Grabbing and detecting mechanism for parts

A technology of grasping mechanism and detection mechanism, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of easily damaged parts, low efficiency and large errors, and achieve the effect of improving production efficiency, wide application range and reducing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

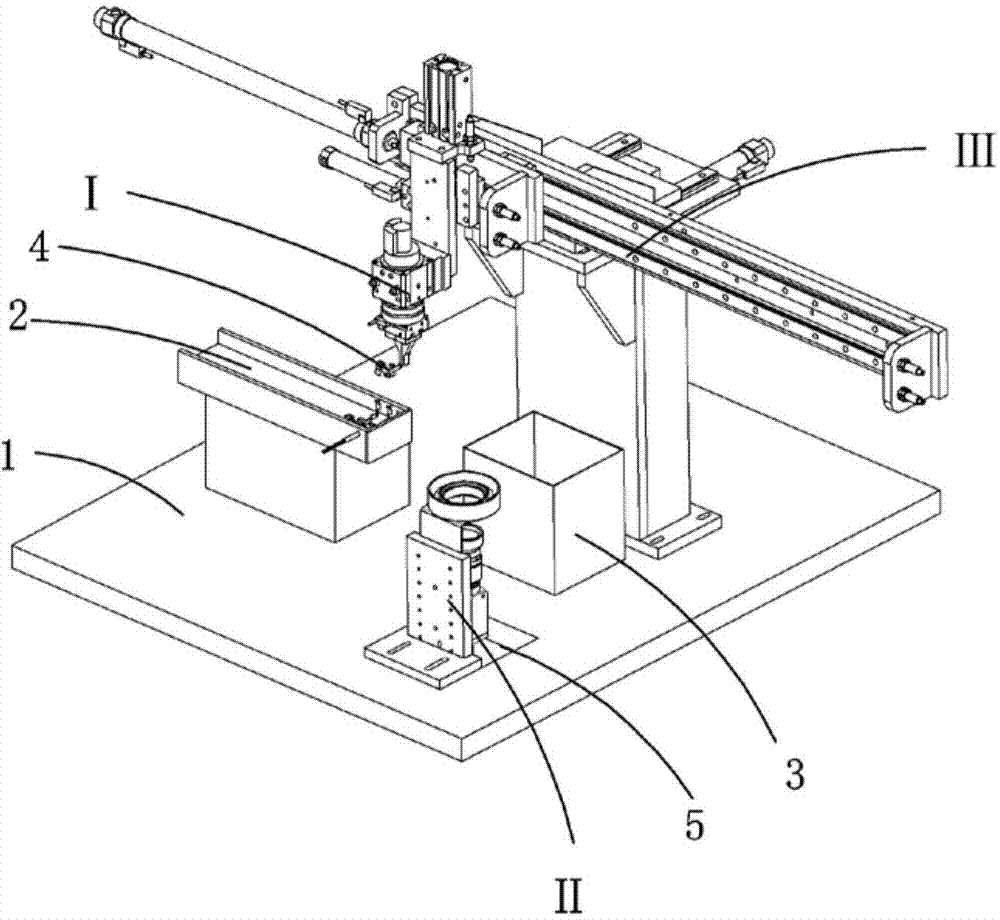

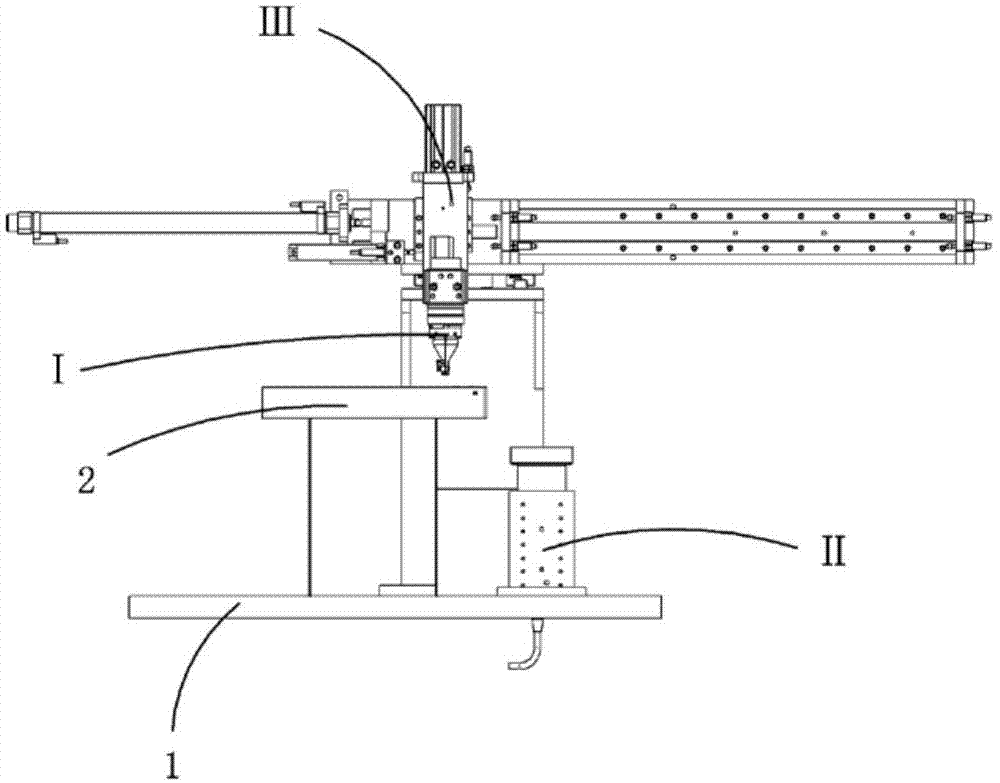

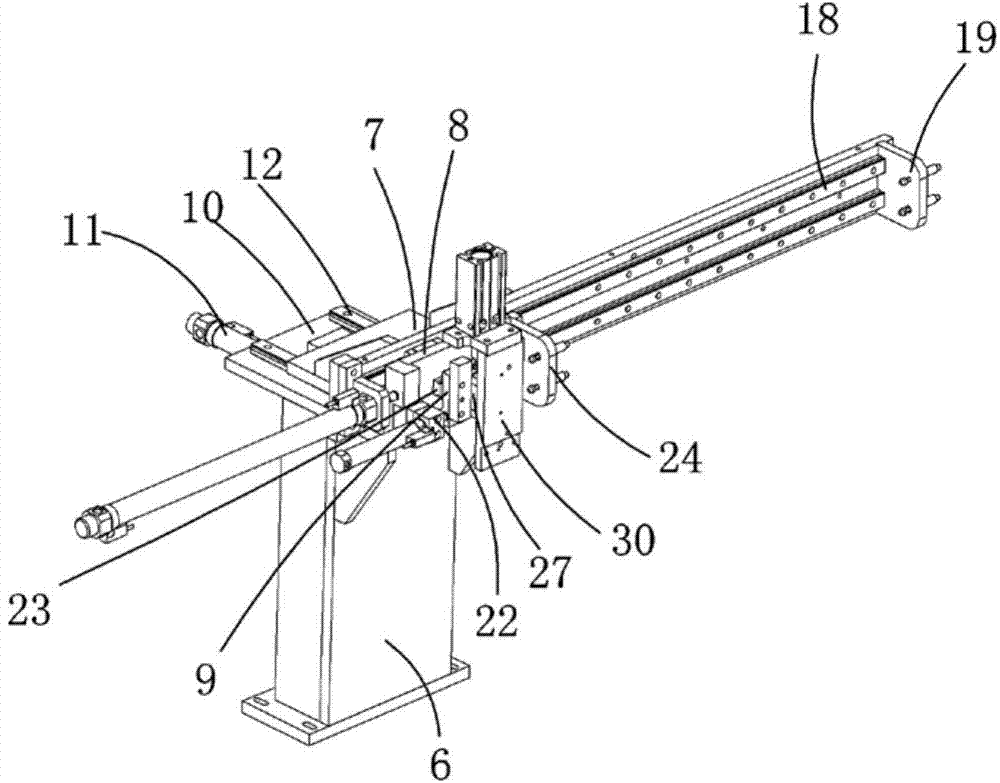

[0023] Examples, see attached Figure 1~6 , a parts grasping inspection mechanism, which includes a bottom plate 1, a grasping mechanism I, a detection mechanism II, a handling mechanism III, a parts warehouse 2 and a defective product warehouse 3, and the parts warehouse and the defective product warehouse are fixed on the bottom plate. The parts 4 are neatly arranged in the parts warehouse; the base plate is provided with a square slot 5, and the detection mechanism is installed on the base plate, and is located at the square slot; On the handling mechanism; the grabbing mechanism is used to grab the neatly arranged parts in the parts warehouse; the detection mechanism is used to detect the appearance and size of the grabbed parts; the handling mechanism is used to realize parts grabbing and inspection actions The displacement of the defective product warehouse is used for the storage of defective products, and the defective products detected by the detection mechanism are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com