Five-axis shot blasting equipment

A shot peening and equipment technology, used in metal processing equipment, abrasive jet machine tools, used abrasive processing devices, etc. Alternate shot peening of components, etc., to achieve the effect of convenient installation, reliable connection, and avoiding cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

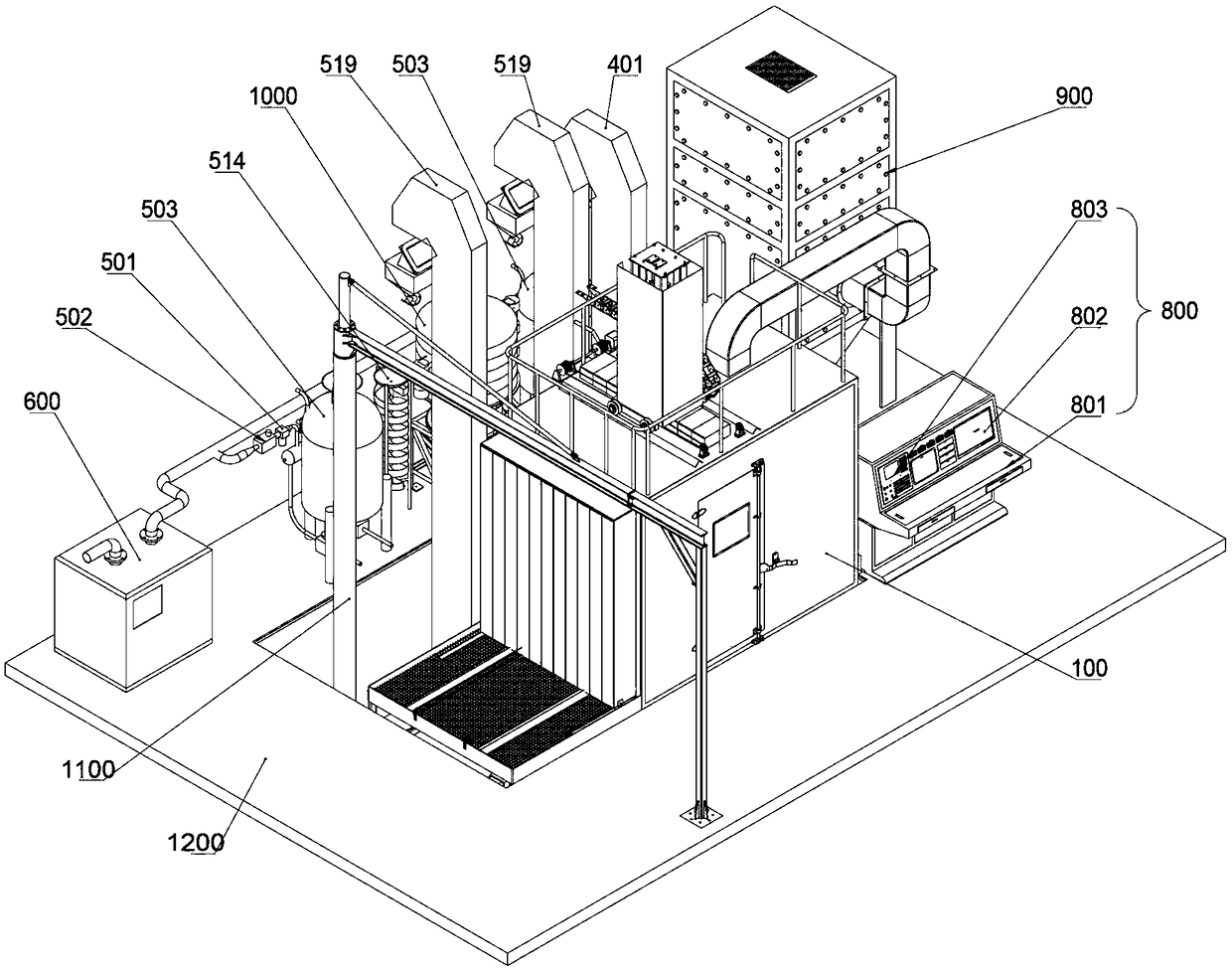

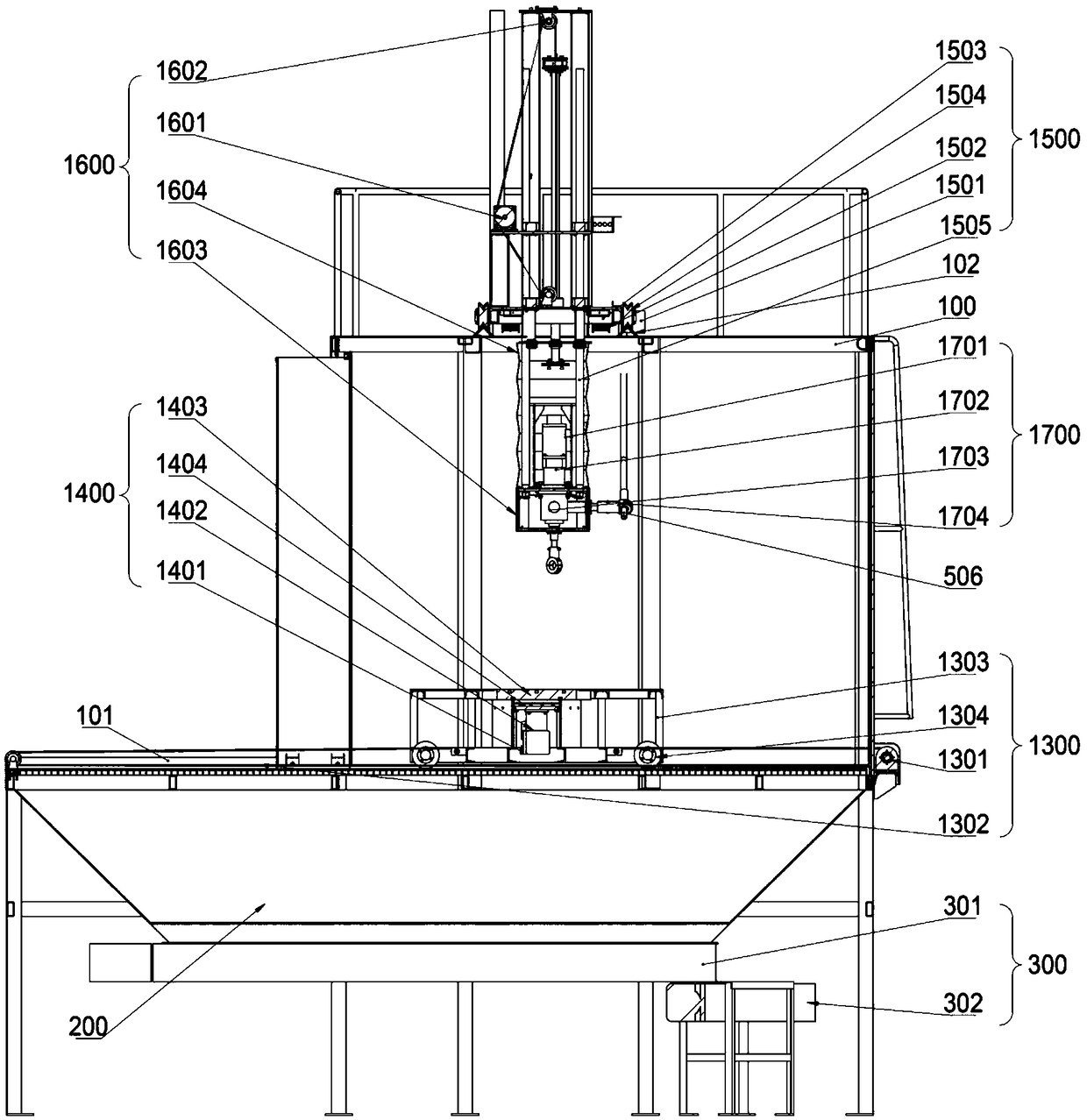

