Patents

Literature

34results about How to "Guaranteed labeling quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

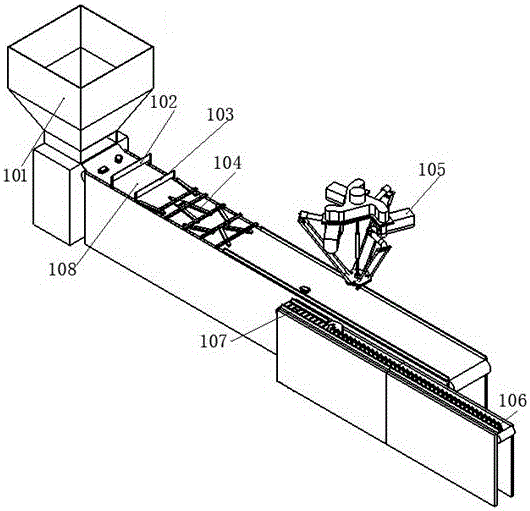

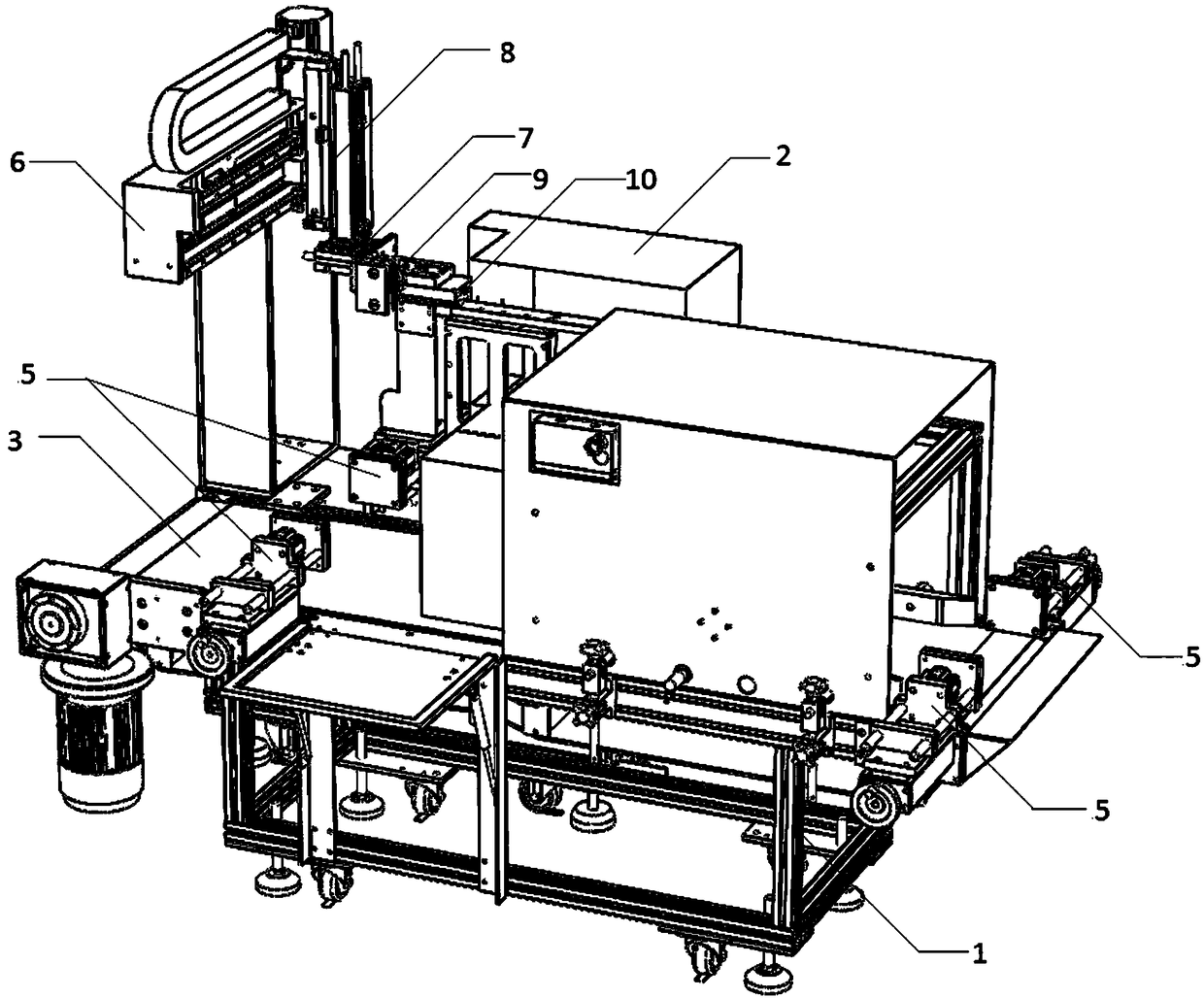

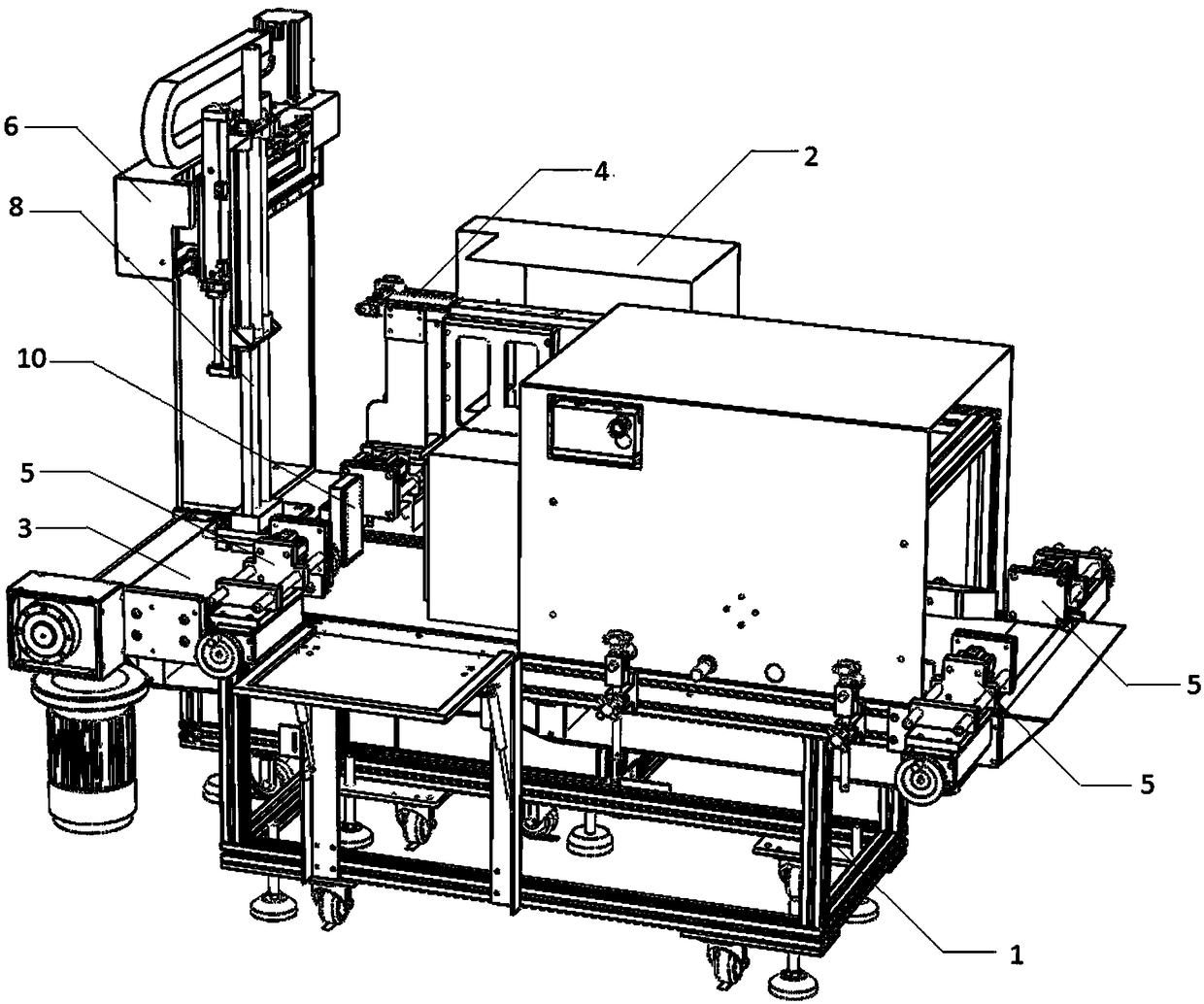

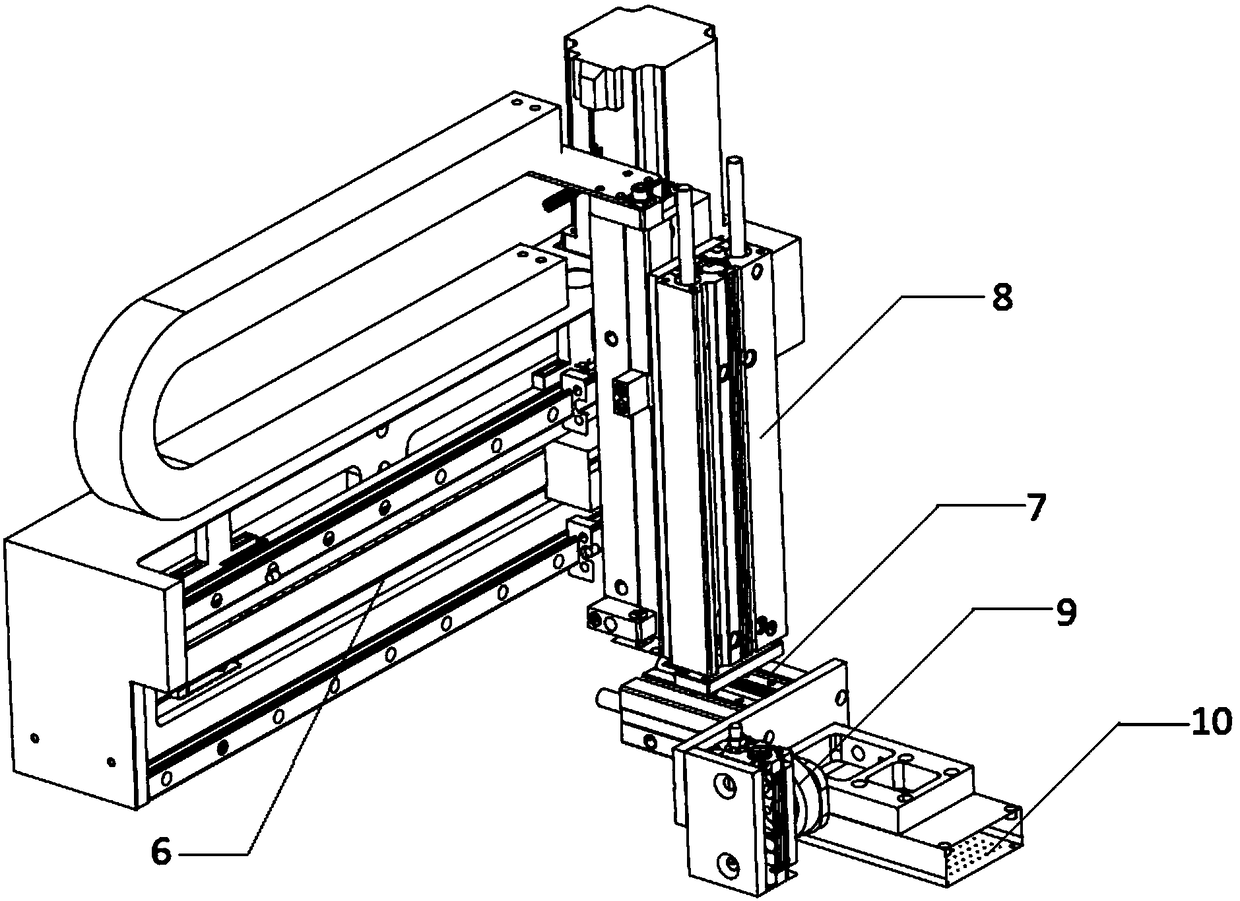

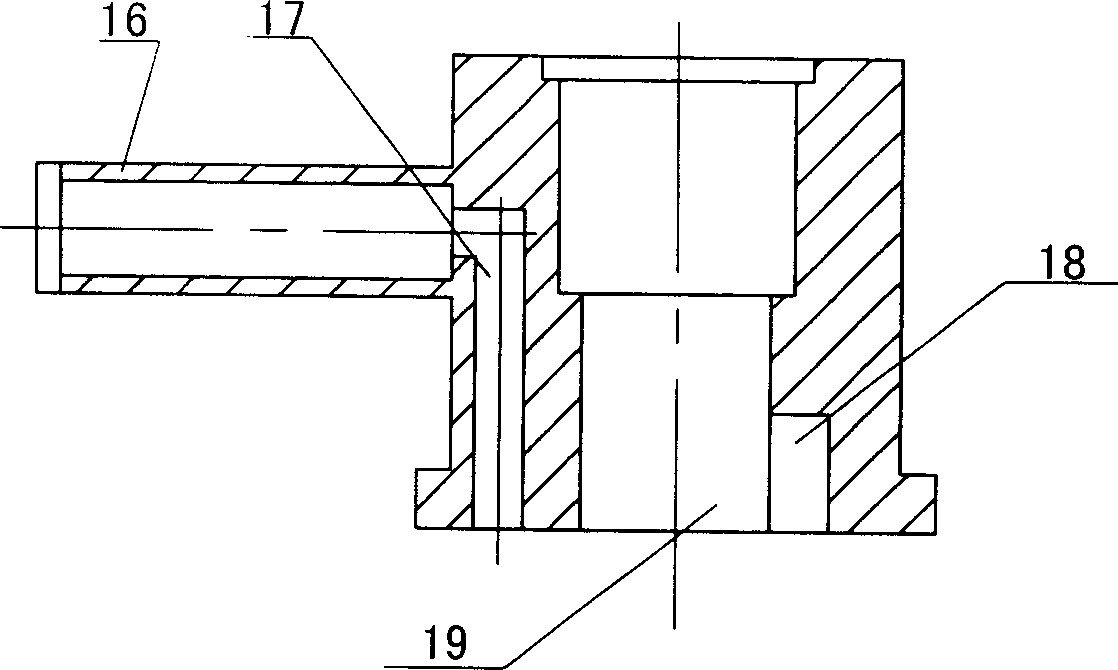

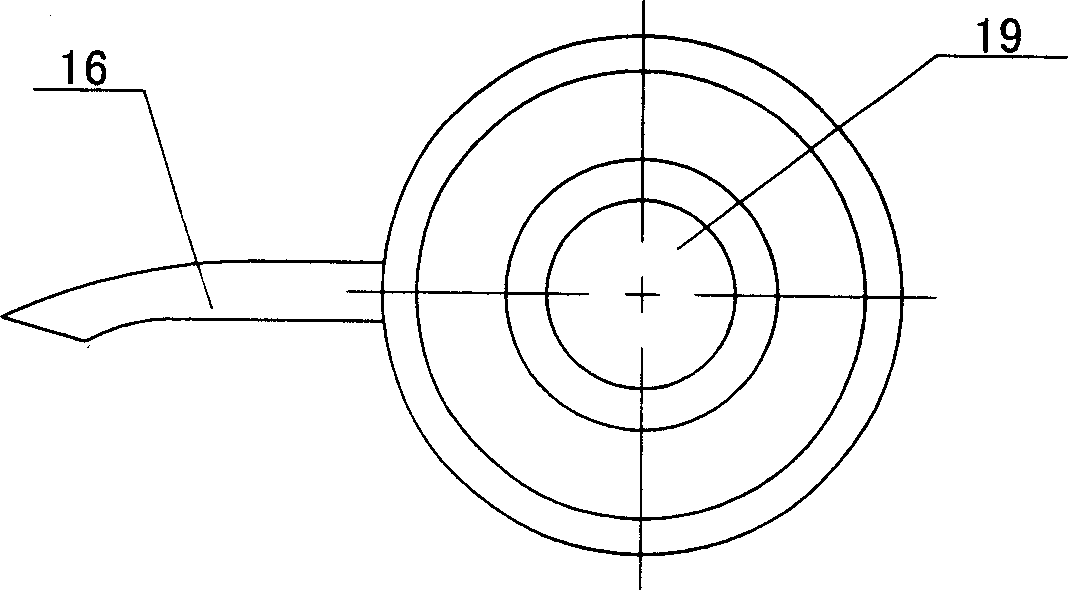

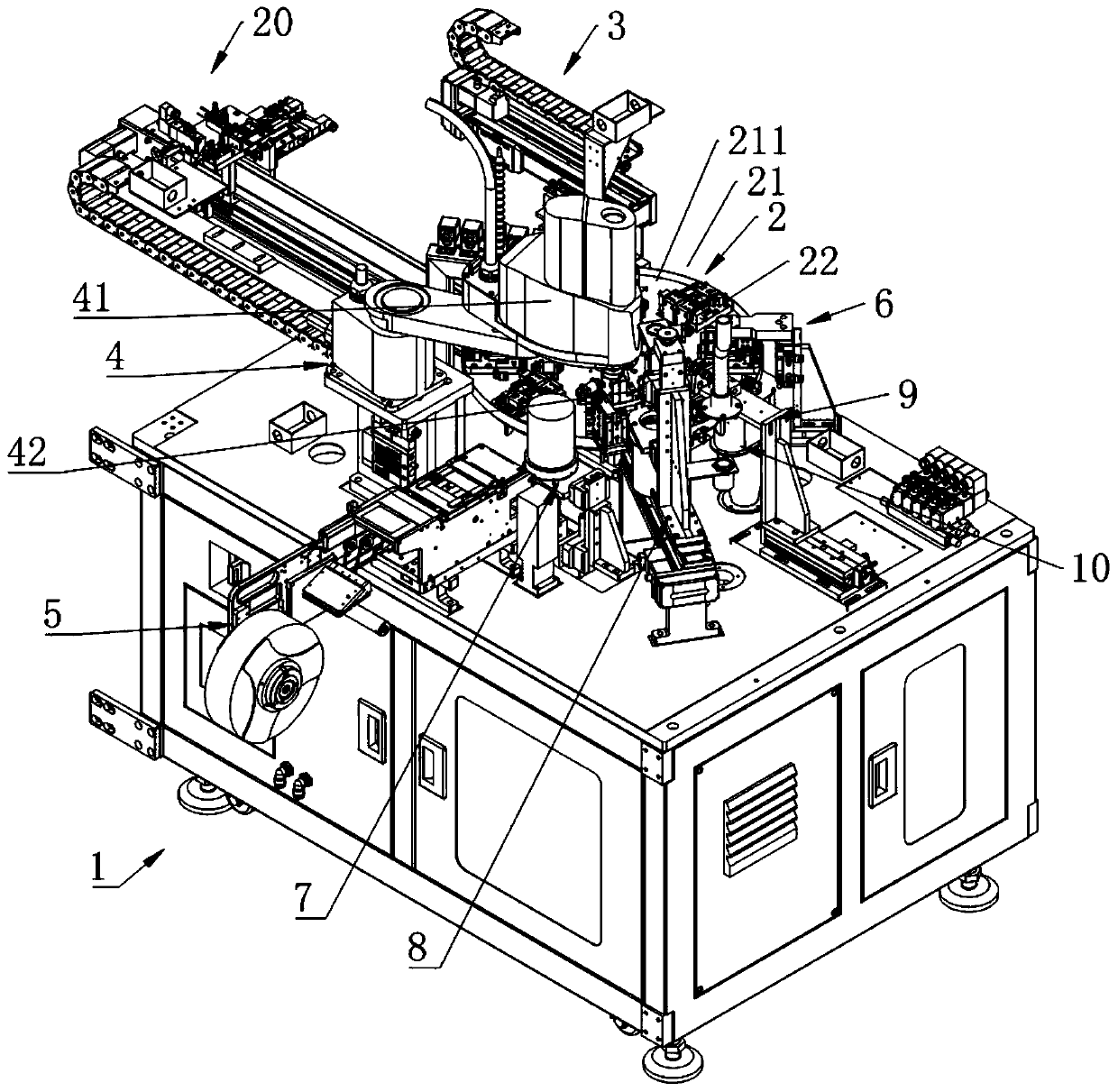

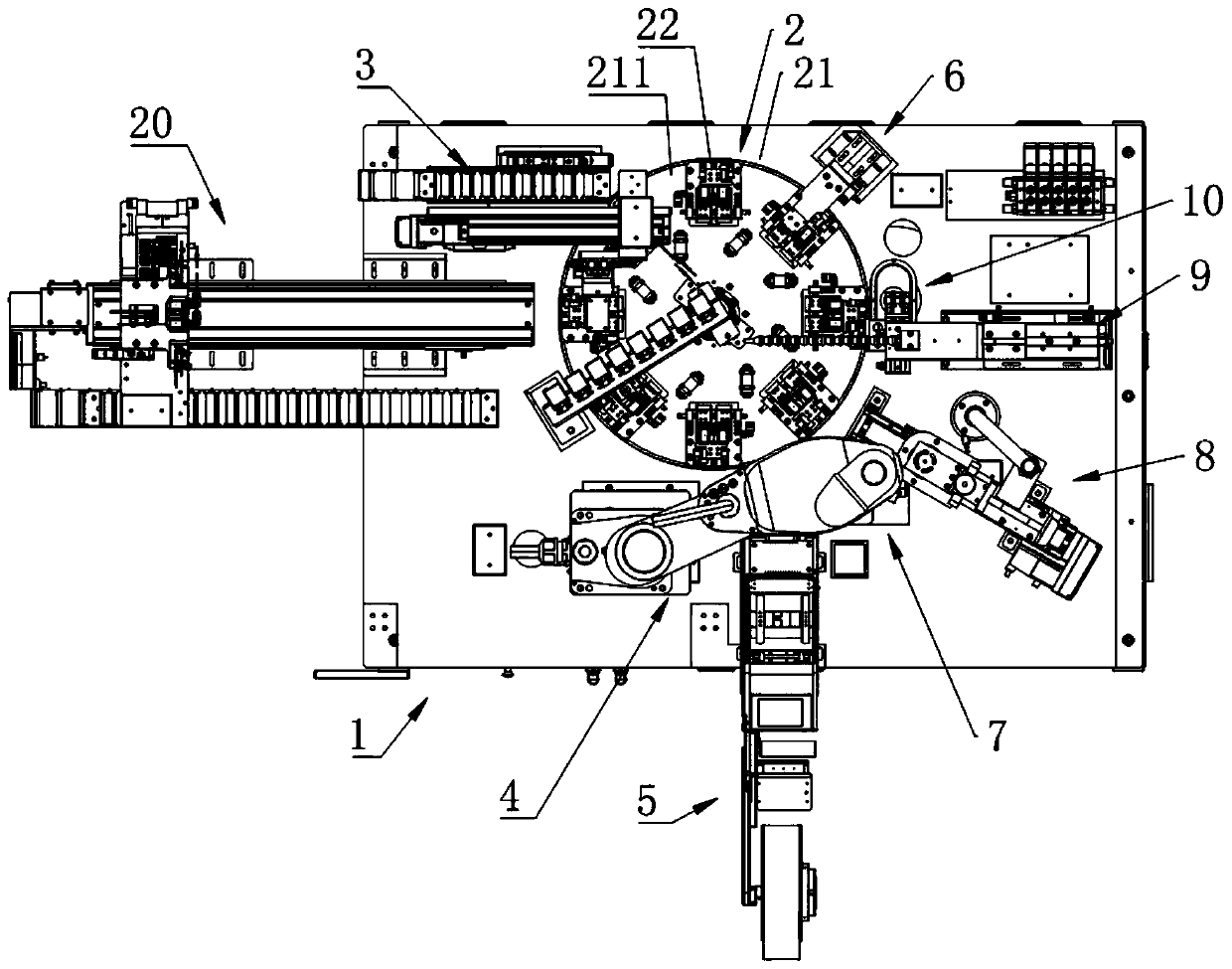

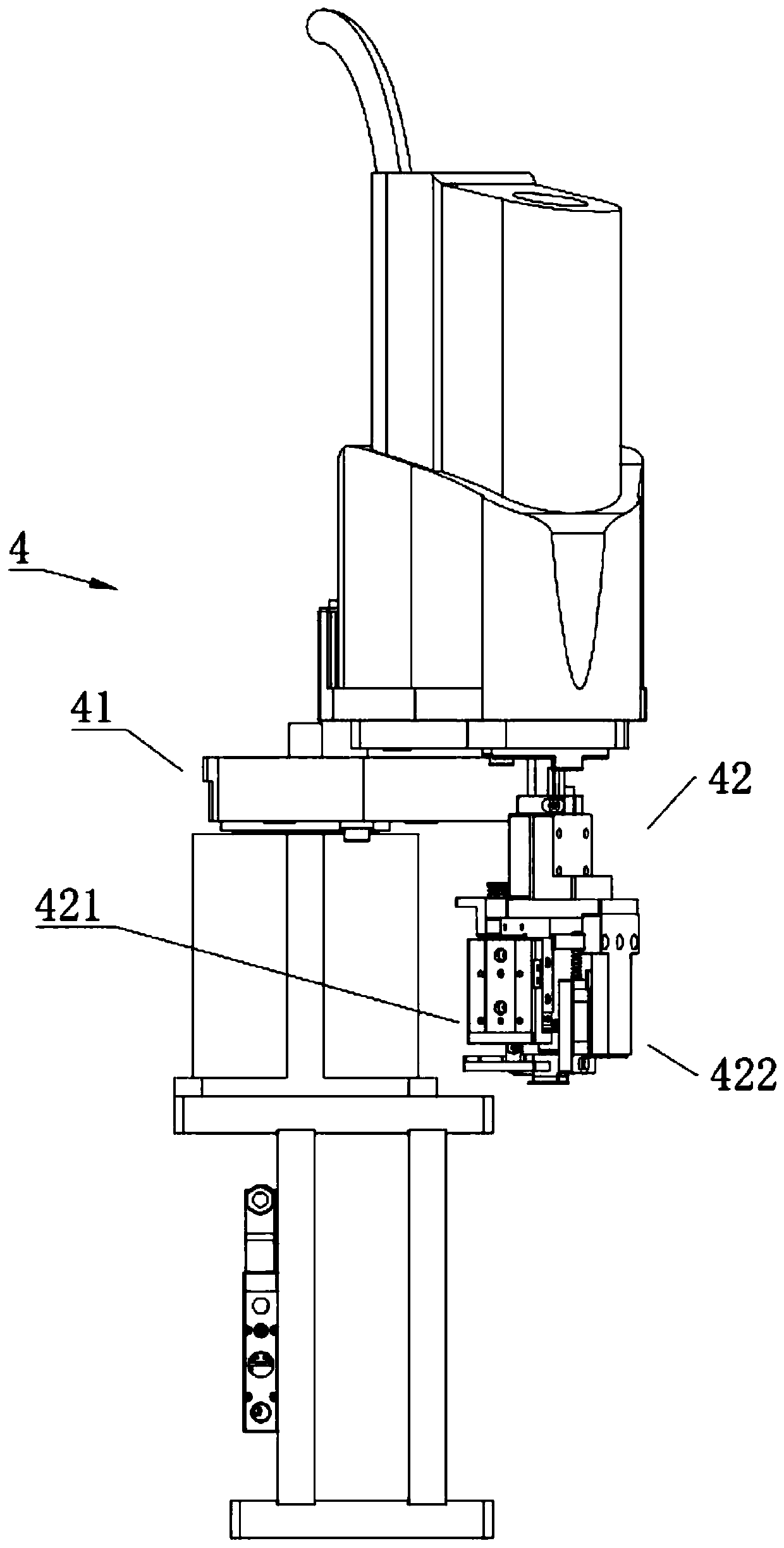

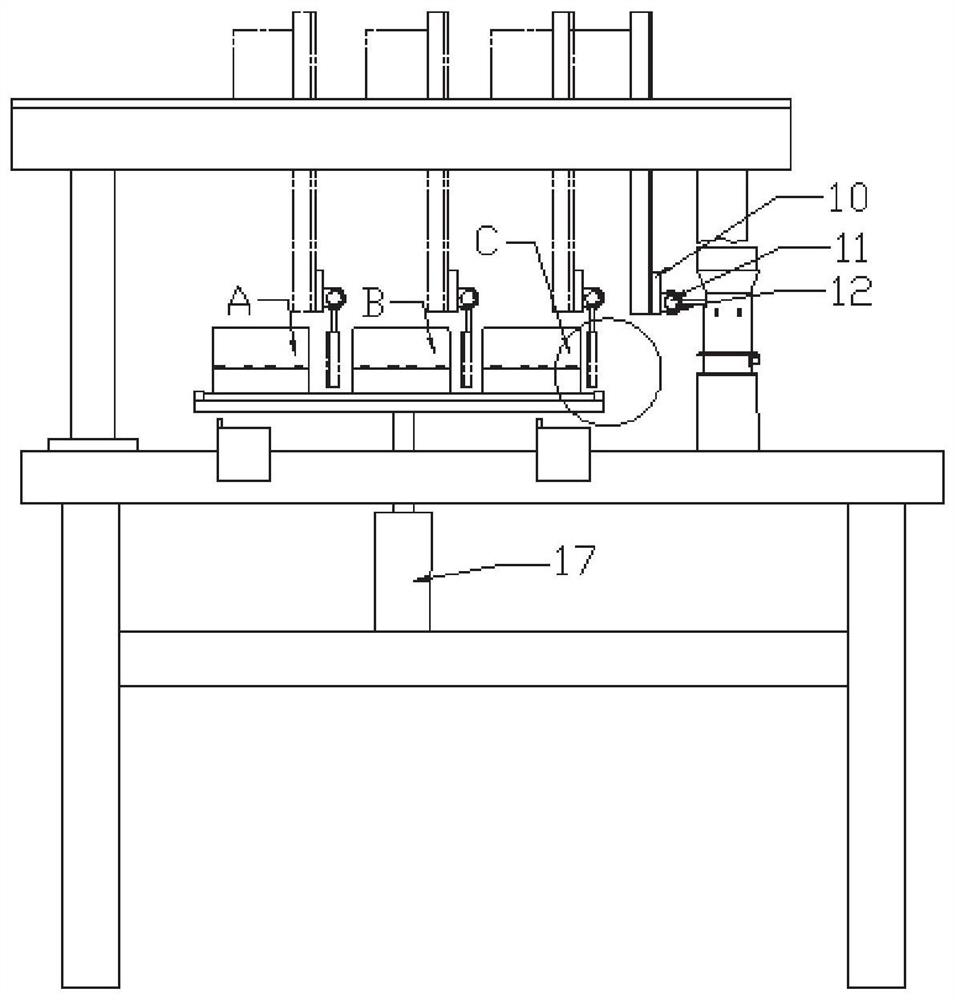

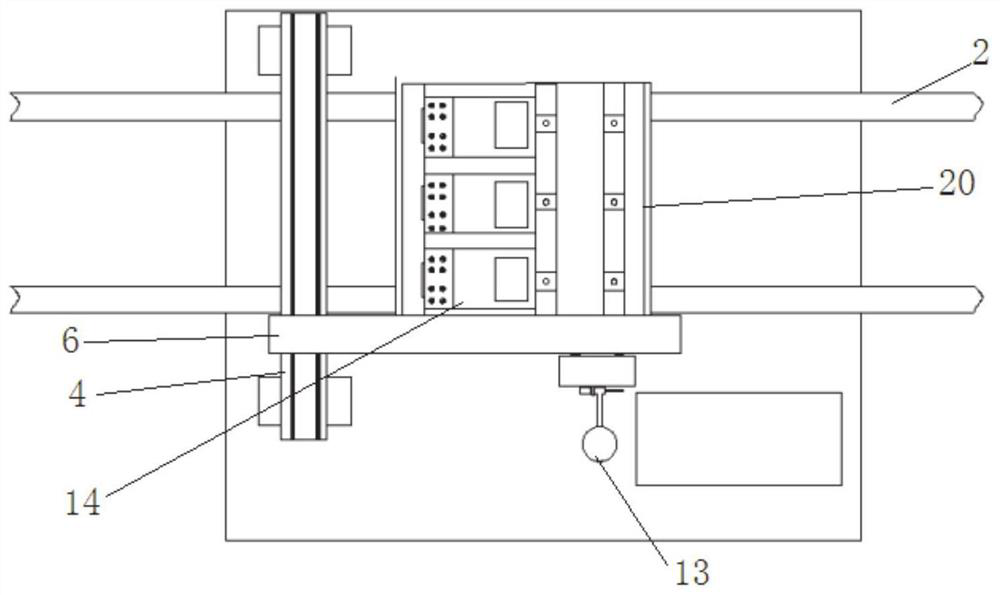

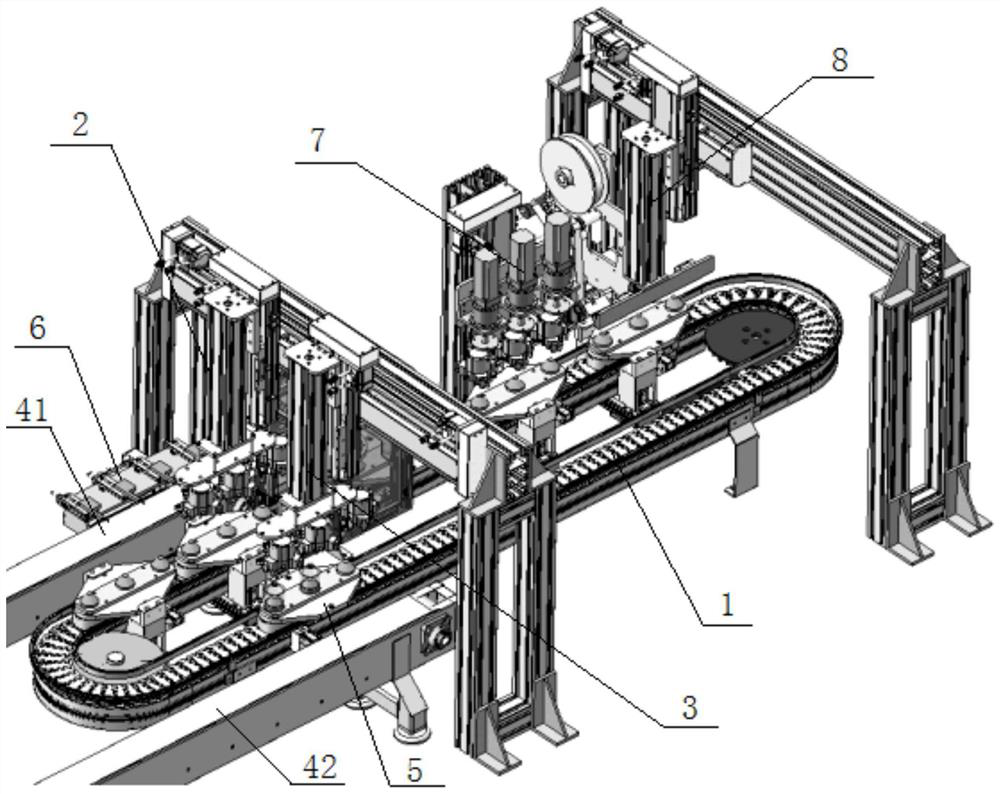

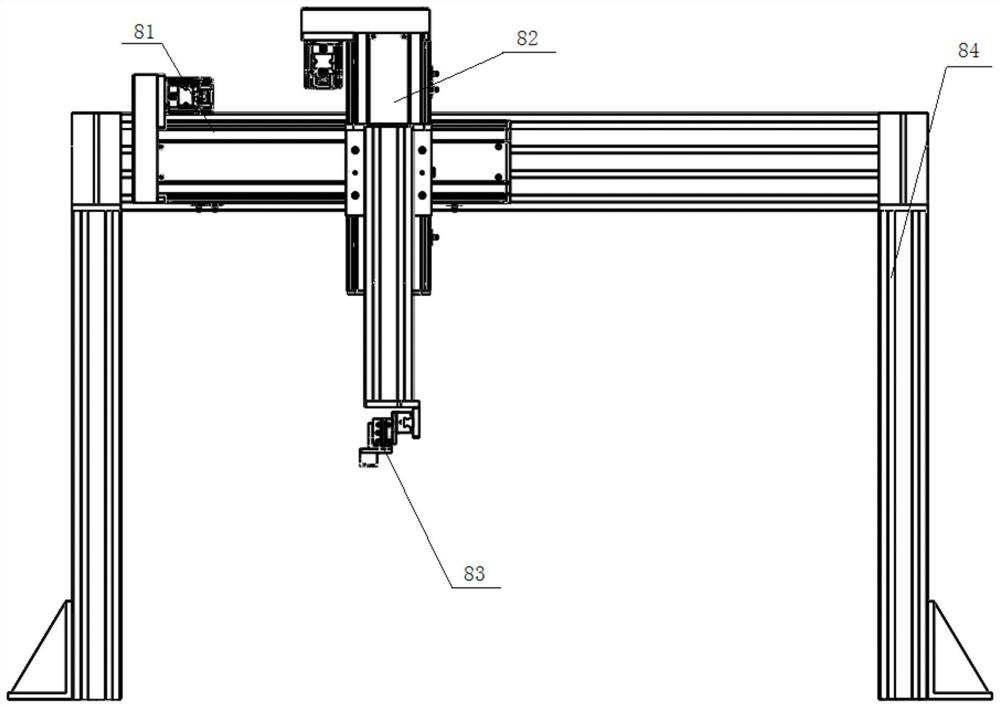

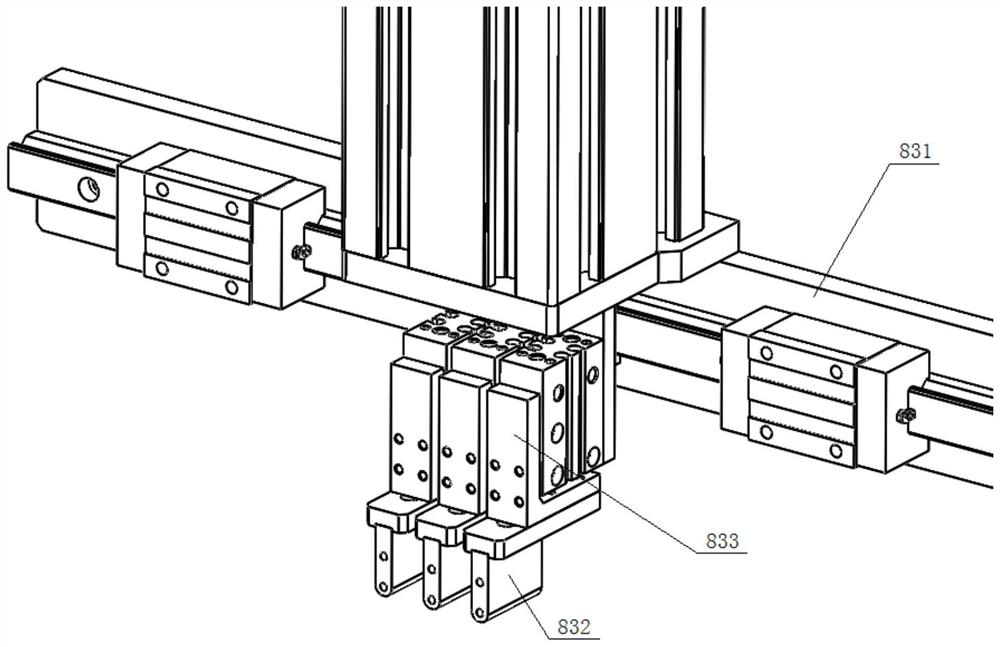

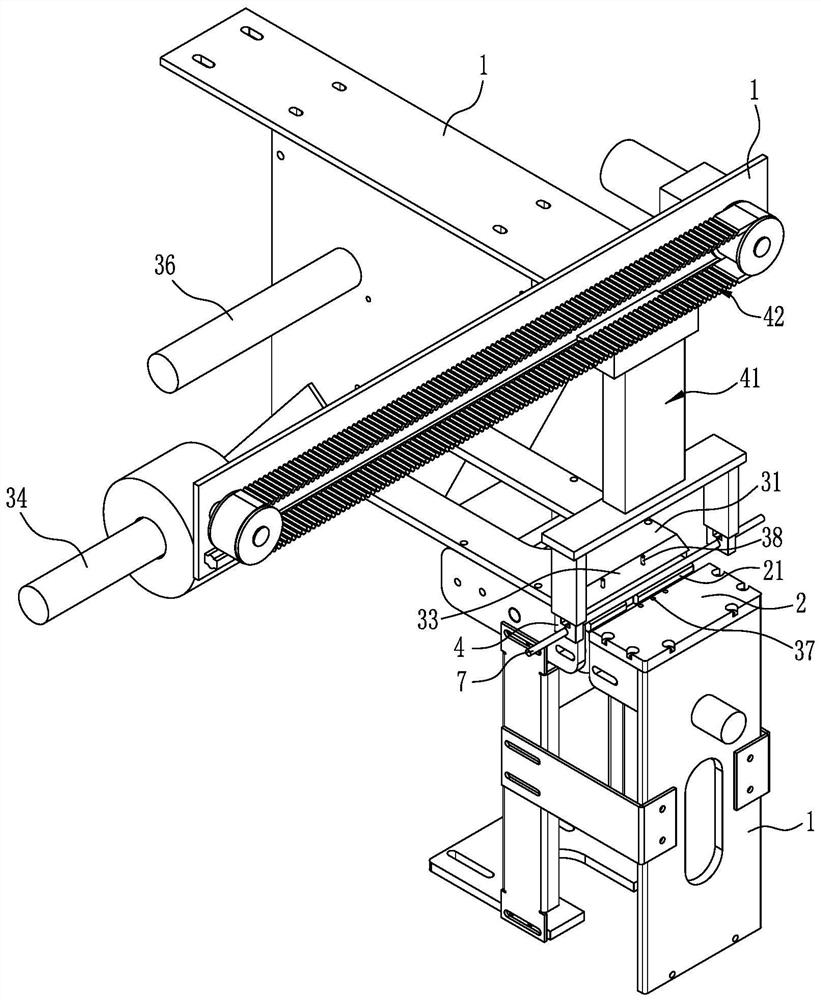

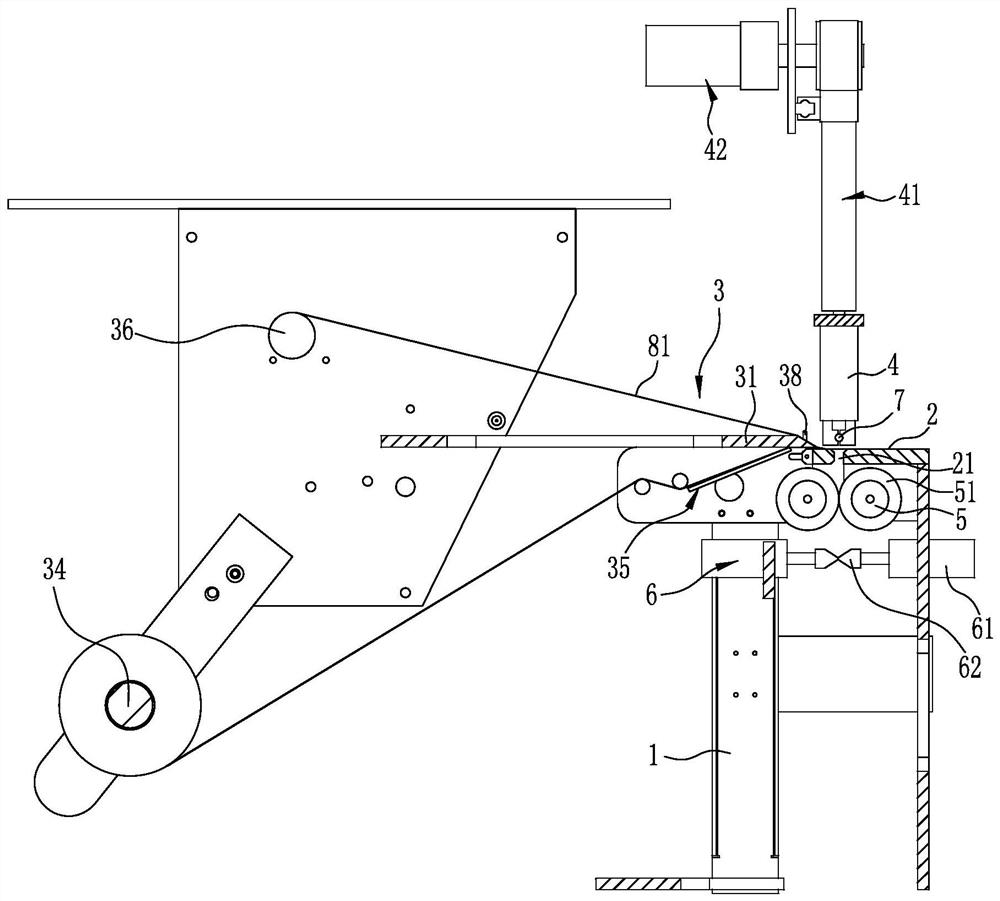

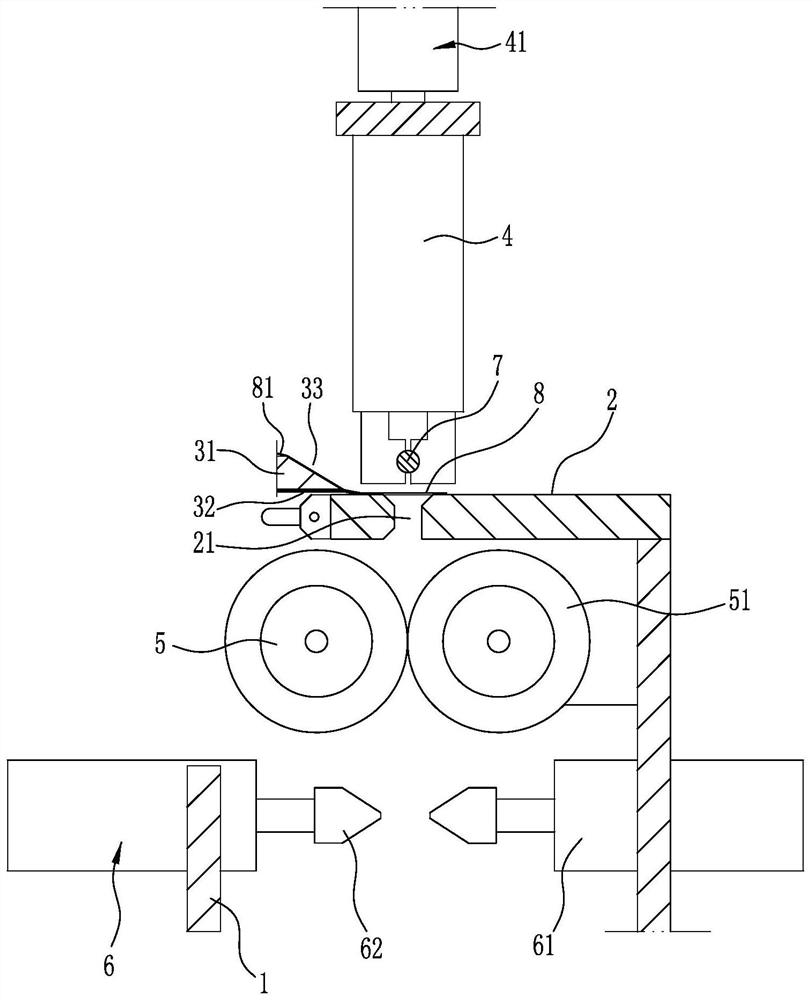

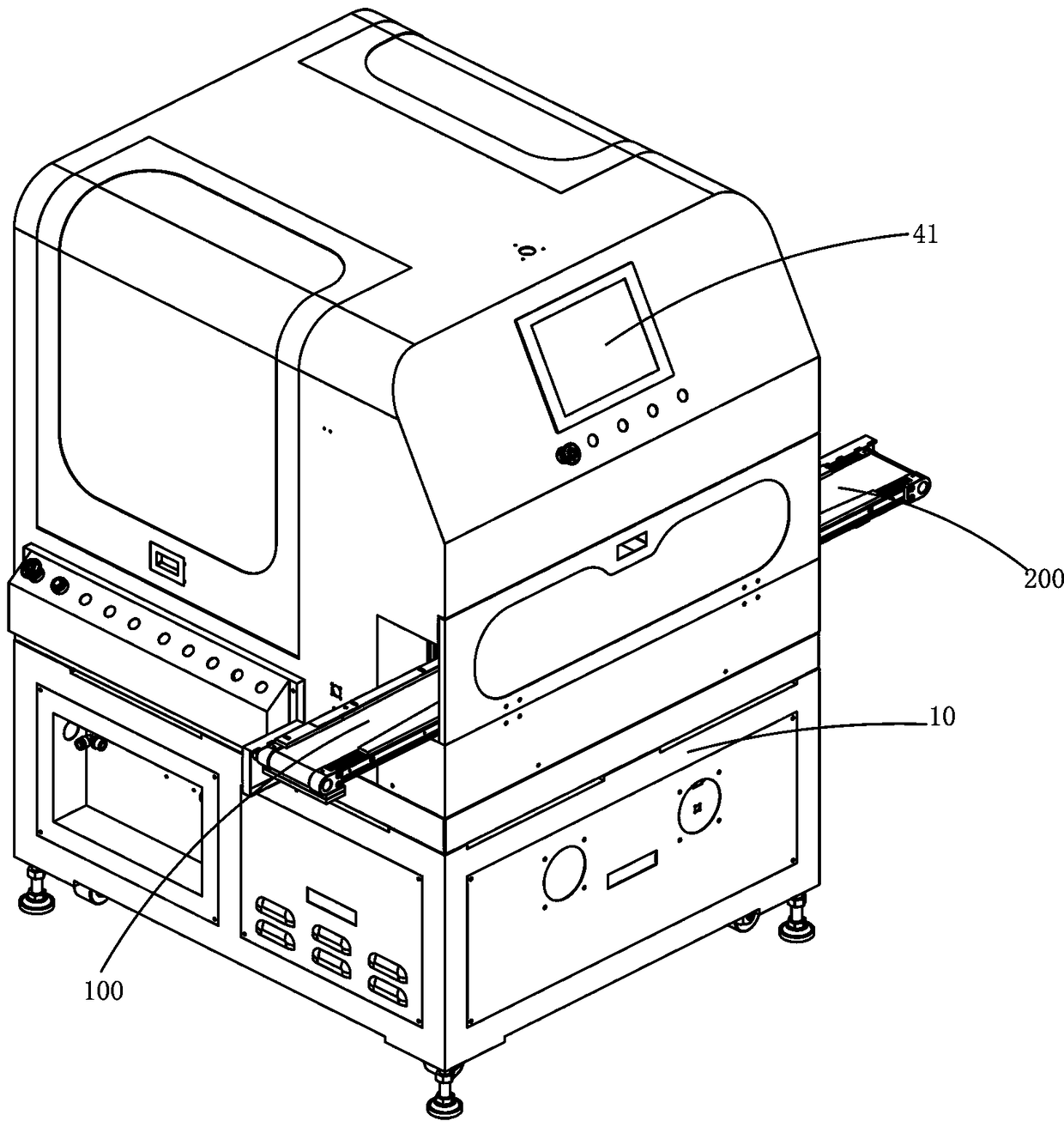

