Tooling test system and tooling test control method

A test system and test control technology, applied in the direction of electronic circuit testing, printed circuit testing, measuring electricity, etc., can solve problems such as labor consumption, and achieve the effect of solving labor consumption, saving labor operation, and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

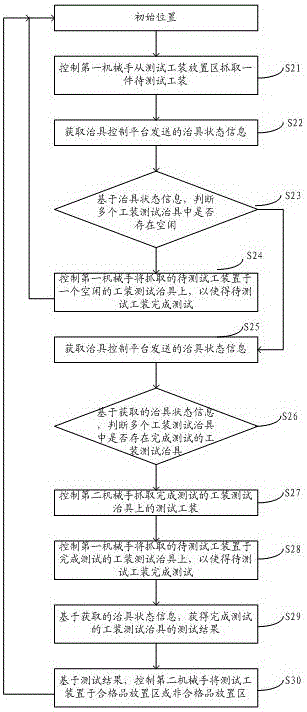

[0022] The specific implementation manners of the present application will be described in further detail below in conjunction with the accompanying drawings.

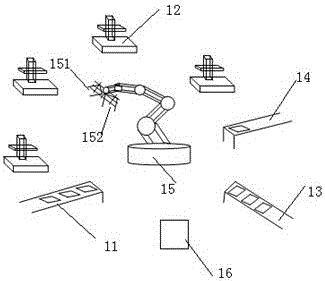

[0023] This application proposes a tooling testing system, such as figure 1 As shown, it includes a test tool placement area 11, a plurality of tool test fixtures 12, a qualified product placement area 13, a non-qualified product placement area 14, a gripper robot 15 and a fixture control platform 16.

[0024] The control center of the gripper robot 15 is interconnected with the fixture control platform 16; the fixture control platform is responsible for controlling and managing multiple tooling test fixtures, and obtains the fixture status information of multiple tooling test fixtures and sends them to the control of the gripper robot The center; the gripper robot 15 includes a first manipulator 151 for grabbing the test tool to be tested from the test tool placement area 11, and installing the captured test tool on a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com