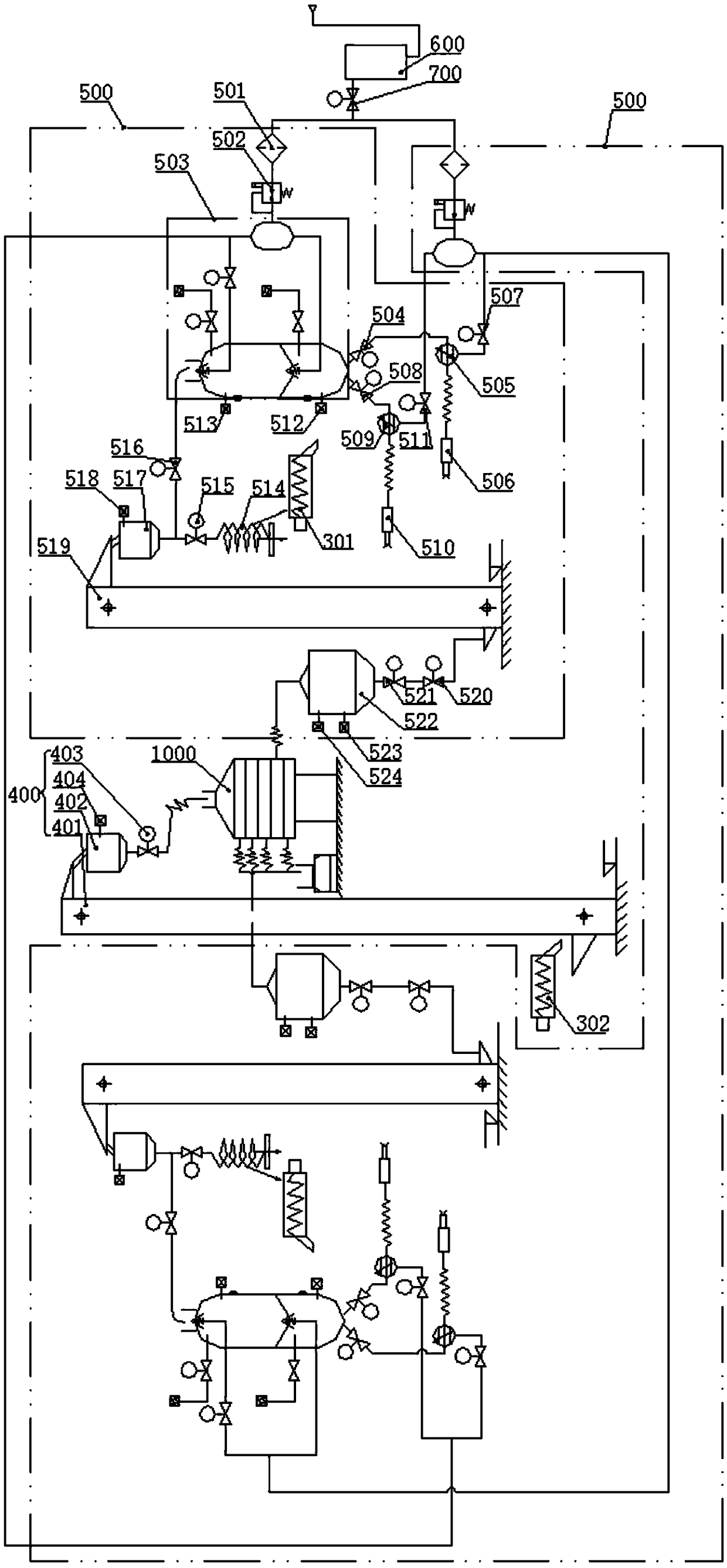

[0058] see Figure 1 to Figure 3 , a five-axis shot peening device of the present invention, comprising a shot peening studio 100, a product moving platform 1300 in the X-axis direction, a product rotating platform 1400 in the A-axis direction, a nozzle moving platform 1500 in the Y-axis direction, a nozzle moving platform 1600 in the Z-axis direction, and a B Shaft nozzle rotating platform 1700 , shot collection bin 200 , shot delivery system 300 , shot lifting system 400 , shot separation device 1000 , positive pressure shot peening system 500 , air source treatment system 600 and control device 800 .

[0059] see figure 1 and figure 2 , in the present embodiment, shot peening working room 100 comprises the steel structure room of surrounding closure, and the steel structure room is provided with push-pull type product warehouse door and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com