Machine vision-based intelligent control method and machine vision-based intelligent control system for industrial robot

An industrial robot and machine vision technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of inability to implement changes in the collection of on-site signal operations, insufficient flexibility and intelligence of robots, and achieve economical and simple integration and maintenance, software and hardware interaction. Strong changeability and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

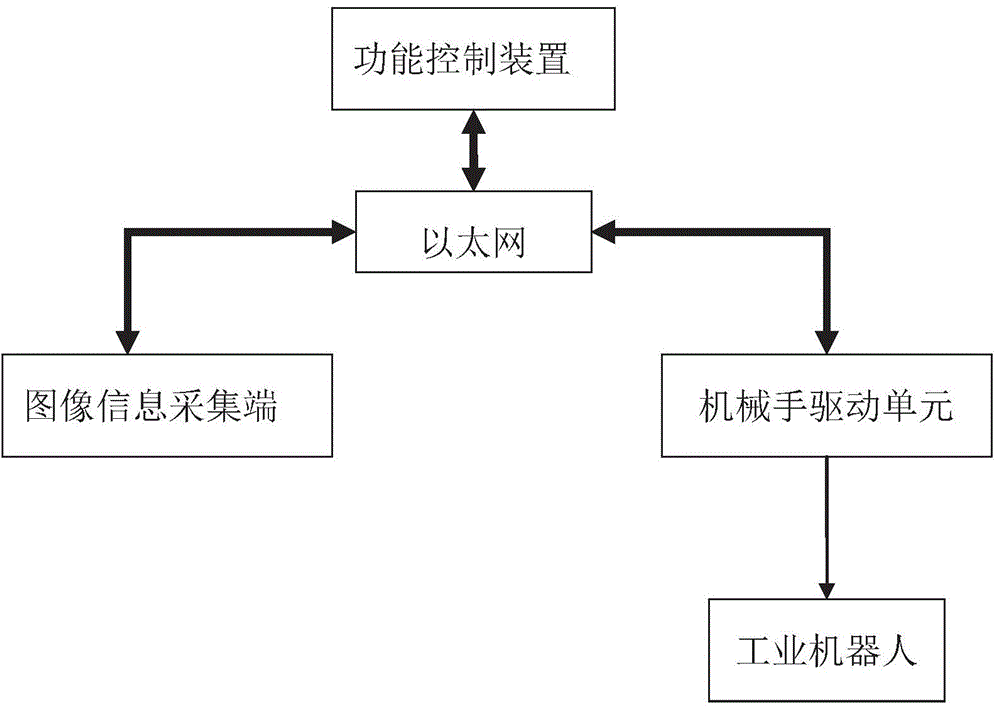

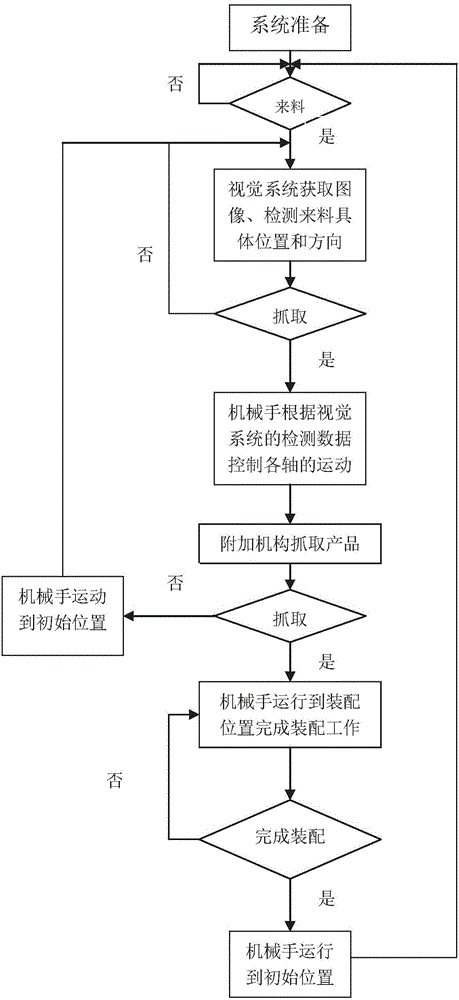

[0027] Example: see figure 1 and figure 2 , the present embodiment provides an intelligent control method for an industrial robot based on machine vision, which includes the following steps:

[0028] (1) Based on GigE Vision Gigabit Ethernet image transmission, an image information acquisition terminal is set, which includes at least one camera and its control circuit, to collect information sources;

[0029] (2) A function control device is set, and an integrated circuit board is arranged in the device, and an I / O function module, a data storage function module, a central processing module, a data calculation module and a wireless transmission function module are integrated on the circuit board;

[0030] (3) An industrial robot based on the EtherCAT field bus system is set, which includes a mechanical arm and a drive unit;

[0031] (4) When working, when the incoming material enters the shooting range of the camera, the image information acquisition terminal transmits the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com