Adsorption type garbage picking-up device

A pick-up device and adsorption-type technology, which is applied in cleaning methods, road surface cleaning, construction, etc., can solve the problems of increased labor intensity of sanitation workers, difficulty in picking up accurately, and troublesome device operation, so as to improve labor efficiency, facilitate operation, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

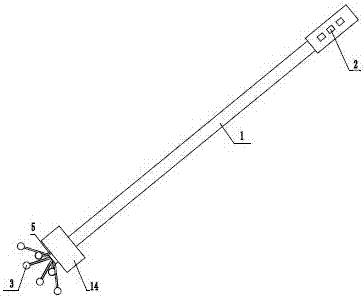

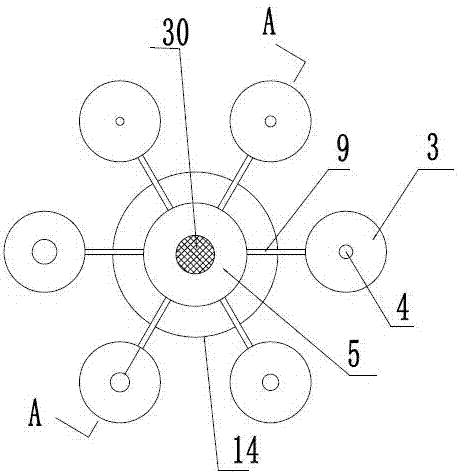

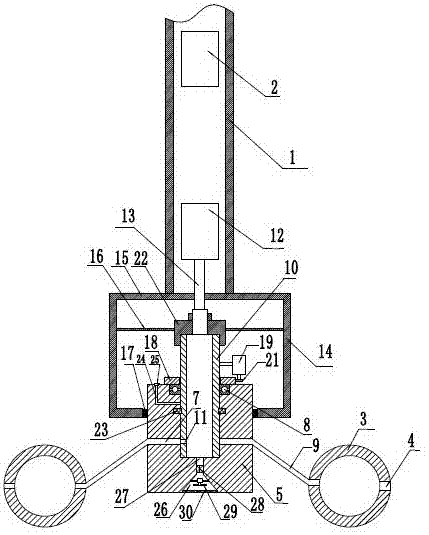

[0023] as attached figure 1 , attached figure 2 As shown, the adsorption-type garbage picking device provided in this embodiment includes an operating rod 1, a controller 2 and a pick-up head on which the operating rod is arranged, and the pick-up head is composed of six adsorption balls 3 .

[0024] combined with figure 2 and attached image 3 As shown, the adsorption ball 3 is a hollow sphere, and the adsorption ball 3 is provided with an adsorption hole 4 connected with the inner cavity of the ball. The adsorption hole 4 is aligned with the object to be picked up. Adsorbed on the surface of the adsorption ball 3, so as to achieve the purpose of picking up. In order to ensure the required adsorption area for different volumes of objects to be picked up, the diameters of the adsorption holes 4 on the six adsorption balls are set differently, and the diameter settings can be set between 5-30mm.

[0025] At the same time, in order to ensure that the adsorption holes of di...

Embodiment 2

[0039] as attached image 3 and attached Figure 4 As shown, in order to ensure the tightness between the vacuum suction pipe 10 and the wall of the counterbore 6 when the vacuum suction pipe 10 is sucking, to ensure that the negative pressure is generated in the adsorption ball 3, an annular sealing ring 23 is provided on the inner wall of the counterbore 6, The sealing ring 23 is located on the inner wall of the counterbore above the through hole 7 .

[0040] Since the rotating head 5 rotates around the vacuum suction pipe 10, a certain degree of lubricity should be guaranteed between the two, as attached image 3 and attached Figure 4 As shown, the top of the rotary head 5 is provided with an oil injection channel 24 that penetrates the counterbore 6, and the top of the oil injection channel 24 is provided with a sealing plug 25. By regularly injecting lubricating oil into the oil injection channel 24 to ensure that the rotary head 5 and the vacuum suction tube Lubricat...

Embodiment 3

[0042] as attached image 3 and attached Figure 4 As shown, the bottom surface of the rotary head 5 is provided with an air suction port 26 extending to the inside of the rotary head. The air suction port 26 is bell-shaped. 27 is provided with a control valve 28, and an inlet fan 29 is arranged inside the air suction port, and the inlet fan 19 is electrically connected with the controller 2. In order to prevent large sundries from being sucked into the air suction port 26, as attached image 3 and attached Figure 4 As shown, a filter screen 30 is provided at the bottom opening of the air suction port.

[0043] The effect of setting the above-mentioned means in this embodiment is that after the adsorption ball 3 is adsorbed to the object to be picked up, in the process of delivering the garbage bag, when the negative pressure effect is lost in the inner cavity of the adsorption ball 3, some heavier The picked up object can fall into the garbage bag by its own weight, but ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com