Linear bearing platform type component high-precision steel bar arrangement method

A steel bar layout and steel bar technology, applied in image data processing, 3D modeling, instruments, etc., can solve the problems of low efficiency, time-consuming and labor-intensive, etc., and achieve the effect of improving accuracy, saving construction operation time, and improving the accuracy of steel bar layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] The model in the implementation process is constructed using the BIM modeling platform Revit software released by Autodesk.

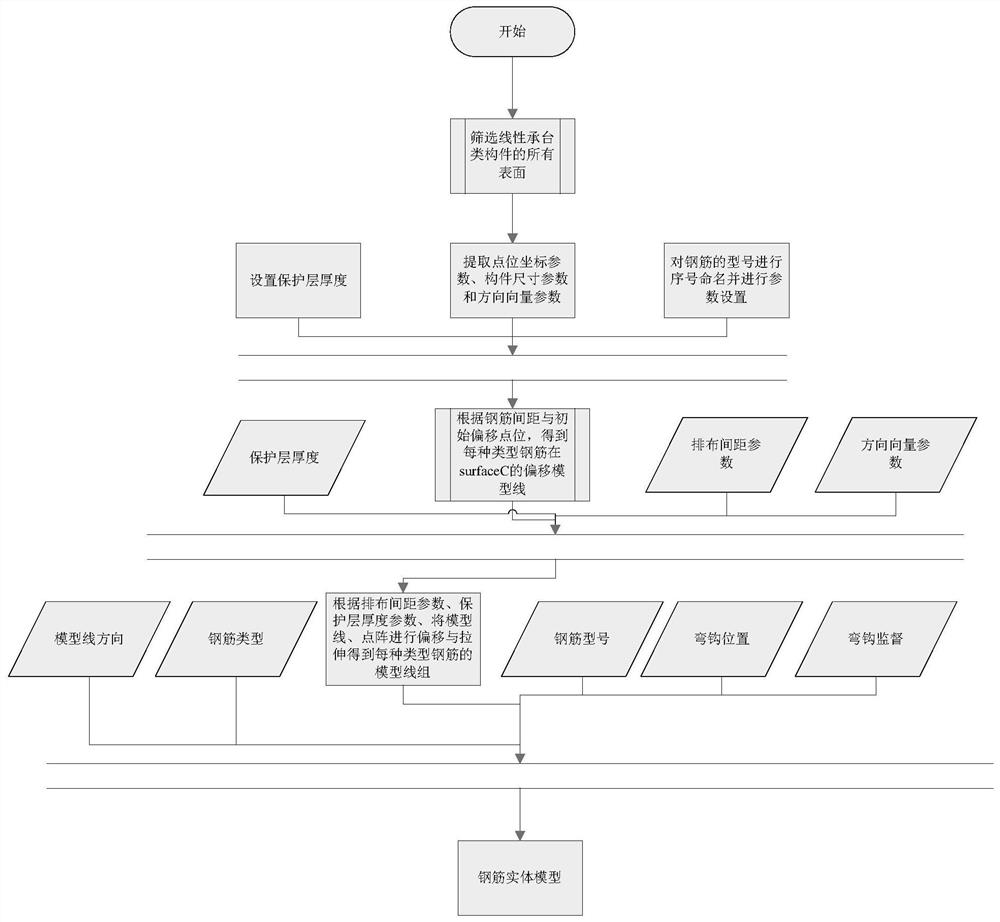

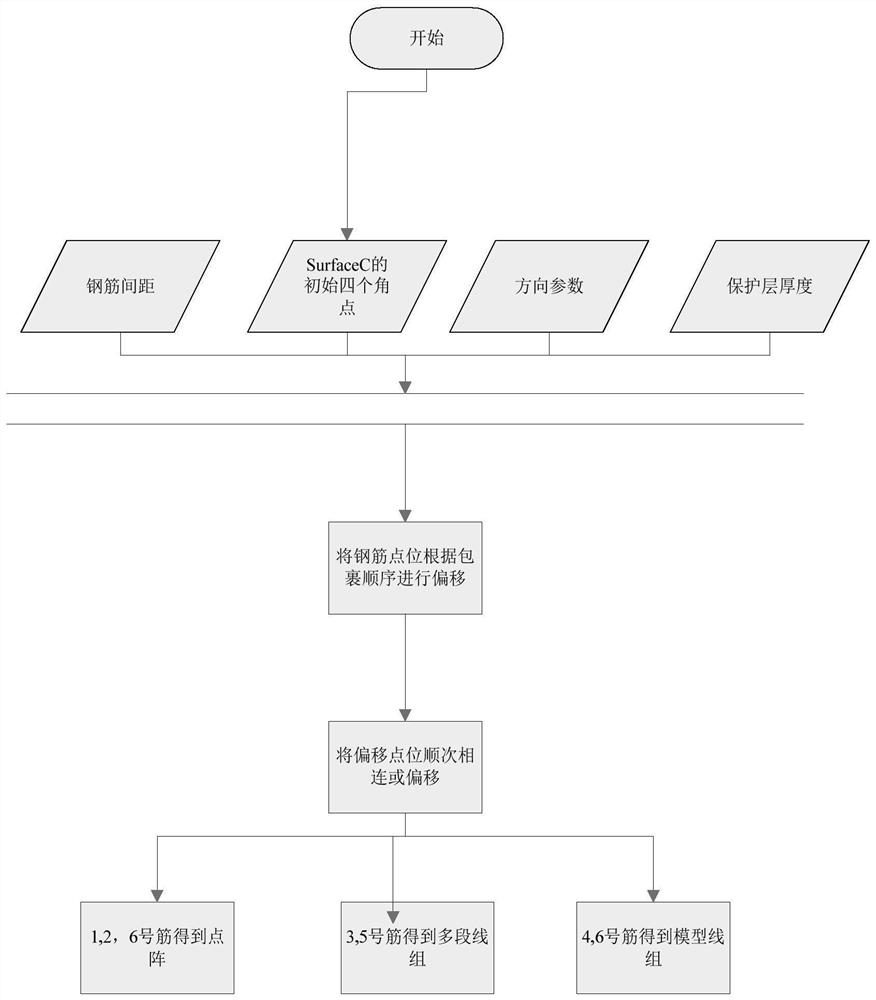

