Method for refining crystalline grains of wrought magnesium alloy at room temperature

A deformed magnesium alloy, room temperature technology, applied in the field of magnesium alloy materials, can solve problems such as not suitable for commercial production, achieve easy yield, and expand the use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The method for refining the deformed magnesium-zinc-manganese alloy at room temperature in this embodiment includes the following steps:

[0031] 1) The magnesium alloy ingot is extruded and deformed at 350℃, the extrusion ratio is 16, and the extrusion speed is 50mm / min;

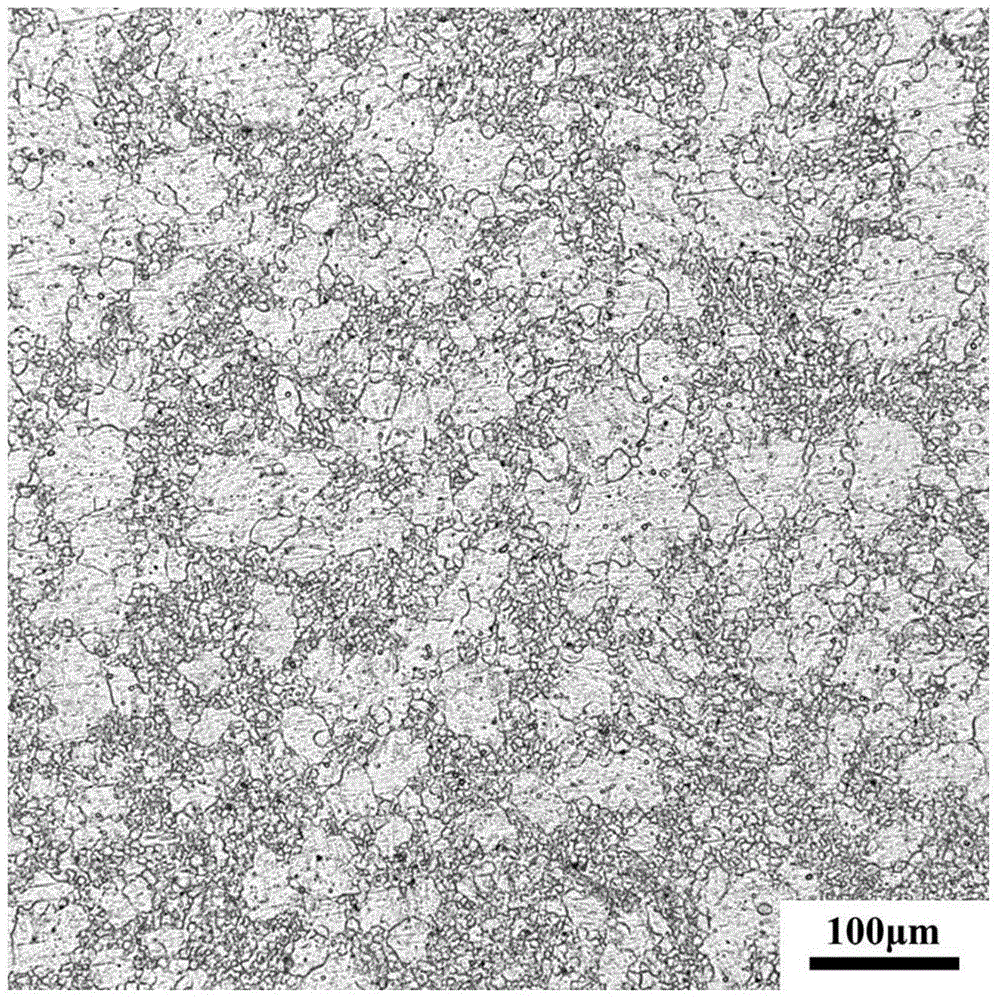

[0032] 2) Process the wrought magnesium alloy bar prepared in step 1 into a funnel-shaped sample. The surface of the sample is smoothed with sandpaper, and the roughness is between 0.32. The microstructure diagram of the magnesium-zinc-manganese alloy bar is as follows figure 1 Shown