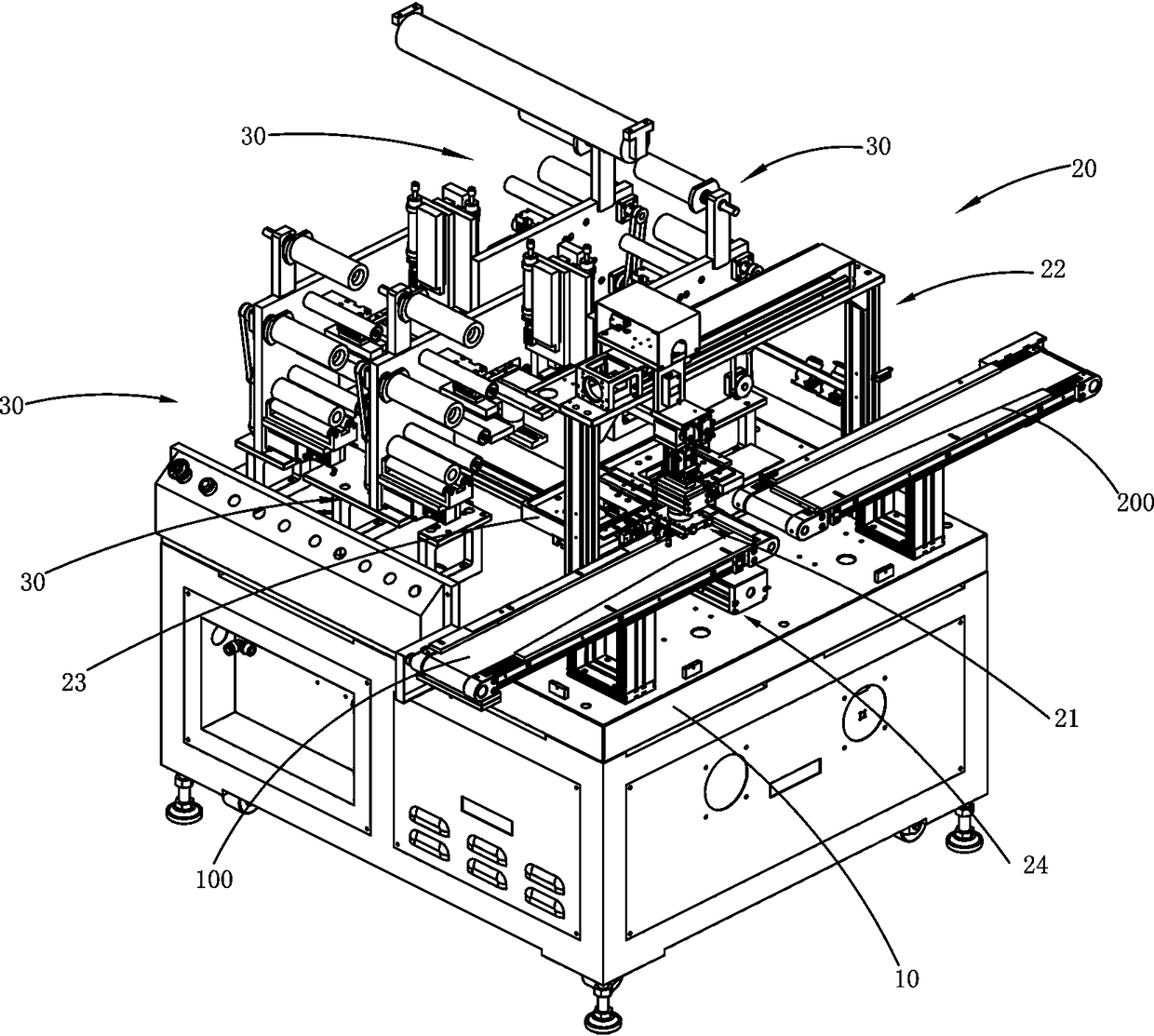

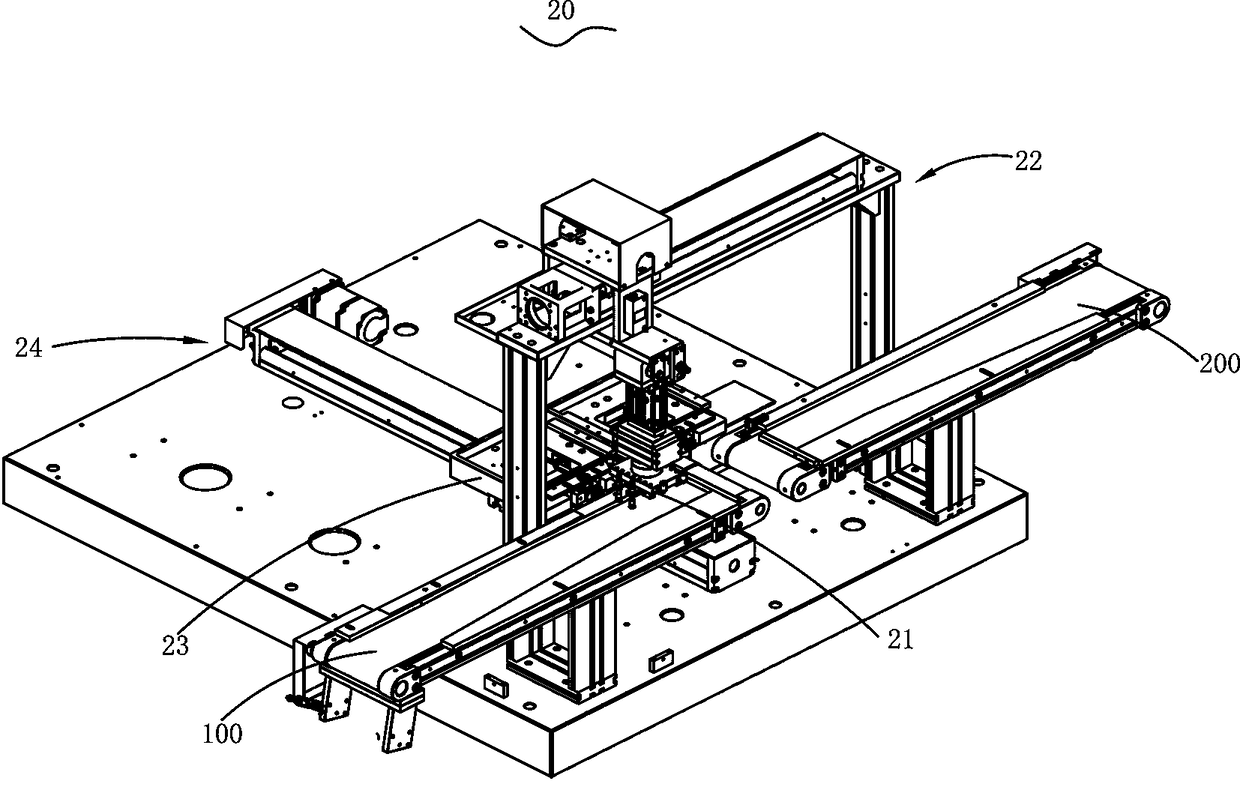

Full-automatic PCB labeling machine and implementation method thereof

The invention relates to the field of labeling equipment and in particular relates to a full-automatic PCB labeling machine and an implementation method thereof. The full-automatic PCB labeling machine comprises a frame, wherein a runner mechanism used for conveying PCBs is arranged in the frame; a label supply mechanism used for supplying label strips and stripping to-be-attached labels in the label strips is arranged at a position, which is positioned on the runner mechanism, in the frame; a labeling manipulator mechanism used for transferring and attaching the to-be-attached labels to the corresponding positions on the PCB is arranged at a position, which is positioned at the output end of the label supply mechanism, on the runner mechanism; and a labeling induction camera used for identifying position information of the to-be-attached labels of the PCB and label information is arranged on the labeling manipulator mechanism. According to the labeling machine disclosed by the invention, the on-line synchronization between production site information and an internal or external system information network can be realized by virtue of a network communication module in a control cabinet, the labels are attached to the surfaces of the PCBs or components with different angles, the labeling application range is wide, and the universality is high; and moreover, different materials can be adhered, the integration is high, the automation is high, the manual operation is not required, and the labeling sequence, labeling strength and frequency can be changed according to needs.