[0026] Above-mentioned content of the invention can be realized by computer programming language, uses DesignScript language to carry out programming under the environment of Dynamo, construction steps are as follows (see figure 1 ):

[0027] Step 1: In the already established structural BIM model, select the linear cap components for which internal reinforcement is to be arranged

[0028] 1. Obtain the component ID of the component.

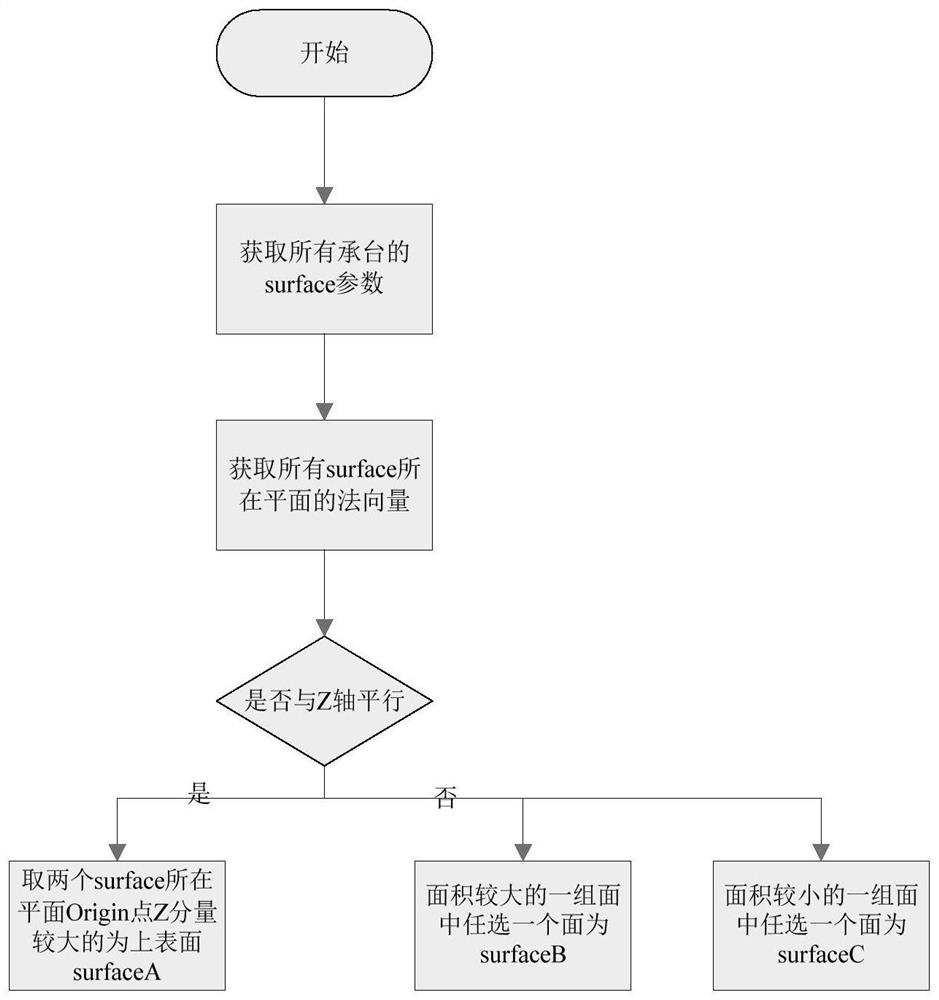

[0029] Step 2: Screen all surfaces of linear cap members (see figure 2 )

[0030] 1. Get all the surfaces of the linear platform components, and get the normal vectors of the planes where all the surfaces are located.

[0031] 2. Determine whether the normal vectors of all surfaces are paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com