Plate multipoint divisional forming method and divisional pressing type multipoint forming device

A multi-point forming and plate forming technology, which is applied in the field of mechanical engineering, can solve problems such as wrinkling of workpieces, and achieve the effects of preventing wrinkling and springback, saving trimming processes, and saving edge-holding devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

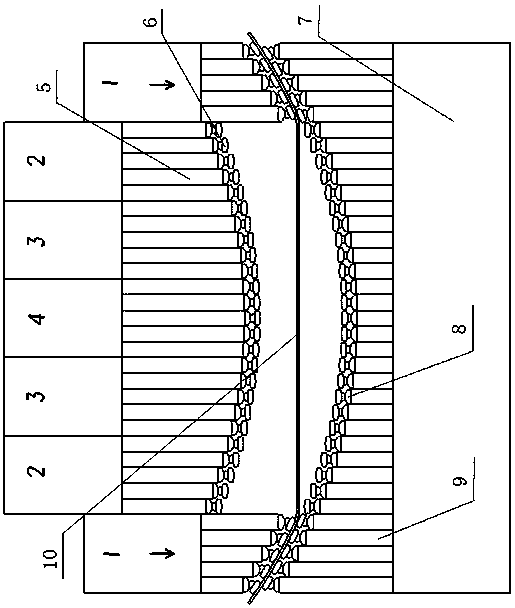

[0023] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

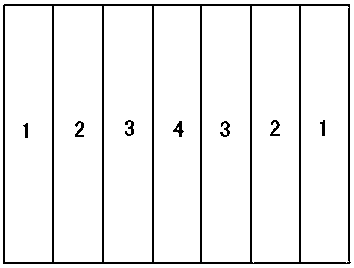

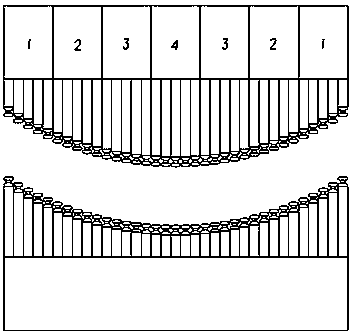

[0024] The multi-point forming device of the multi-point pressing type sheet material of the present invention is mainly composed of several forming areas and many basic body units; it divides the upper or lower basic body group of the multi-point forming device into several forming areas. A plurality of basic units are arranged in the forming area; when the plate is formed, several forming areas are divided into two or more groups, and each group is divided into one or more forming areas, and the forming plate is pressed step by step in groups. The several forming areas can be divided into multiple areas in a row according to the longitudinal or horizontal direction of the multi-point digital mold, or can be divided into multiple areas in the horizontal and vertical directions, and can also be divided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com