Owner:SHENZHEN BORWIN PRECISION MACHINERY

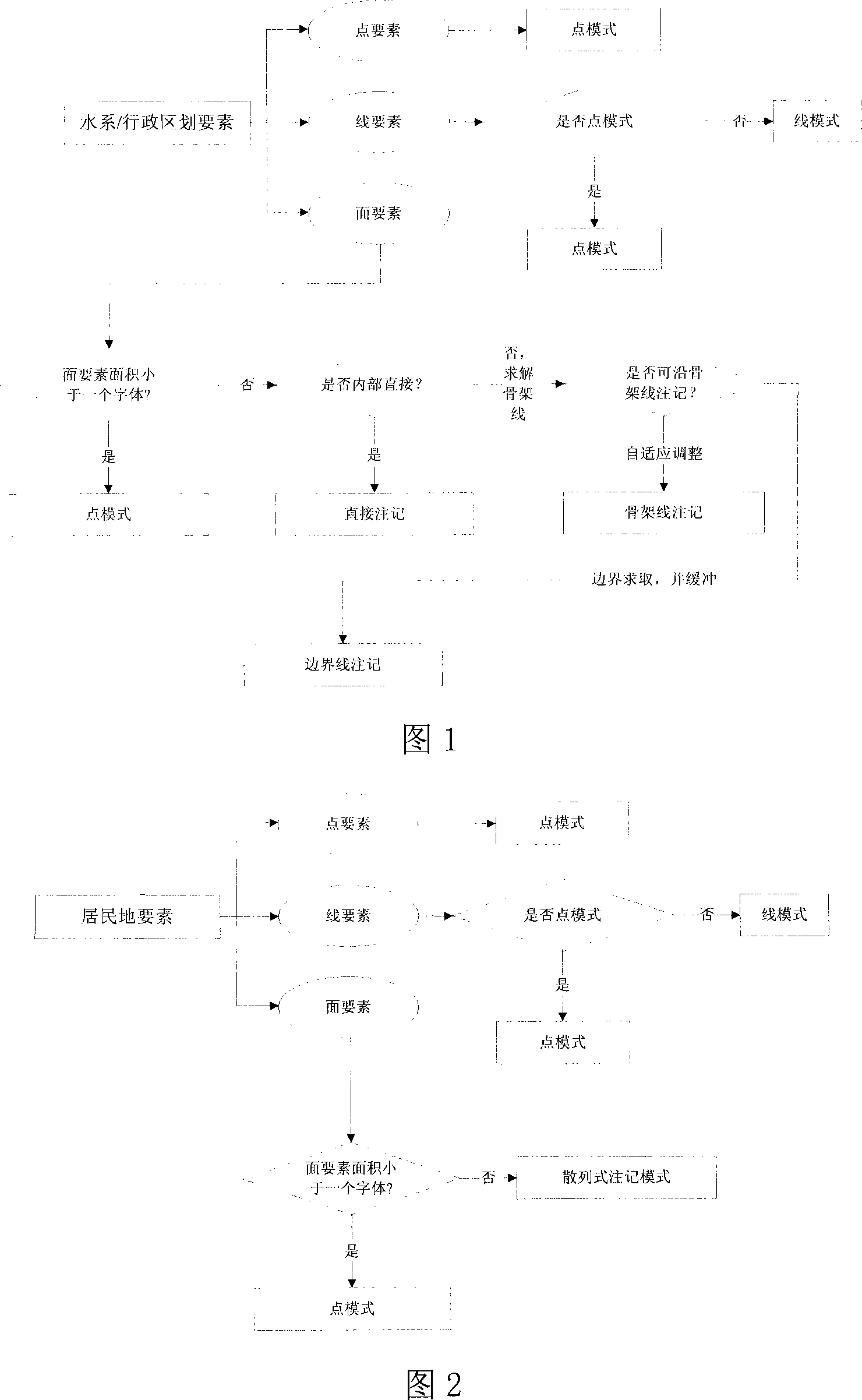

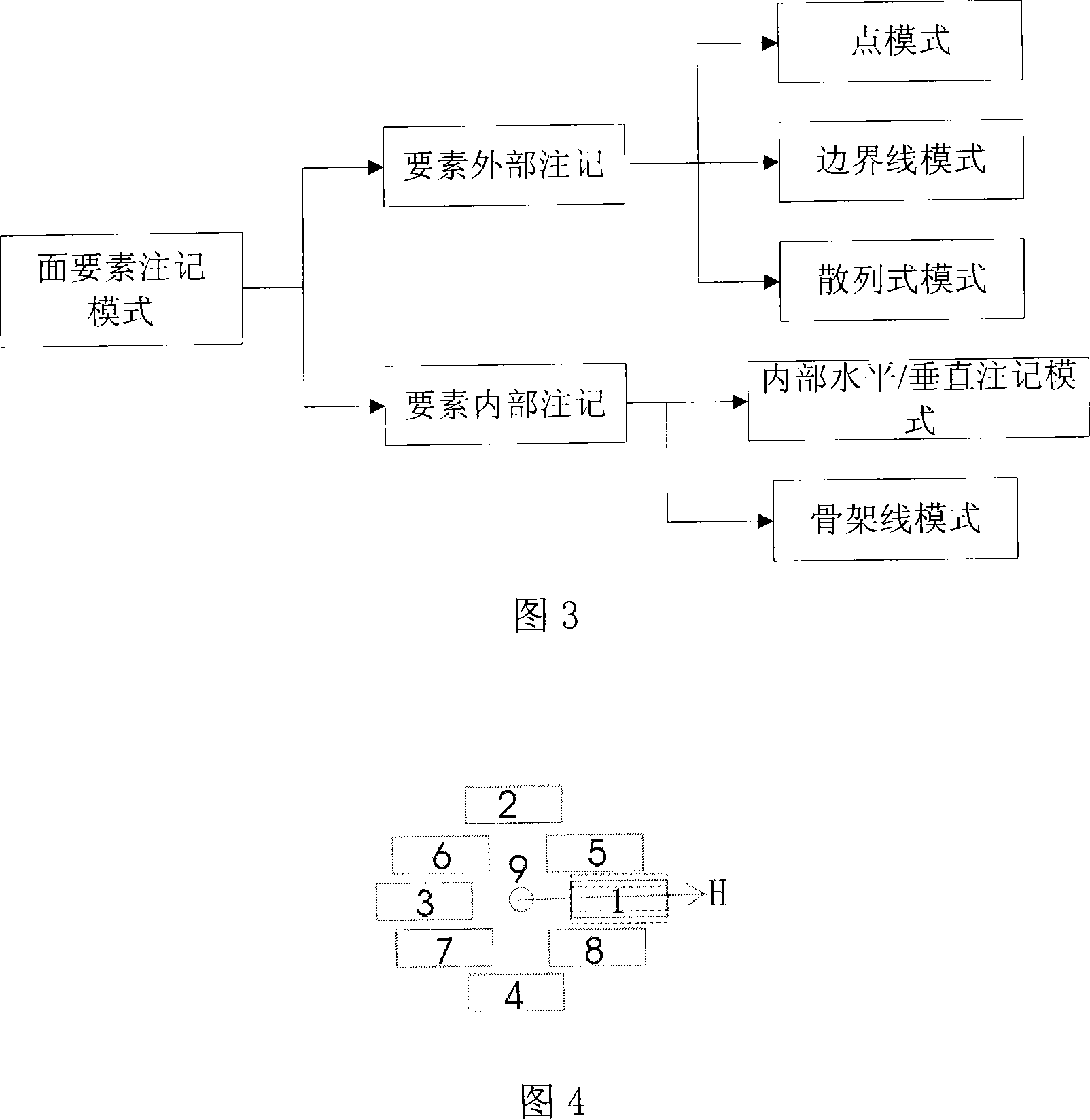

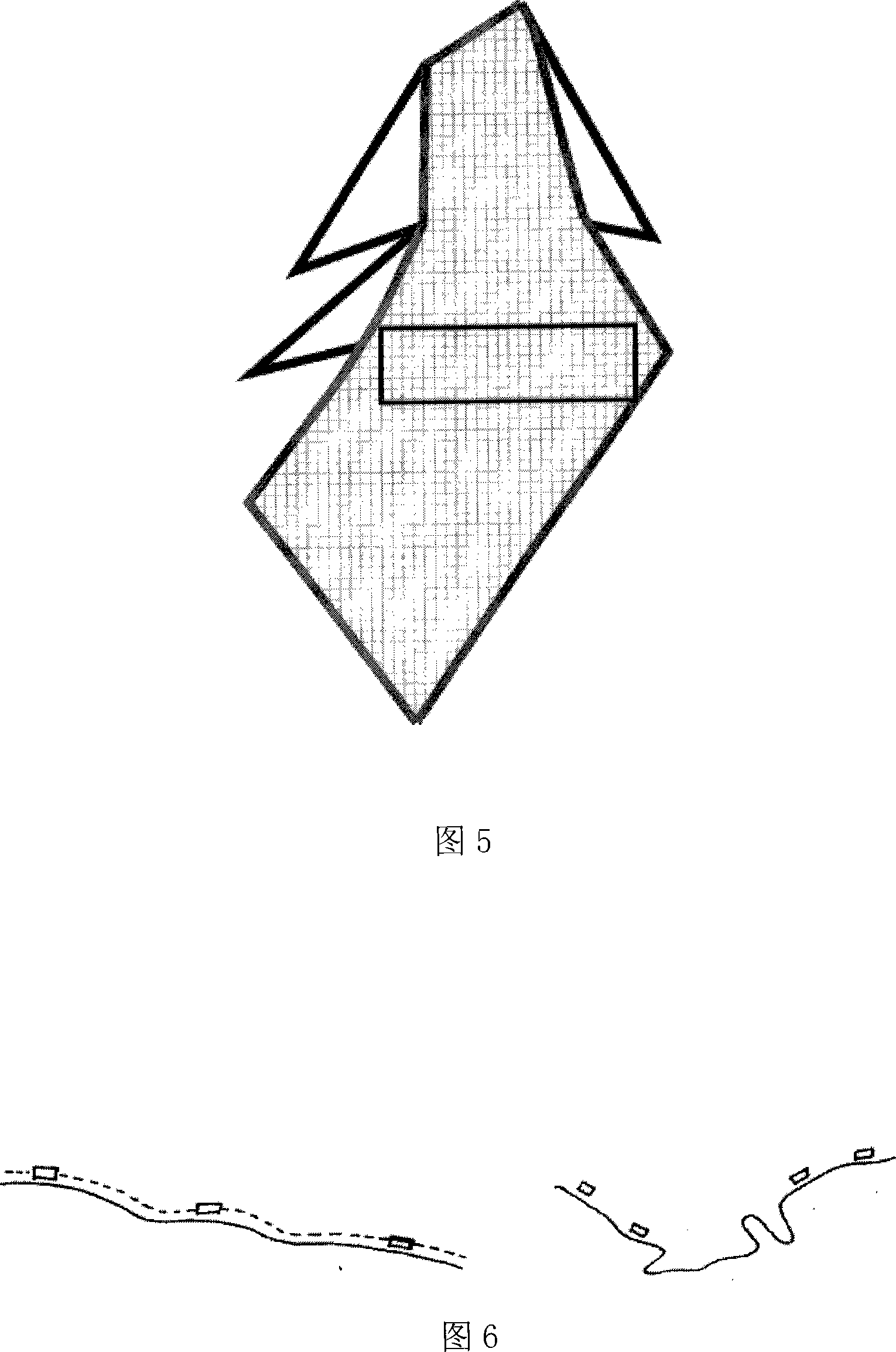

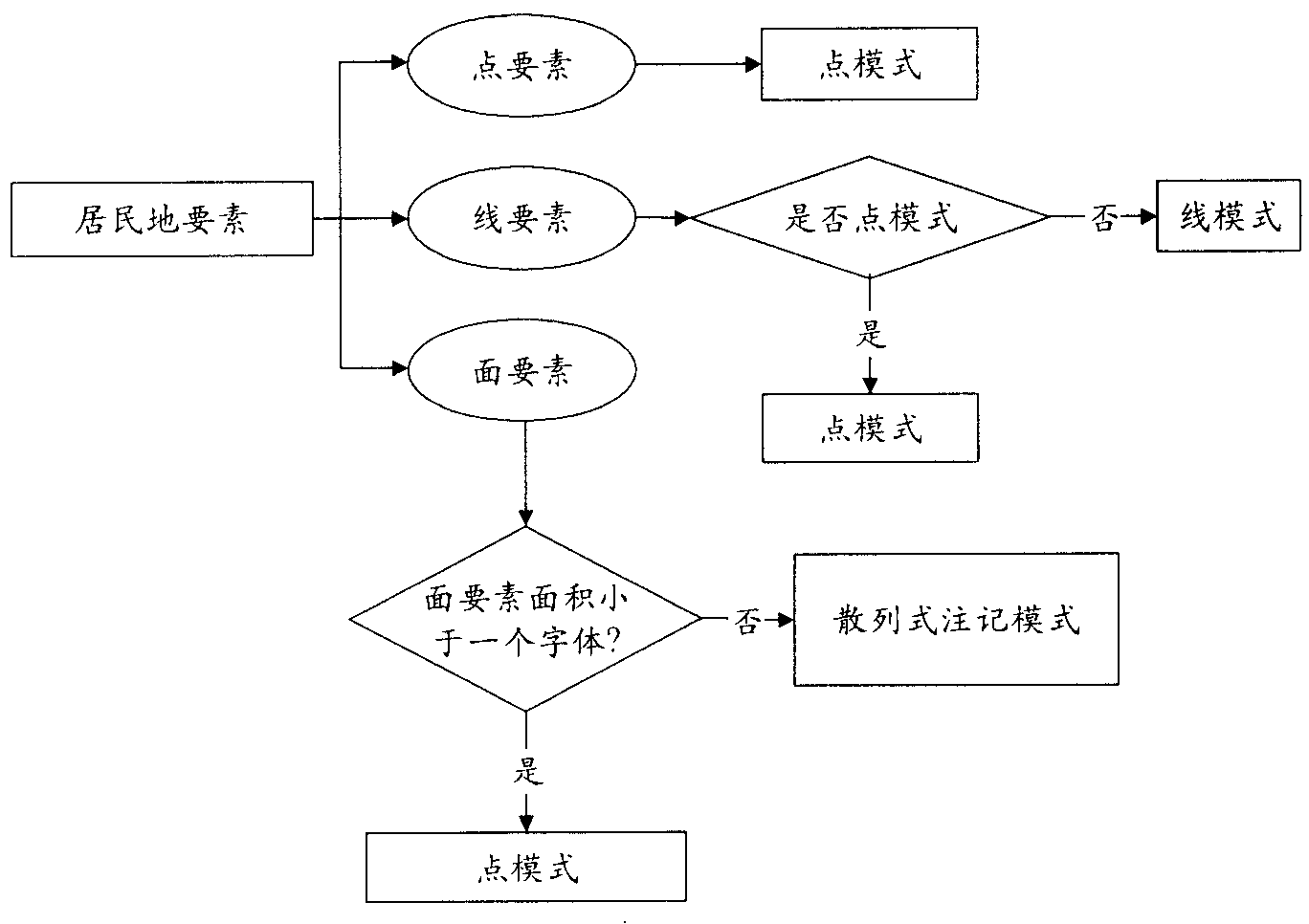

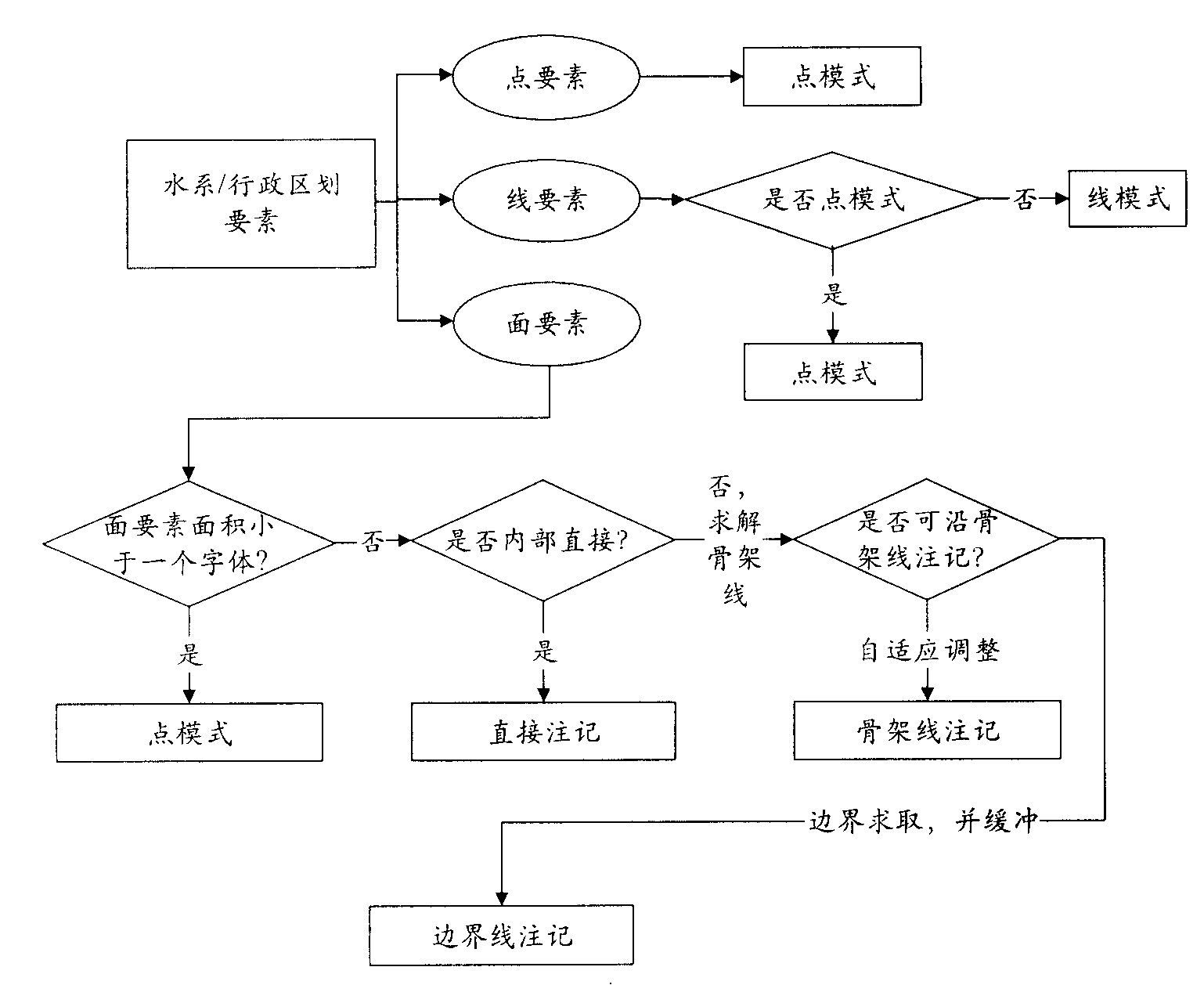

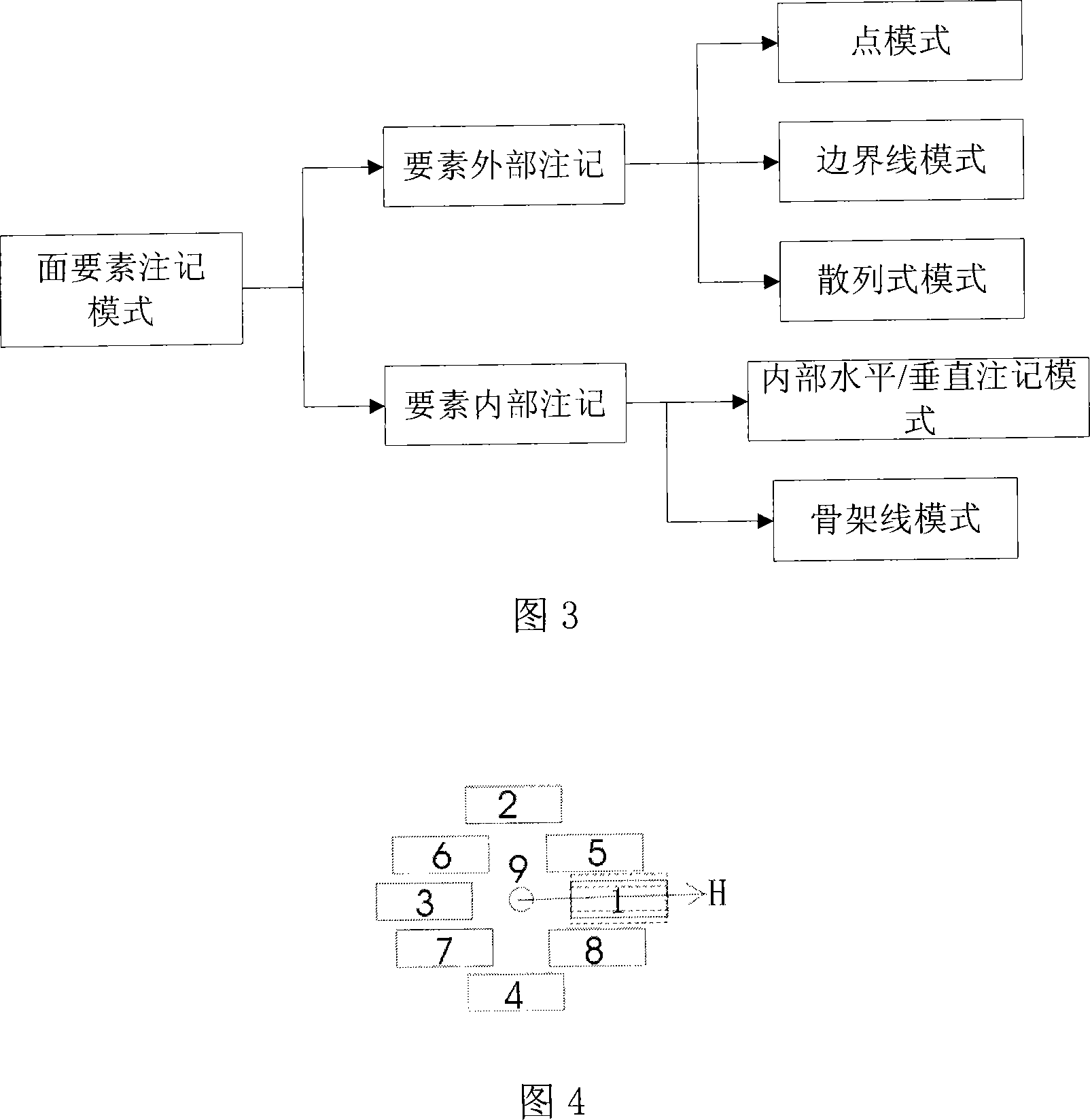

Face-shaped element configuring method in computer graphics

InactiveCN101183461AImprove the efficiency of automatic annotationSolve the problem of intelligent configurationMaps/plans/chartsSpecial data processing applicationsComputerized systemTopographic map

The invention relates to a configuration method for area pattern in computer drawing, belonging to the technical field of computer drawing, which comprises the following steps: step one, importing the geography data into the computer and then judging the pattern type waiting for noting in the geography data; step two, deciding the noting mode type of the noting pattern according to the pattern type; step three, configuring the pattern waiting for noting according to the configuration rule of the noting mode type. The invention divides the noting configuration of the area pattern into five basic modes according to the substantive characteristics and the configuration rules of the patterns of the water system and settlement place, provides the automatic configuration arithmetic of noting of different modes according to the geometrical characteristics of the modes, and resolves the problems of collision or shelter of the different noting modes in topographic maps with full elements. The invention has the advantages of improved efficiency of automatically noting the area pattern and enhanced noting quality of the map.

Owner:常熟紫金知识产权服务有限公司

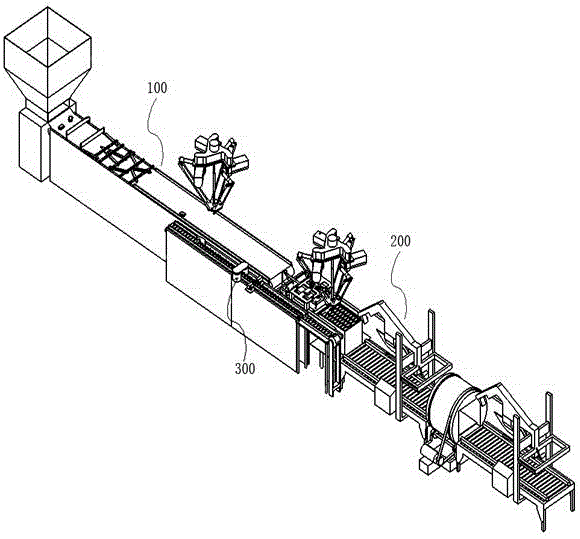

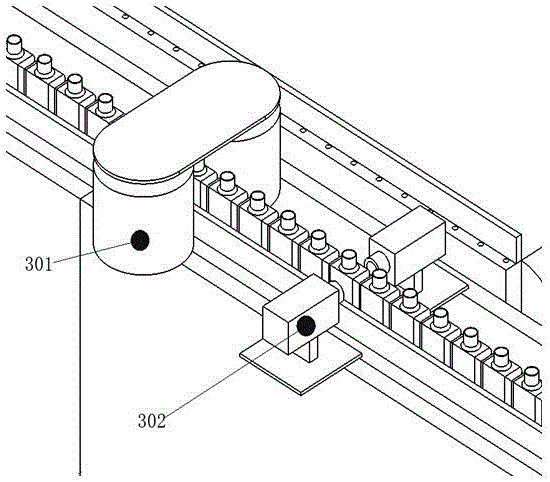

High-speed damage-free bottle-arranging, labeling, detecting and packaging production line

ActiveCN105883366AHigh degree of mechanizationAchieve protectionConveyorsWrapping material feeding apparatusProduction lineManipulator