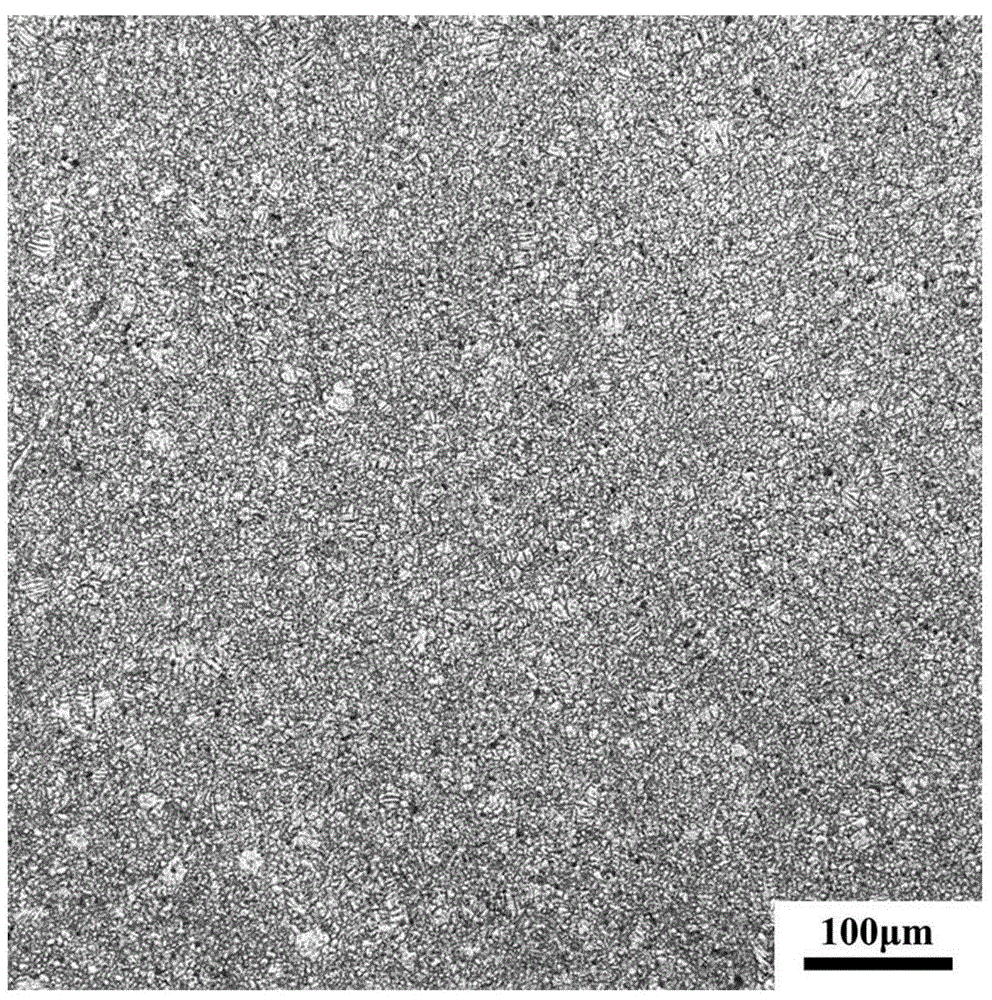

[0033] 3). Clamp the sample prepared in step 2 on the fatigue testing machine for tension-compression cyclic loading, the loading frequency is 40Hz, the loading method adopts stress control, the loading stress is 123Mpa (65% yield strength), and the cycle loading cycle is 2.4× 10 6 Times, figure 2 This is the microstructure diagram of the magnesium alloy obtained in Example 1.

