite particles to obtain a first core-shell material;

[0044] S2. Uniformly disperse the first core-shell material and the carbon precursor in the dispersant, and react at a temperature of 160-180° C. and a pressure of 0.15-0.3 MPa for 3-6 hours to obtain a carbon composite material.

[0045] In S1, the coating can choose chemical coating or physical coating according to the actual situation. Among them, chemical coating can adopt vapor phase deposition method, such as SiO 2 As the raw material, a low-vacuum tube furnace system is used, and Ar gas or N 2 Gas is used as the carrier gas, the reaction pressure is adjusted to 50000Pa, the temperature is 900-1200°C, and the reaction is carried out for 1-3h. Wherein, the physical coating may be ball mill coating or stirring coating, for example, the nano silicon fiber an...

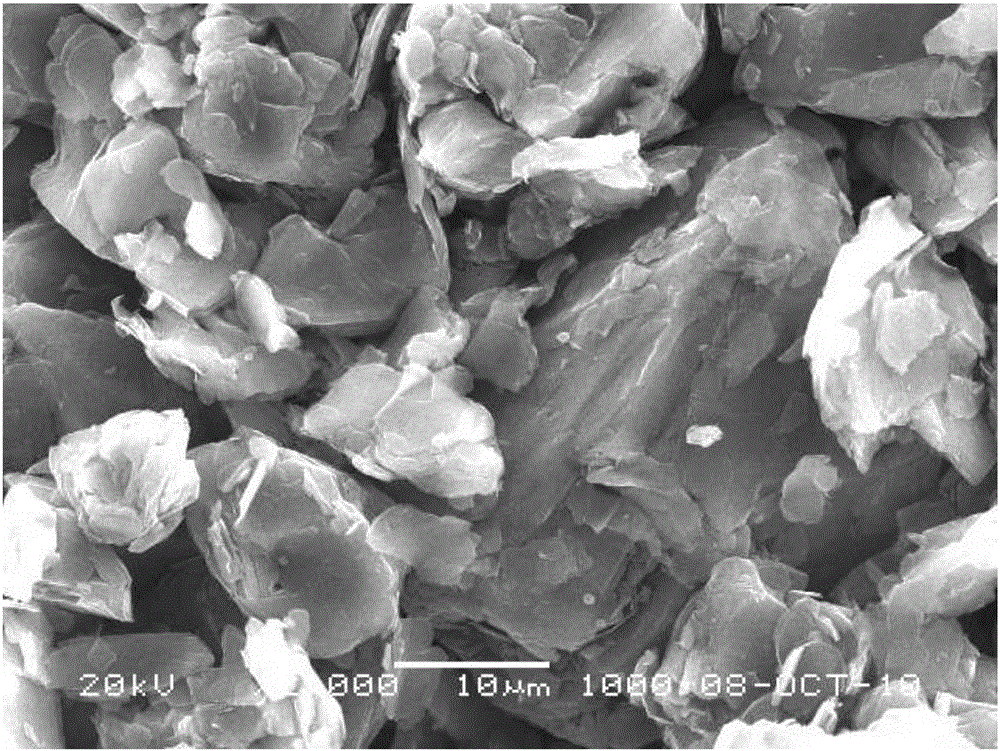

Embodiment 1

[0055] 30g of natural graphite (average particle size: 25μm) was placed in a ball mill, and then 3g of nano silicon fibers (diameter less than 100nm, length 1μm-50μm) were added to obtain the first core-shell material.

[0056] The obtained first core-shell material was placed in a 1L tempered reaction kettle, and then 200g of cellulose aqueous solution (1wt%) was added; the reaction was carried out at 170°C and 0.25MPa for 6h.

[0057] The obtained carbon composite material is denoted as A1.

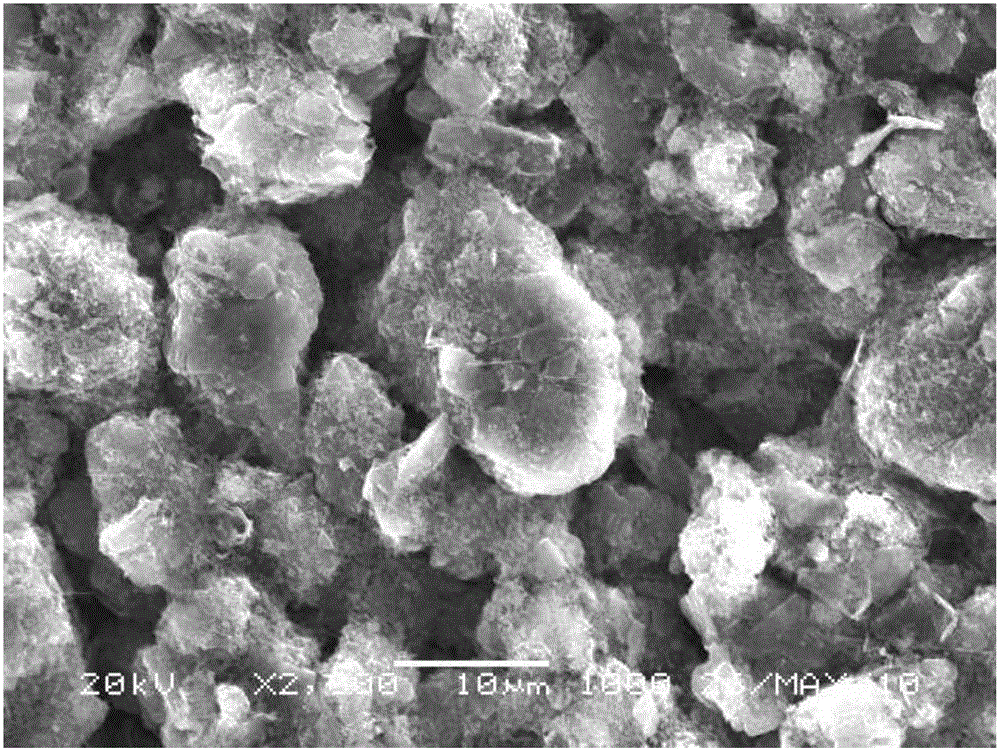

Embodiment 2

[0059] In a low-vacuum tube furnace system, 6 g of SiO 2 As a raw material, use Ar gas as a carrier gas, react at a pressure of 50,000 Pa and a temperature of 1,000°C for 2 hours, and wait for the first core-shell material.

[0060] The obtained first core-shell material was placed in a 1L tempered reaction kettle, and then 300g of sucrose aqueous solution (1wt%) was added; the reaction was carried out at 180°C and 0.15MPa for 5h.

[0061] The obtained carbon composite material is denoted as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com