The invention discloses a high-speed damage-free bottle-arranging, labeling, detecting and packaging production line which comprises a bottle arranging assembly used for arranging plastic bottles, a labeling and label detection assembly used for labeling and detecting the plastic bottles, and a boxing assembly used for filling the box, wherein the bottle arranging assembly comprises a stock bin, a front layered column, a rear layered column, a sorting rod assembly and a manipulator which are sequentially arranged in the production direction; the boxing assembly comprises a film spreading mechanism, a top box mechanism, a front box sealing machine, a turning machine and a rear box sealing machine which are sequentially arranged in the production direction; the production line also comprises a conveyor belt used for conveying the plastic bottles to a to-be-boxed area; the boxing assembly is arranged on the side face of an arc-shaped vertical bottle conveyor belt of the bottle arranging assembly; and the labeling and label detection assembly comprises a labeling mechanism which is arranged on the arc-shaped vertical bottle conveyor belt and is in a vertical state and a label detection mechanism used for detecting the labeling quality.

Owner:LOOBI GUANGZHOU HEALTH IND CO LTD +1

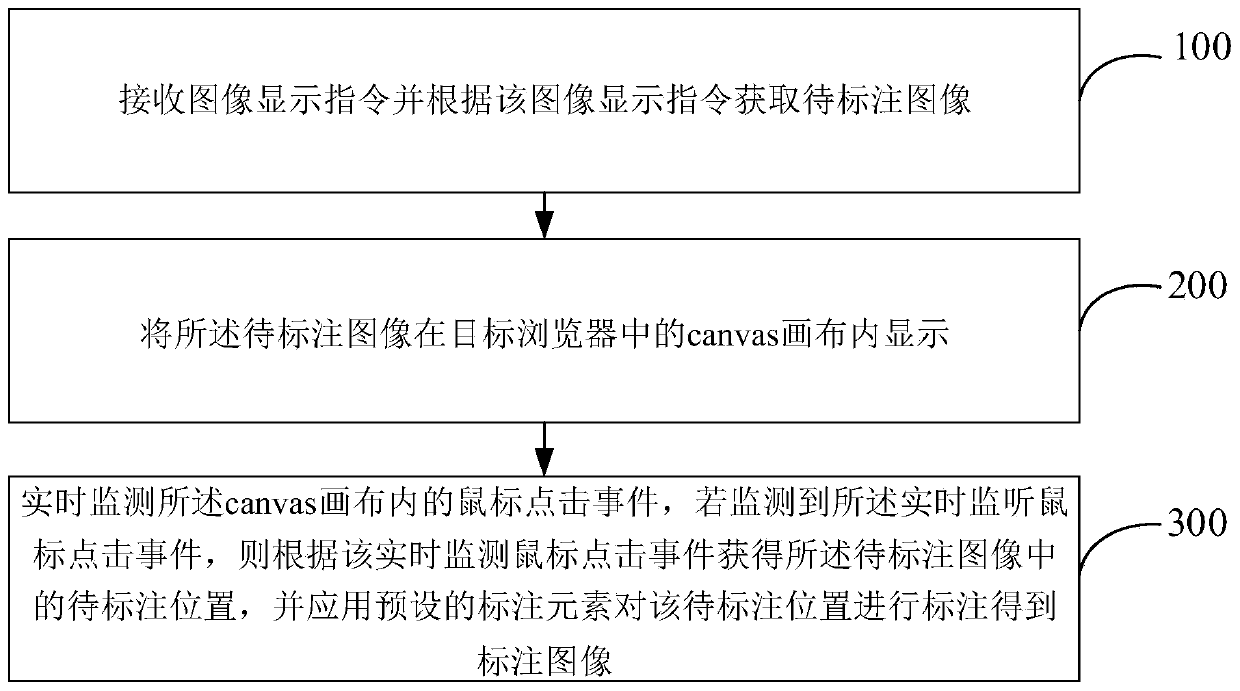

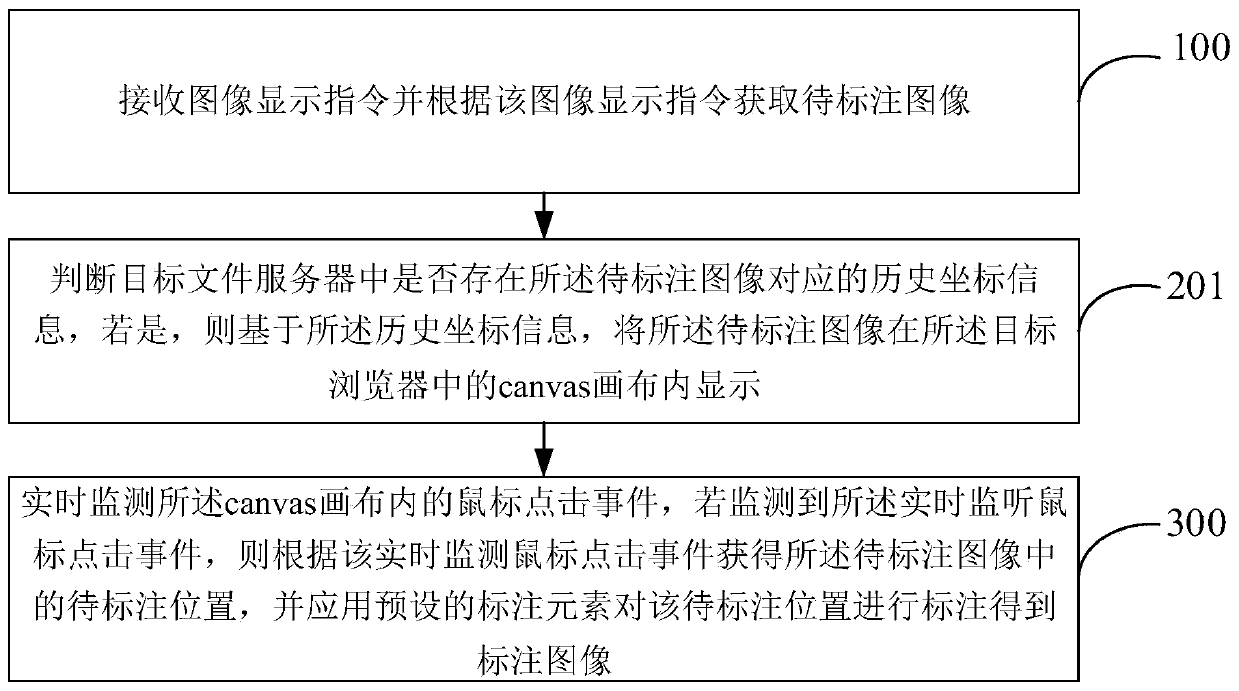

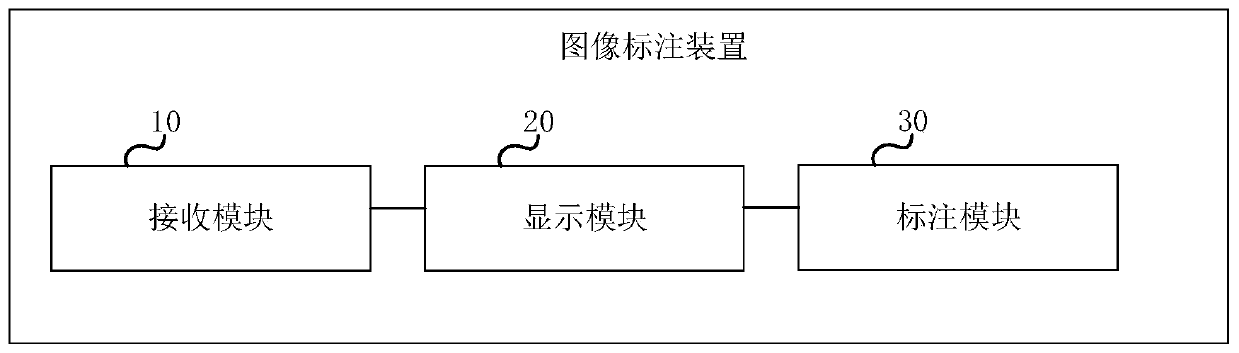

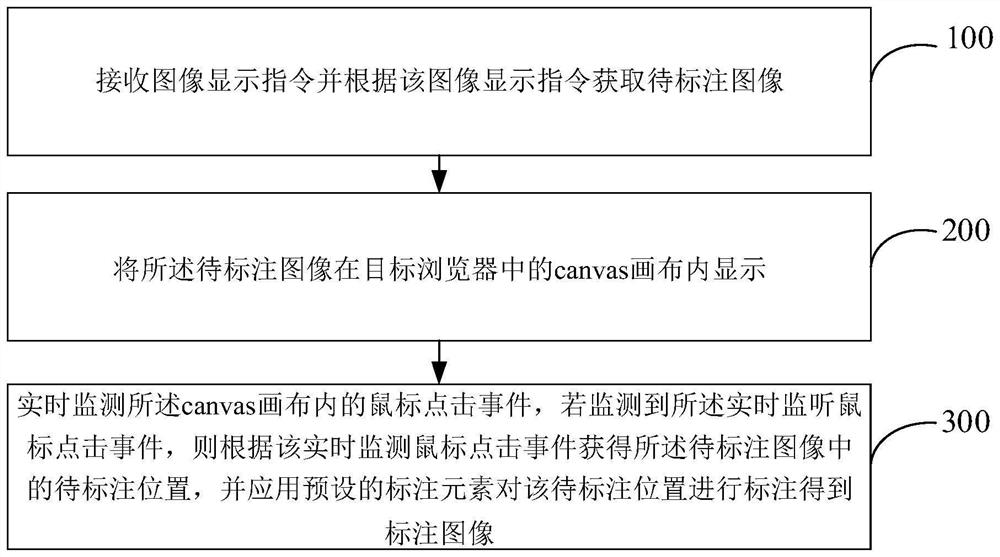

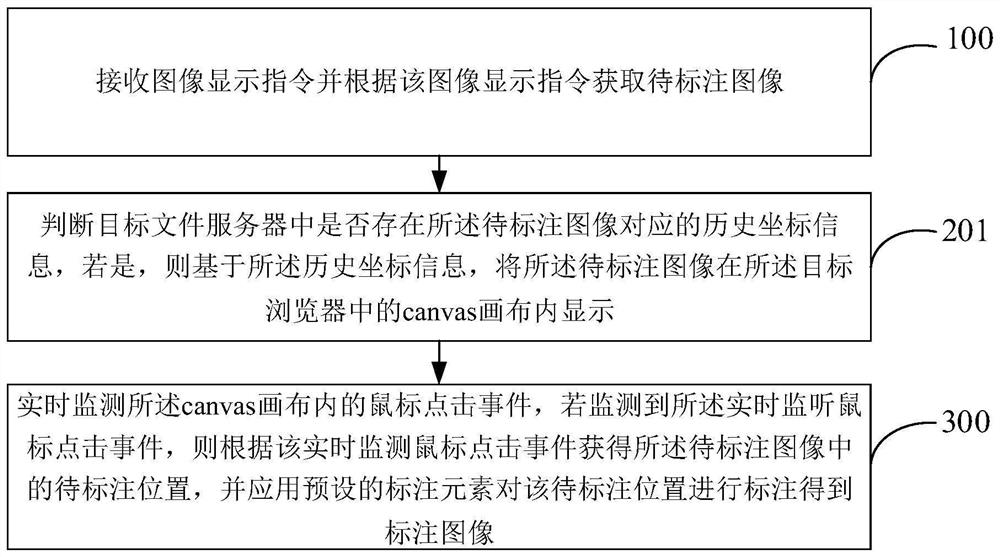

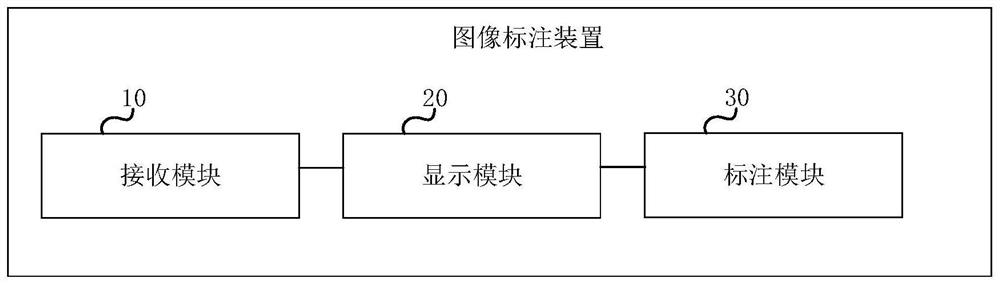

Image labeling method and device

ActiveCN111367445AImprove annotation qualityImprove labeling efficiencyInput/output processes for data processingRadiologyImage detection

The invention provides an image annotation method and device, and the method comprises the steps: receiving an image display instruction, and obtaining a to-be-annotated image according to the image display instruction; displaying the image to be labeled in a canvas in a target browser; and monitoring a mouse click event in the canvas in real time, if the mouse click event is monitored in real time, obtaining a to-be-annotated position in the to-be-annotated image according to the mouse click event monitored in real time, and annotating the to-be-annotated position by applying a preset annotation element to obtain an annotated image. The image annotation quality and efficiency can be improved, and then the accuracy and efficiency of transaction certificate image classification or intelligent driving image detection achieved by applying the image annotation result can be improved.

