Plastic spraying device

A technology of plastic spraying and clamping mechanism, which is applied in the direction of spraying devices, etc., can solve the problems of high labor intensity and low spraying efficiency, and achieve the effects of high automation, high spraying efficiency and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is a further detailed description through specific implementations:

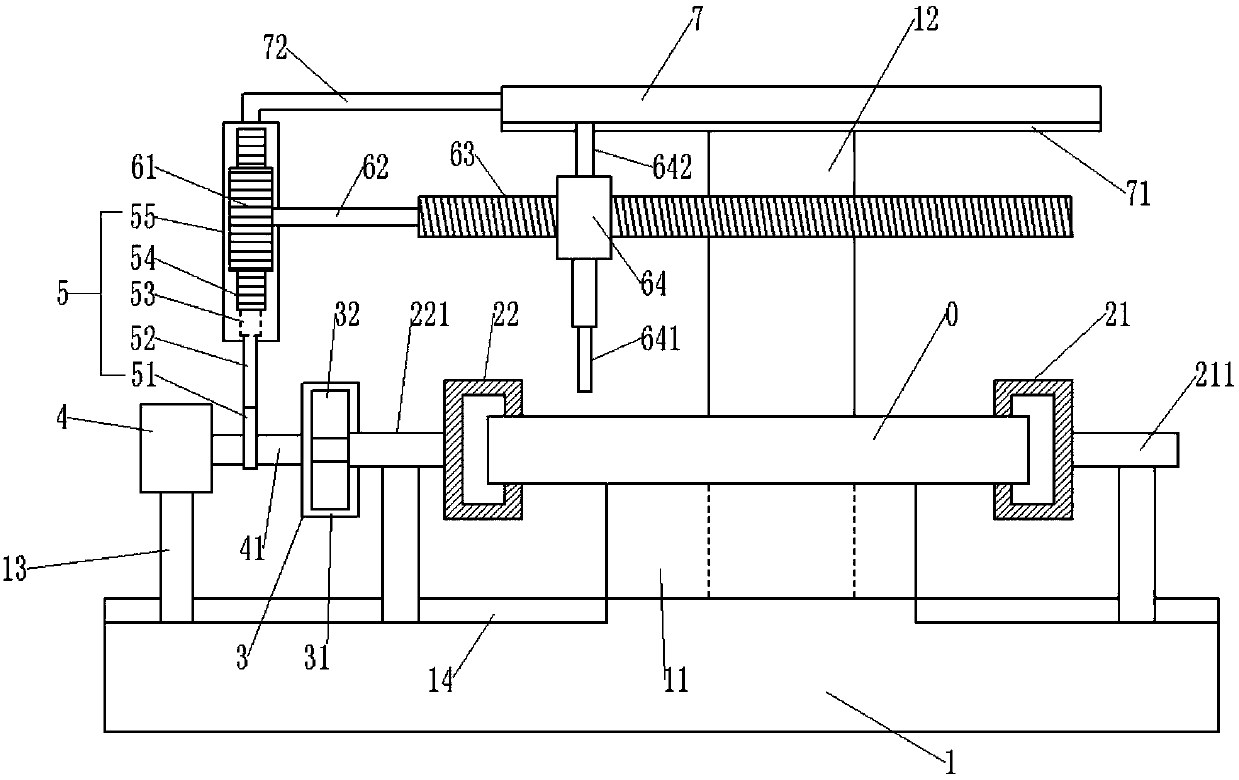

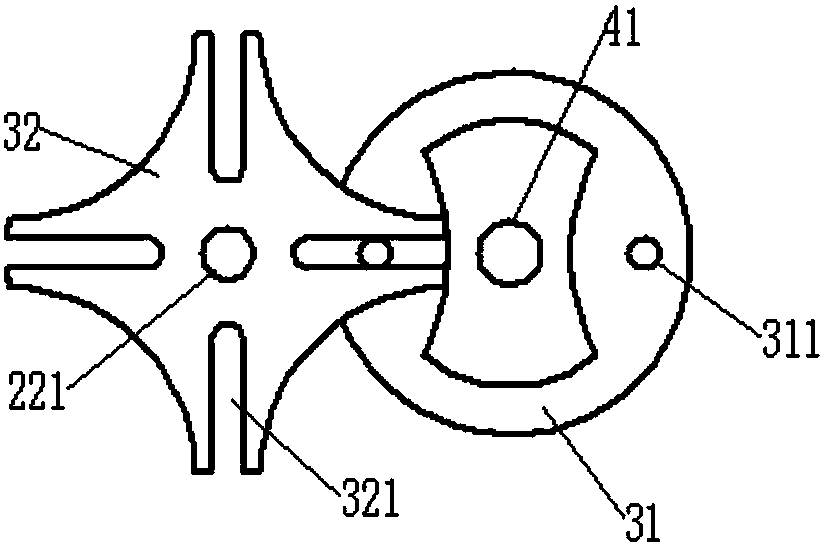

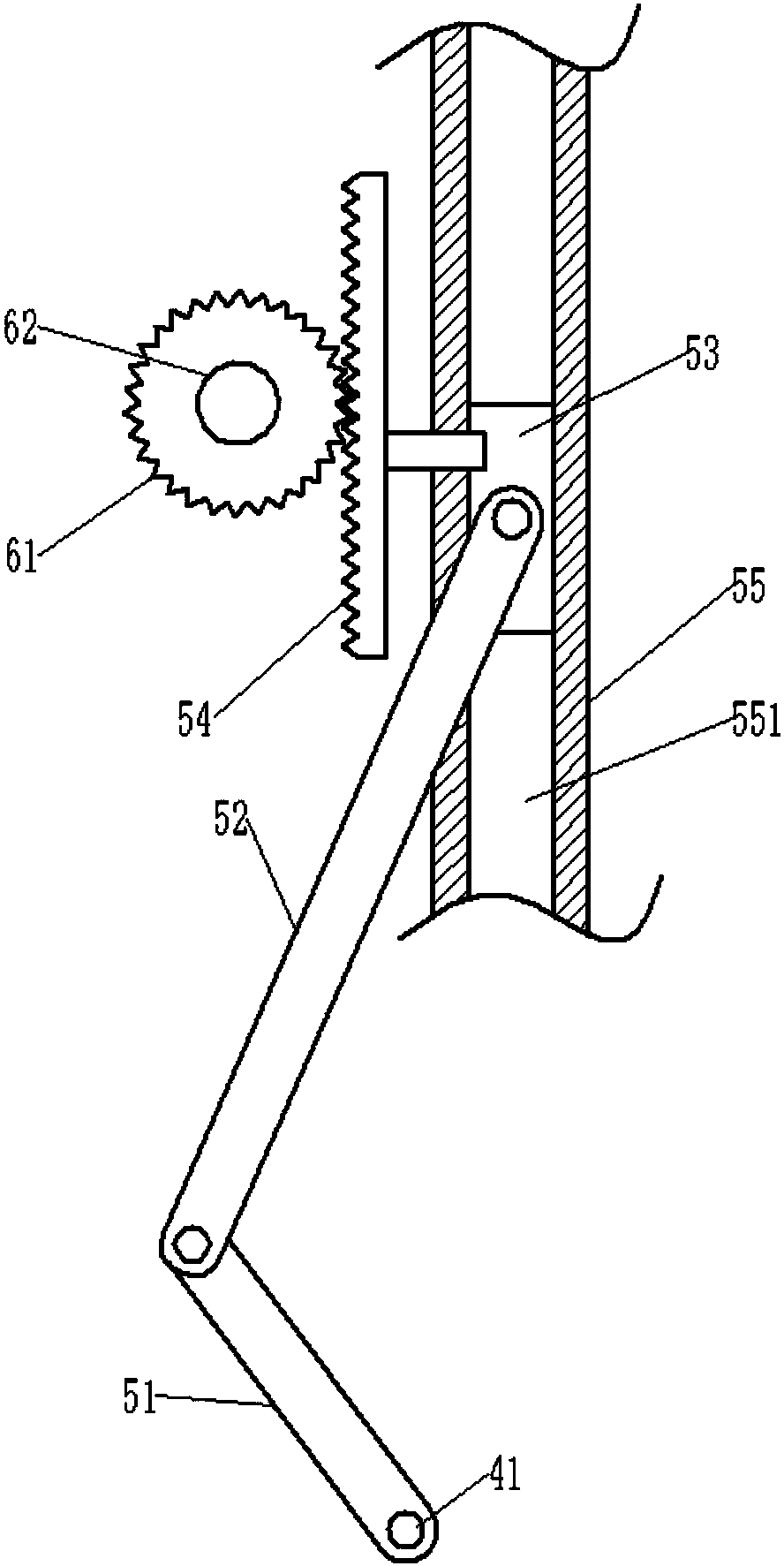

[0019] Instruction attached Figure 1 to 3 The reference signs in include: guardrail 0, support seat 1, support table 11, first support column 12, second support column 13, second chute 14, first clamp 21, cross bar 211, second clamp 22, First rotating shaft 221, groove wheel mechanism 3, driving dial 31, cylindrical pin 311, groove wheel 32, radial groove 321, motor 4, output shaft 41, crank slider mechanism 5, crank 51, connecting rod 52, slider 53. Rack 54, slide rail 55, first slide groove 551, gear 61, second shaft 62, lead screw 63, nut 64, spray gun 641, first connecting rod 642, cross beam 7, third slide groove 71 , Second connecting rod 72.

[0020] The embodiment is basically as attached figure 1 Shown: a spraying device, including a support base 1, a motor 4, a clamping mechanism and a spraying mechanism. The support base 1 is provided with a first support column 12 and a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com