Machine lifting tool for automatically grabbing and releasing goods

A cargo and automatic technology, applied in the field of mechanical spreaders, can solve the problems of increased hoisting operation costs, large operating space requirements, and short maintenance and repair cycles, and achieves the effects of simple structure, high work efficiency and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

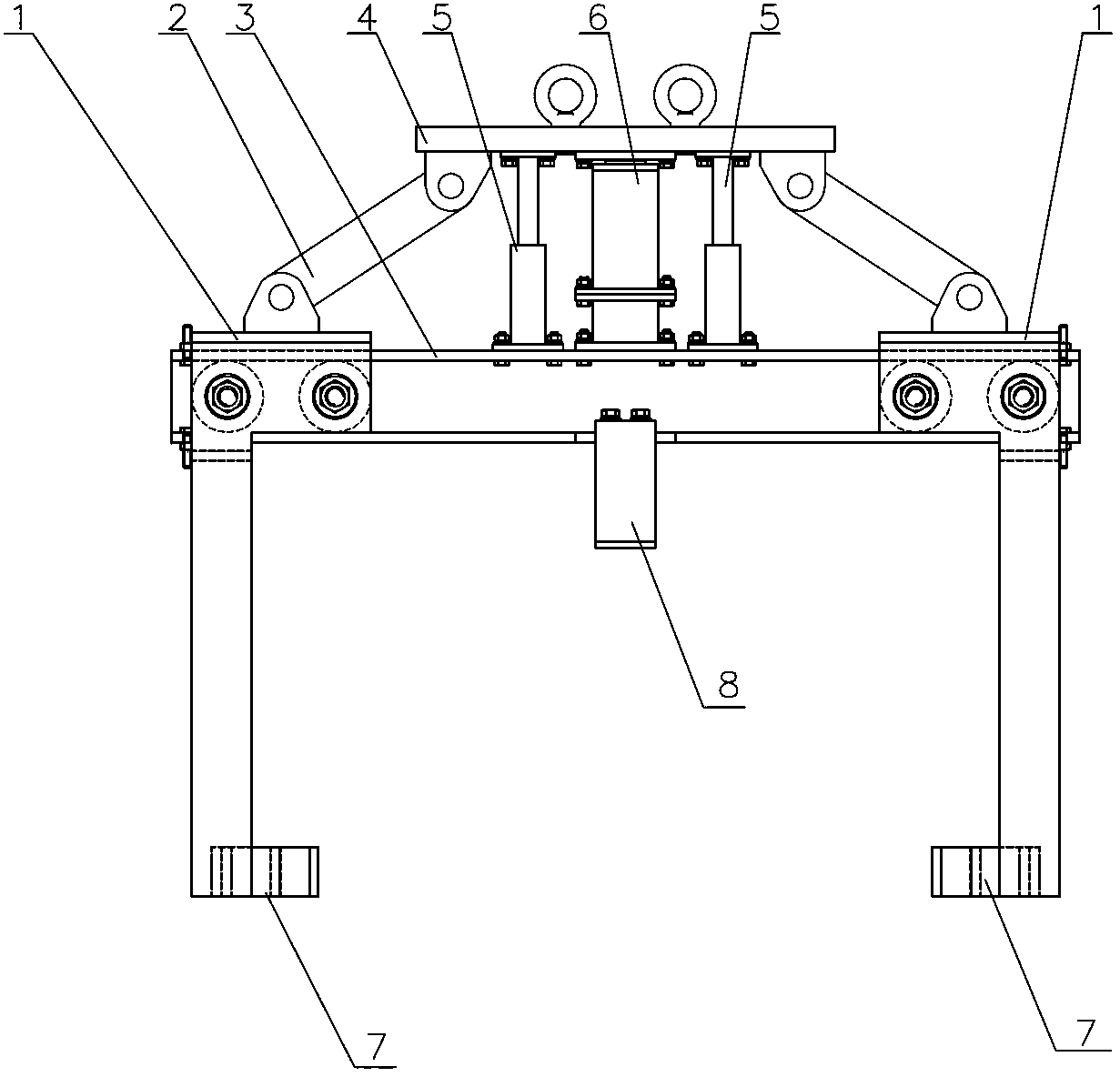

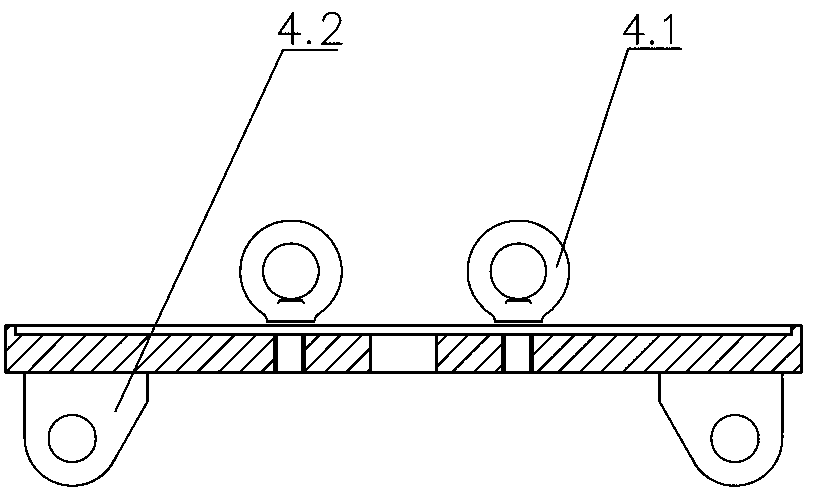

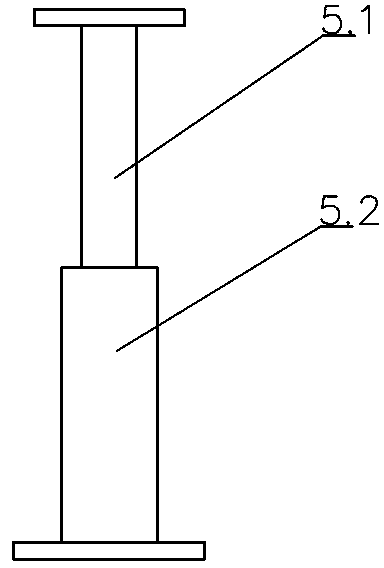

[0042] like Figure 1~15 As shown, the mechanical spreader of the present invention capable of automatically grabbing and releasing goods has a horizontal guide rail 3, the cross section of which is an I-shaped structure, and movable trolleys 1 are installed at both ends thereof. The movable trolley 1 is also welded by steel plates, and its two sides are provided with bearings that roll and cooperate with the horizontal guide rail 3 . The top of the movable trolley 1 is provided with a hinged support 1.1. An arm 7 is arranged at the bottom of the movable trolley 1 . The arm 7 has a long flat plate 7.1, the top of the long flat plate 7.1 is welded to the movable trolley 1, and the bottom of the long flat plate 7.1 is welded to a section of curved plate 7.3 through three sections of ribs 7.2, so as to be suitable for grabbing a barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com