Owner:CHINA CONSTRUCTION BANK

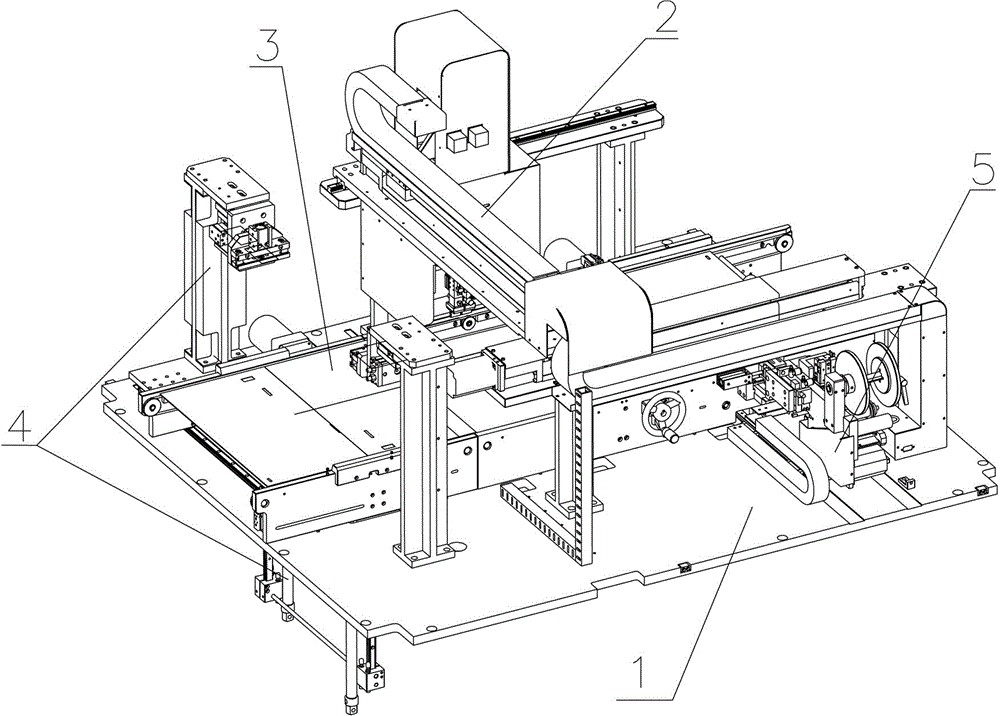

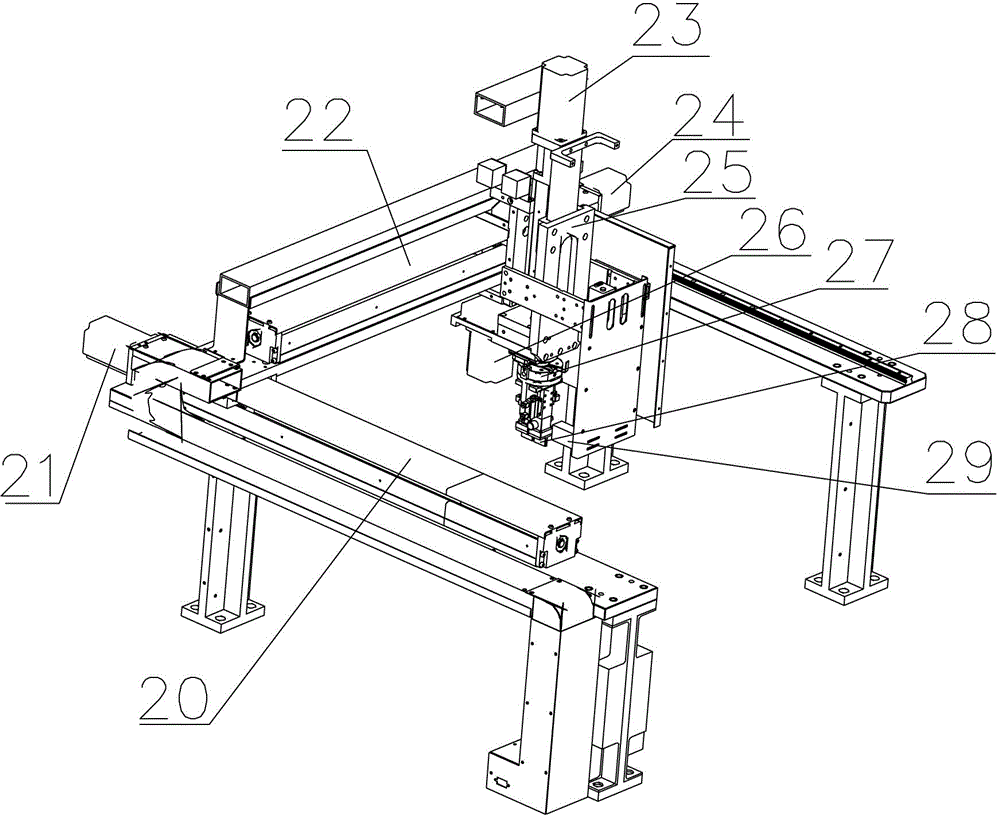

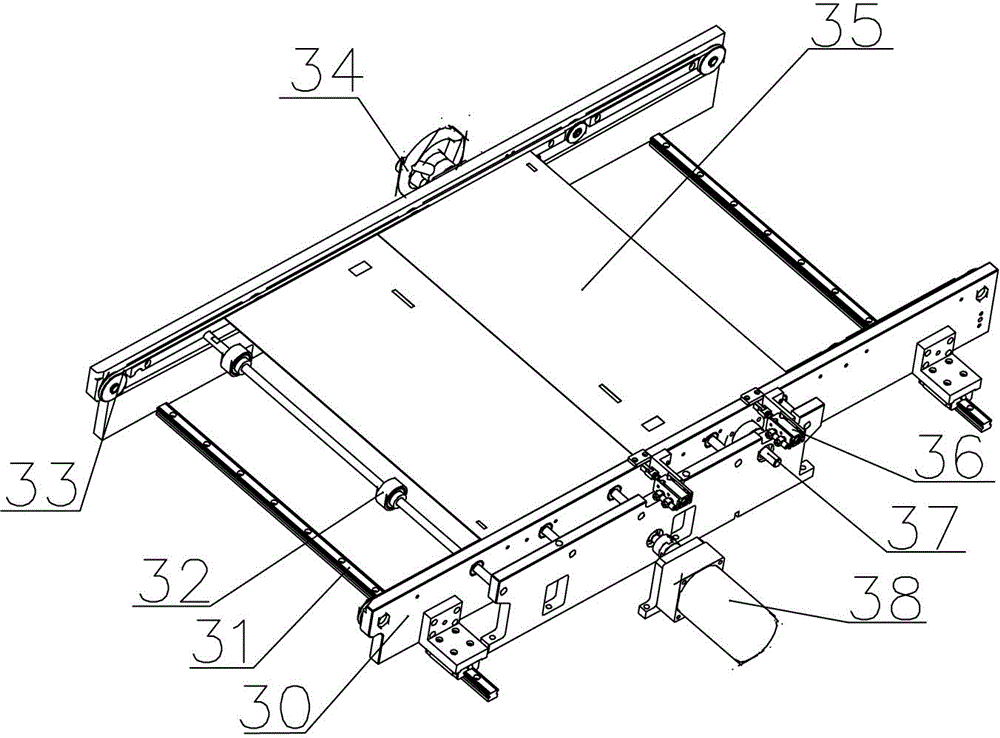

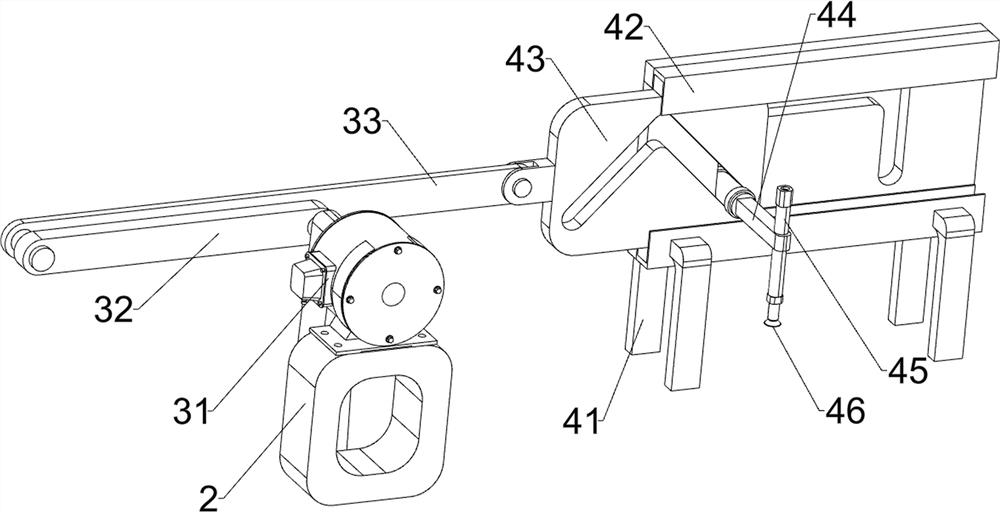

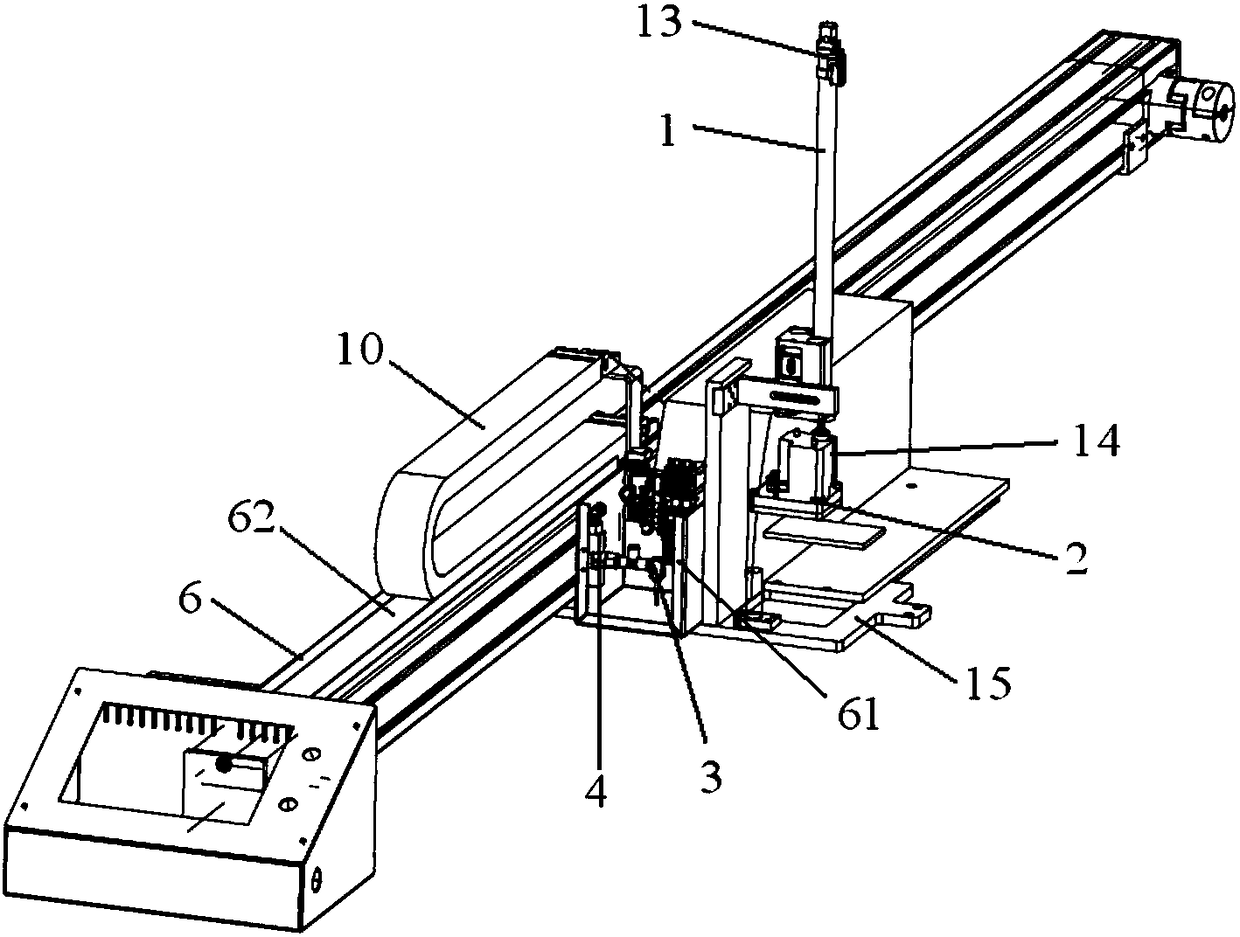

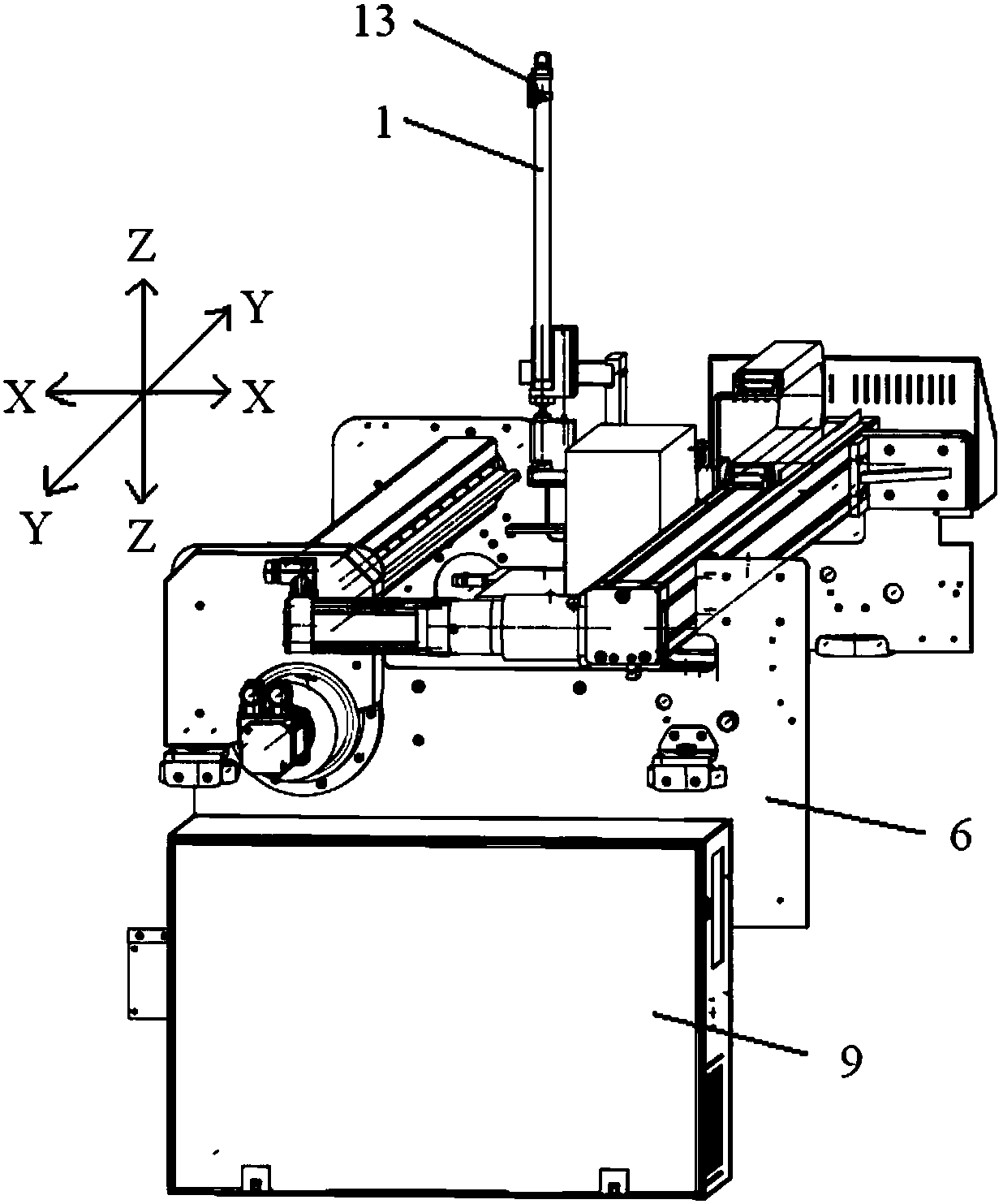

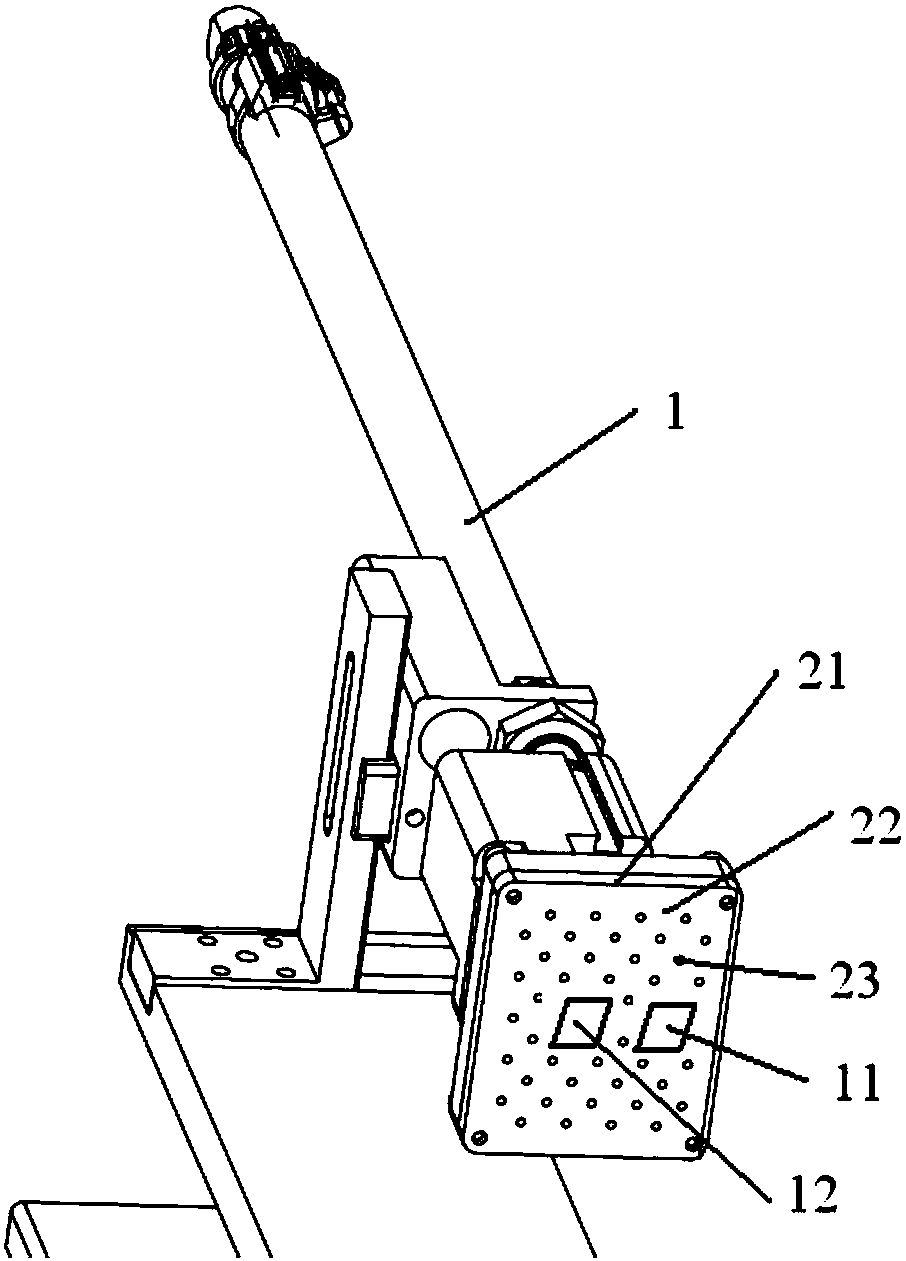

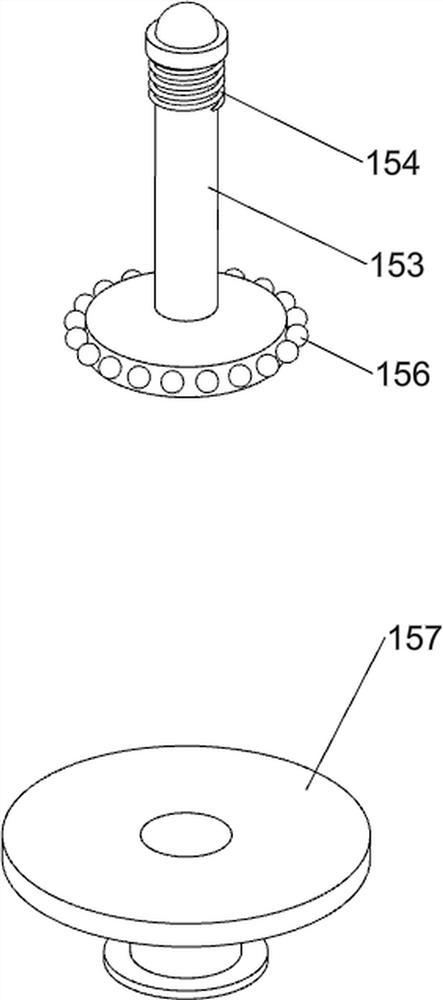

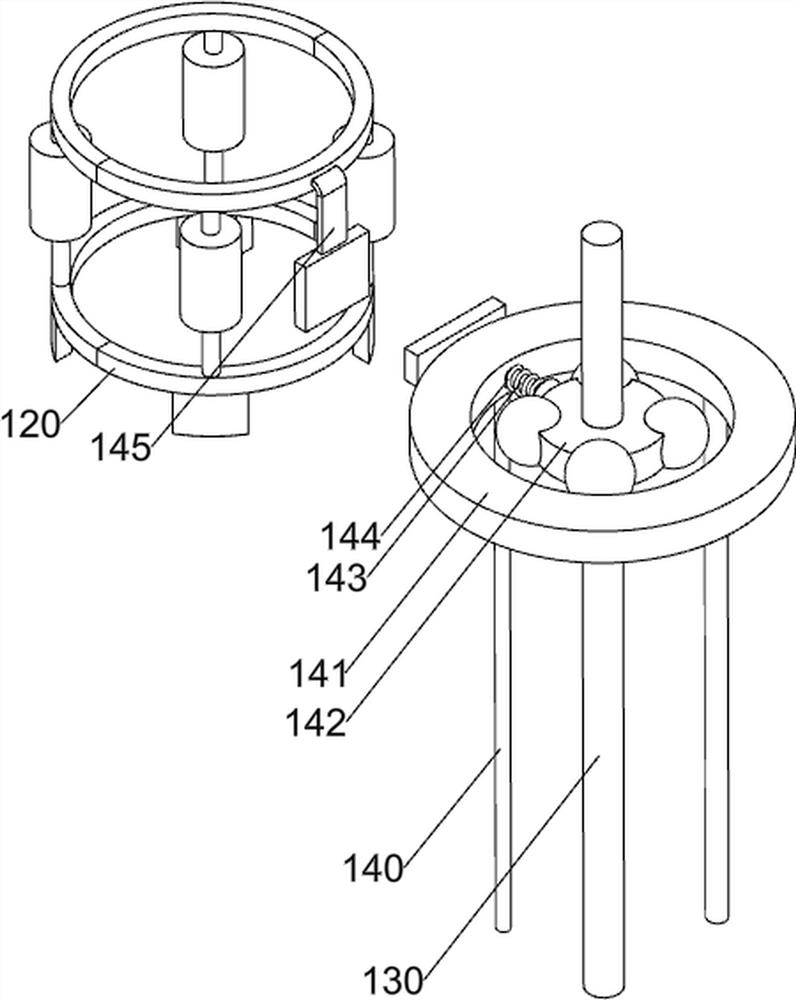

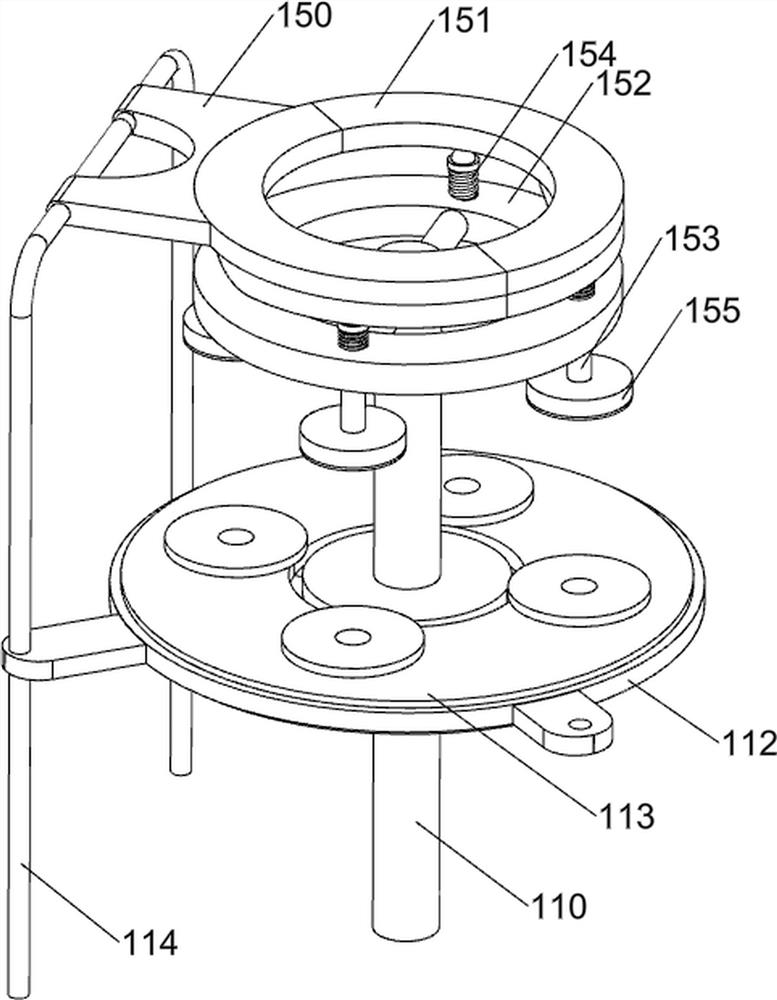

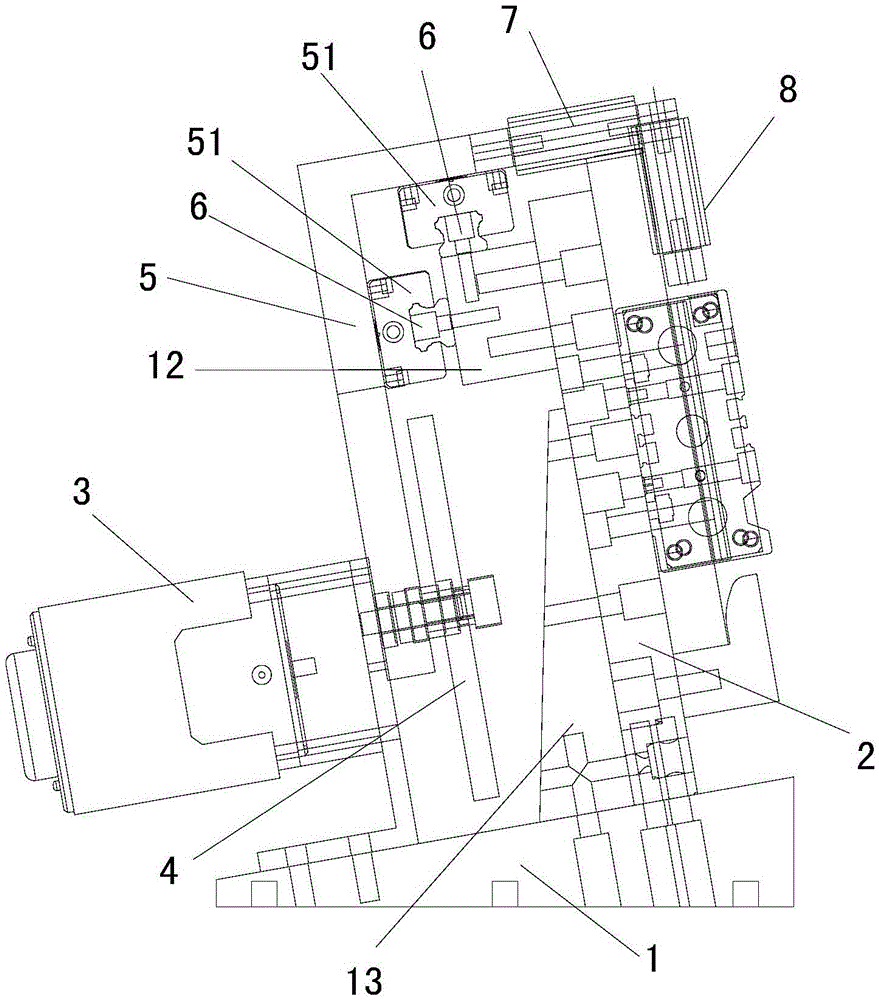

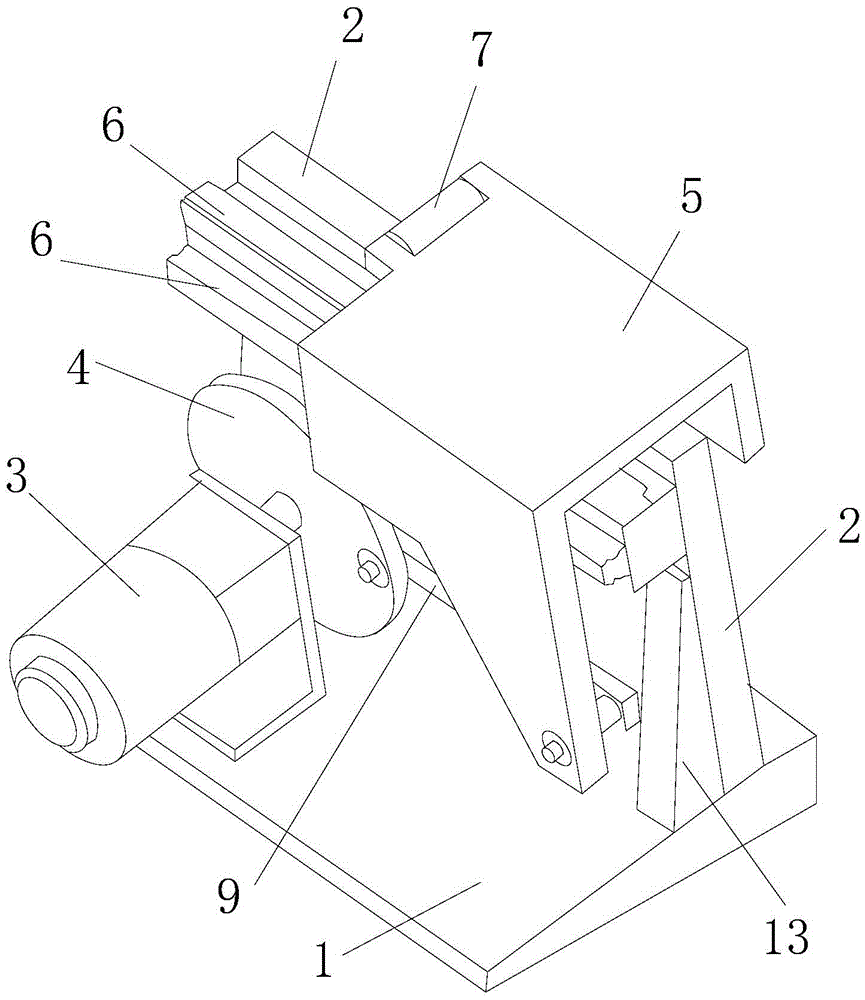

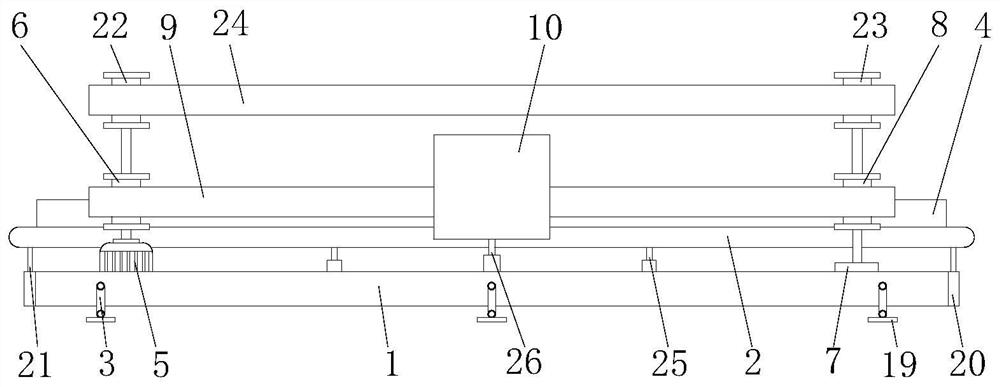

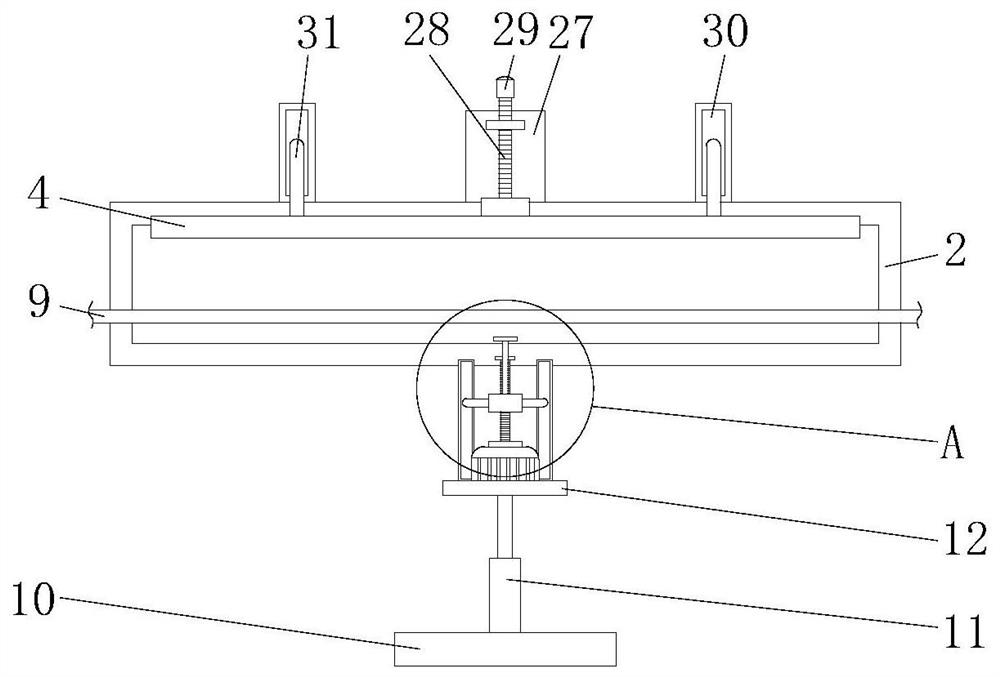

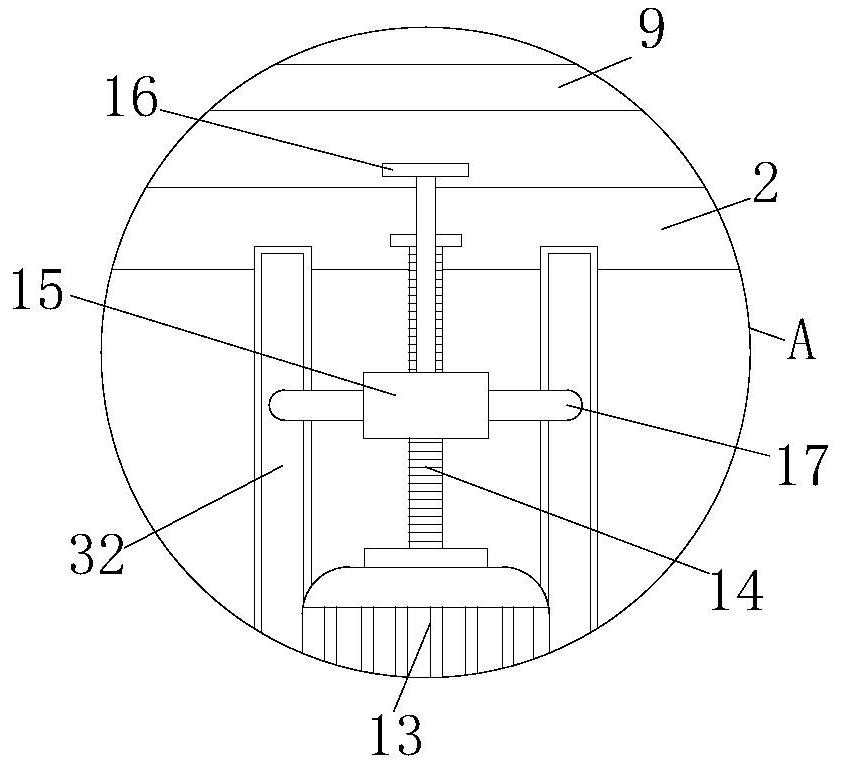

Automatic labeling machine

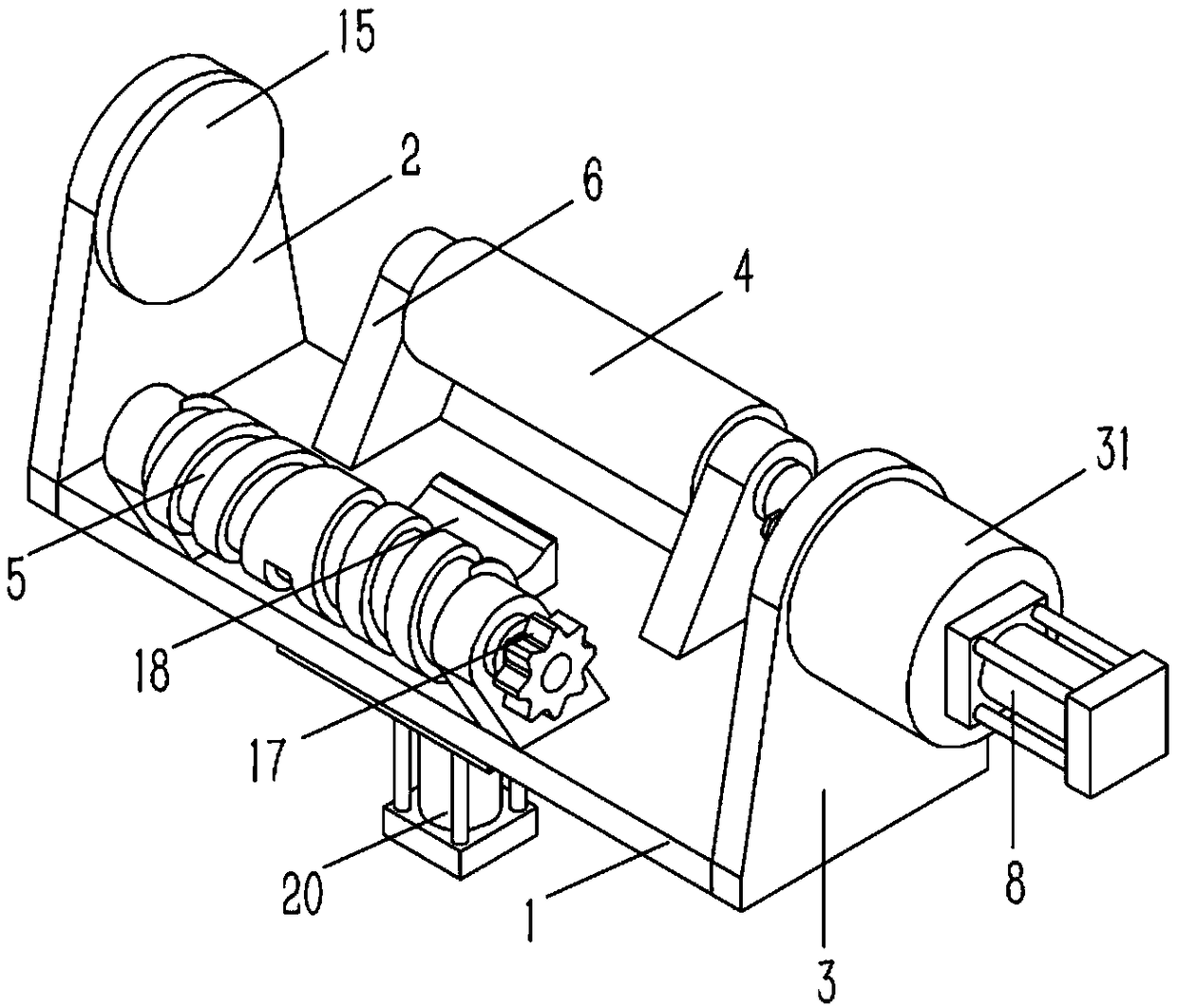

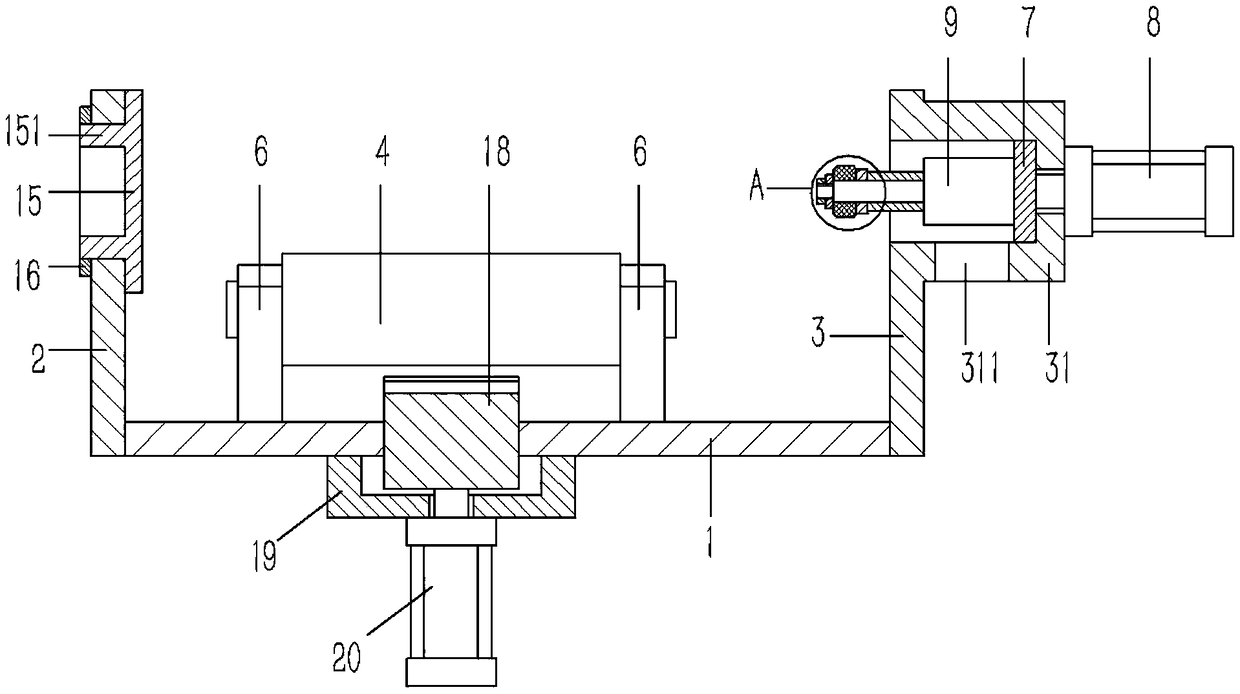

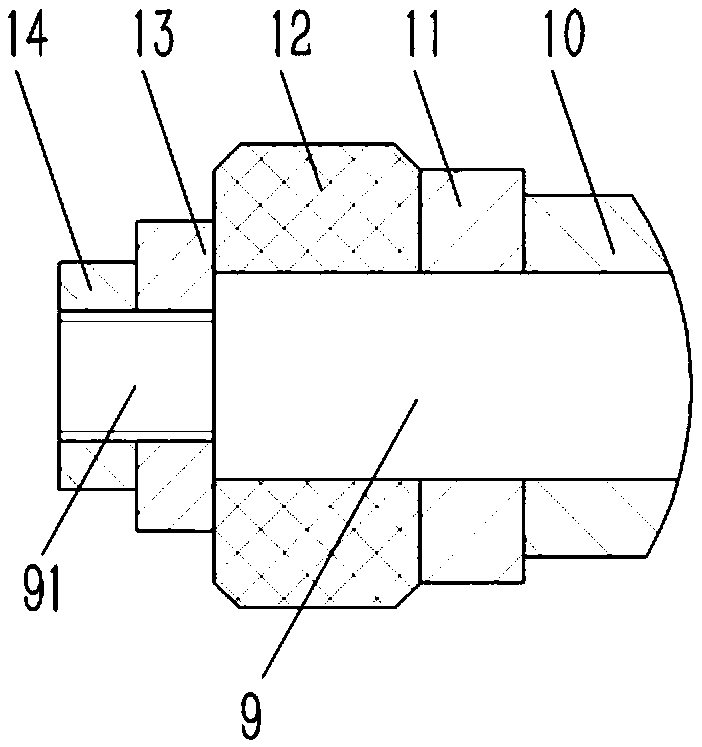

InactiveCN108163310AImprove work efficiencyGuaranteed labeling qualityLabelling machinesReciprocating motionEngineering

The invention discloses an automatic labeling machine. The automatic labeling machine comprises a conveying belt and a label sucking and labeling mechanism. A labeling station is prearranged on the motion path of the conveying belt. The label sucking and labeling mechanism comprises an X-direction moving mechanism, a Y-direction moving