Embodiment 2

[0035] The method for refining the deformed magnesium-zinc-manganese alloy at room temperature in this embodiment includes the following steps:

[0036] 1) The magnesium alloy ingot is extruded and deformed at 350℃, the extrusion ratio is 16, and the extrusion speed is 50mm / min;

[0037] 2) Process the wrought magnesium alloy bar prepared in step 1 into a funnel-shaped sample, and the surface of the sample is smoothed with sandpaper, and the roughness is between 0.32;

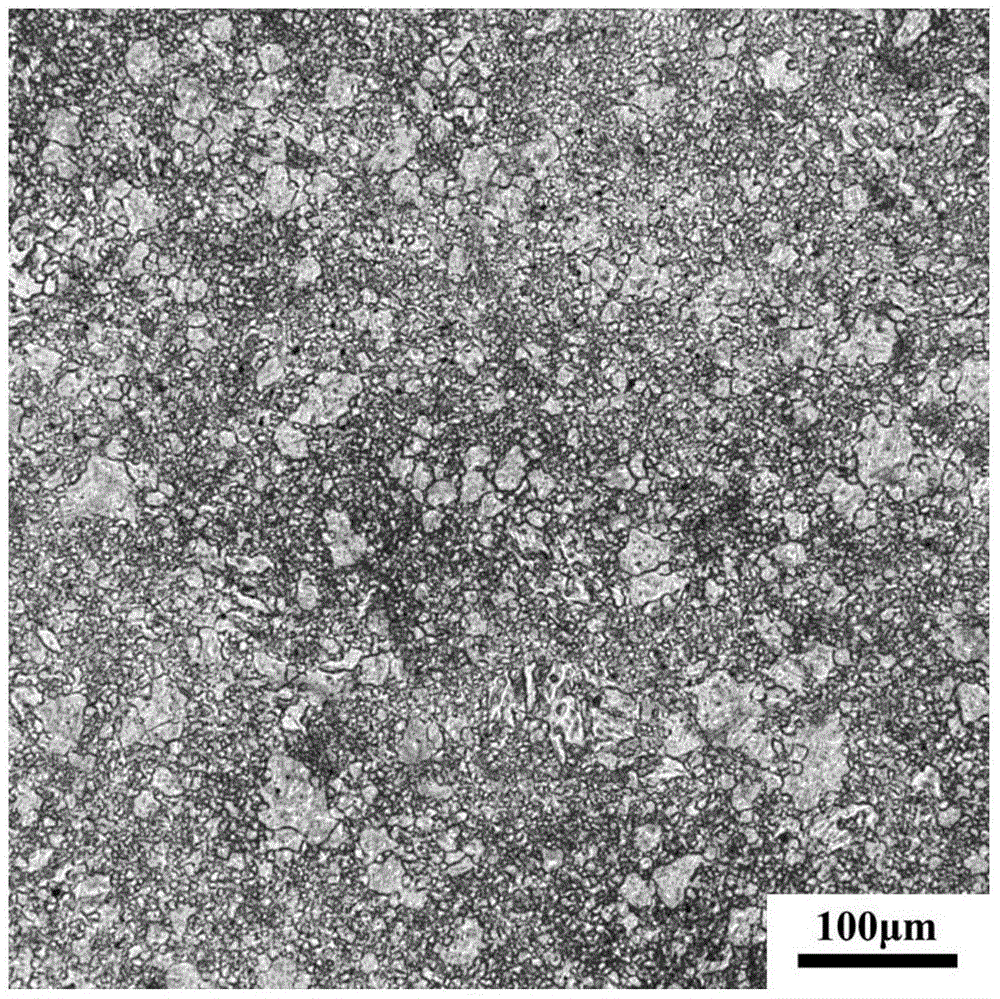

[0038] 3). Clamp the specimen prepared in step 2 on the fatigue testing machine for tensile-pulling cyclic loading, the loading frequency is 40Hz, the loading method adopts stress control, the loading stress is 160Mpa (85% yield strength), and the cycle loading cycle is 2.3× 10 6 Times, image 3 This is the microstructure diagram of the magnesium alloy obtained in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com