mechanism, a Z-direction moving mechanism, a rotary mechanismand a vacuum suction cup. The X-direction moving mechanism, the Y-direction moving mechanism and the Z-direction moving mechanism are used for achieving reciprocal rectilinear motion of the vacuum suction cup in the X direction, the Y direction and the Z direction. The rotary mechanism is used for achieving rotation of the vacuum suction cup. Under the action of cooperation of all the moving mechanisms, the vacuum suction cup reciprocates between the labeling station and a prearranged label sucking station; when the vacuum suction cup moves to the label sucking station, the vacuum suction cuprotates to face electronic labels and completes label sucking operation; and when the vacuum suction cup moves to the labeling station, the vacuum suction cup rotates to face products and completes labeling operation. By applying the automatic labeling machine, all the products can be labeled automatically, the working efficiency can be greatly improved, the labeling quality can be ensured, and the labor cost is lowered.

Owner:DONGGUAN HUABEL ELECTRONICS TECH

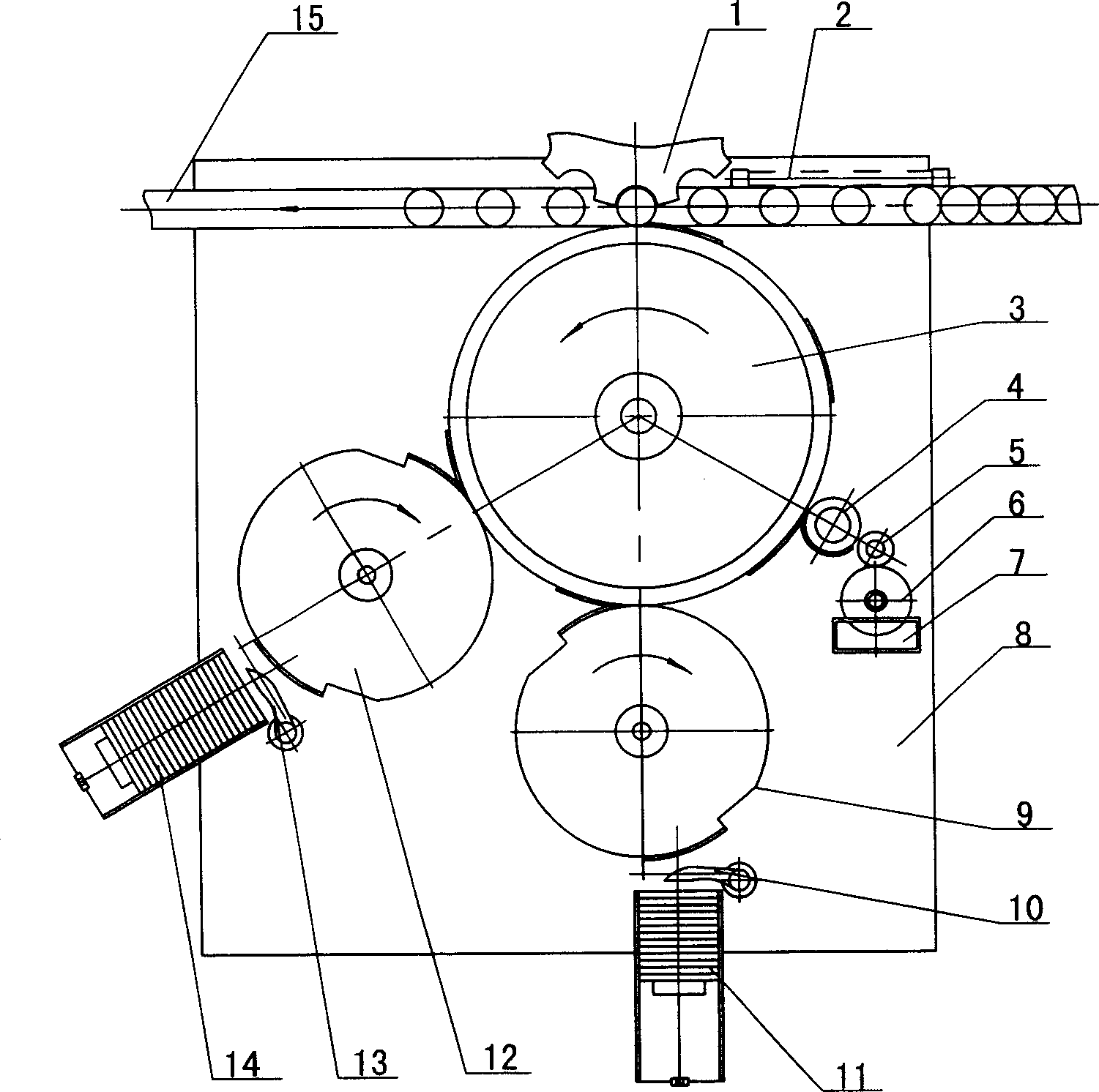

Double tag-suction high speed tag-pasting machine

InactiveCN1865087AReduce the number of drawsReduce frequencyLabelling machinesLabelling short rigid containersEngineeringBottle

The invention relates to a dual-adhesive-label high-speed label machine, which is used to stick label on the drug bottle. Wherein, it comprises a rotation drum, an adsorption drum, a paste wheel, a drug bottle transfer band and a bottle dial disk; the transfer band and bottle dial disk are matched with the circumference of rotation drum; the adsorption drum is relative to the rotation drum; one side of adsorption drum is mounted with label box; a label adsorption claw is arranged between the label box and the adsorption drum; the rotation drum is mounted with label compress hook; the descending part of rotation drum is arranged with paste wheel brusher; there are two adsorption drums arranged on the circumference of rotation drum; the rotation drum has two label compress hooks; each adsorption drum has own label box and label adsorption claw; the invention adds adsorption drums based on former label machine, while said two adsorption drums rotate alternatively to supply label; therefore, it can reduce the label adsorption frequency, to confirm the label quality and improve the speed.

Owner:REYOUNG PHARMA

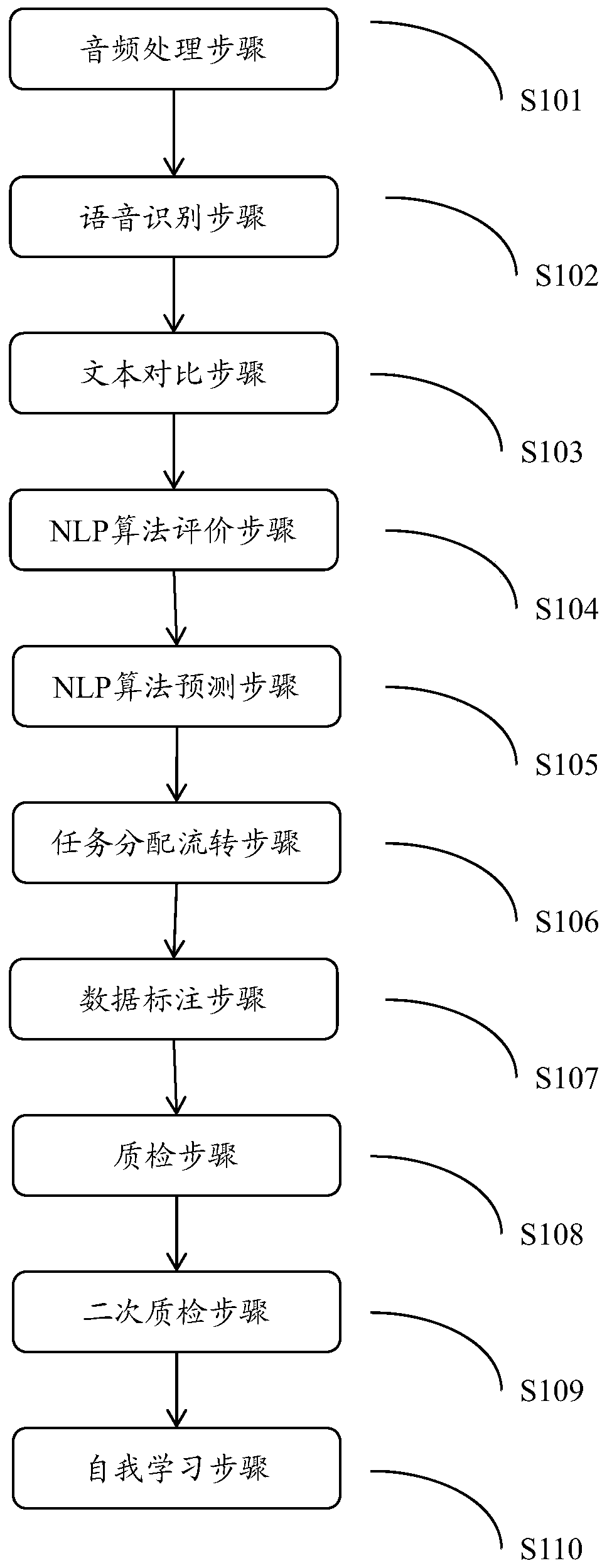

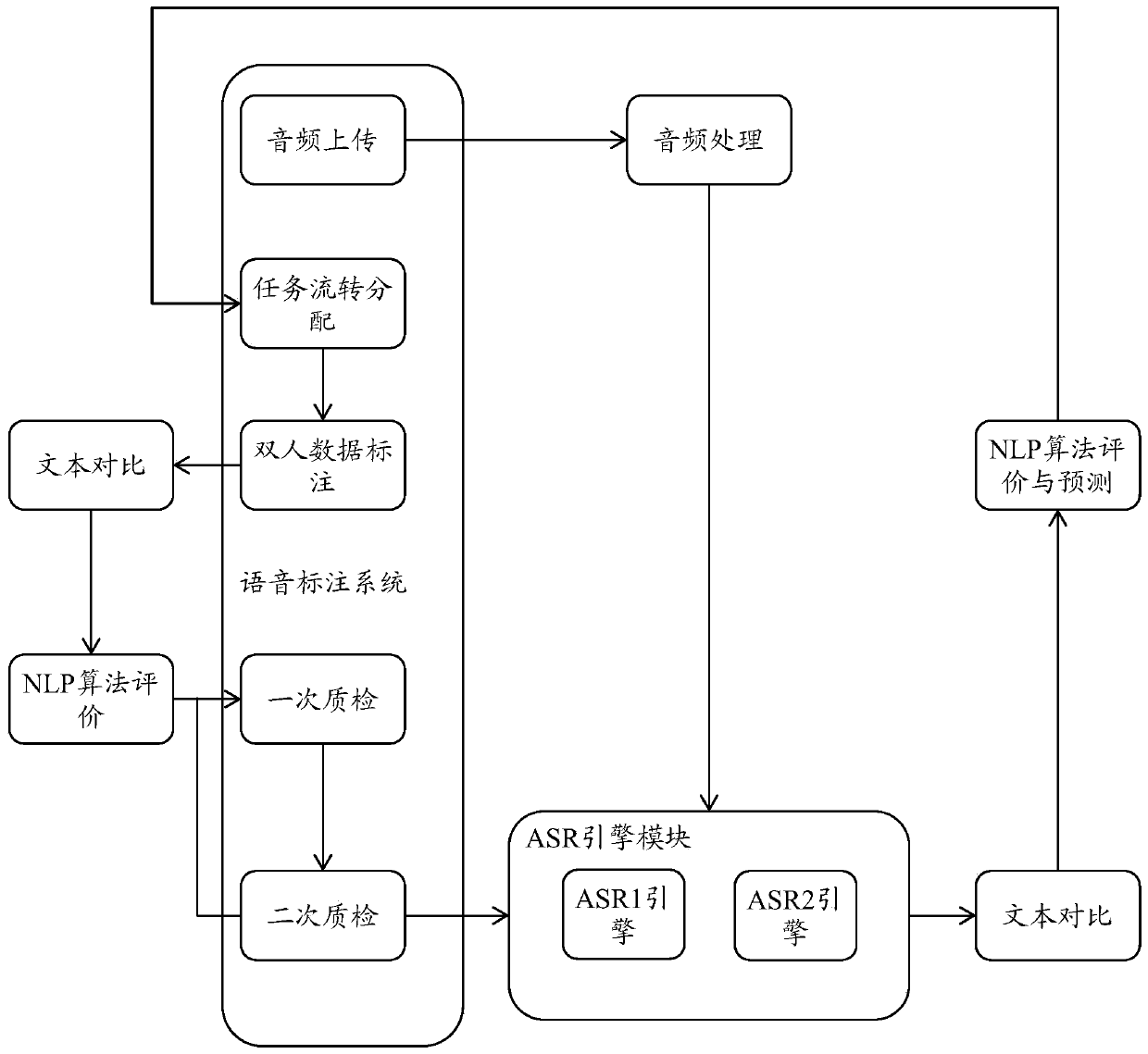

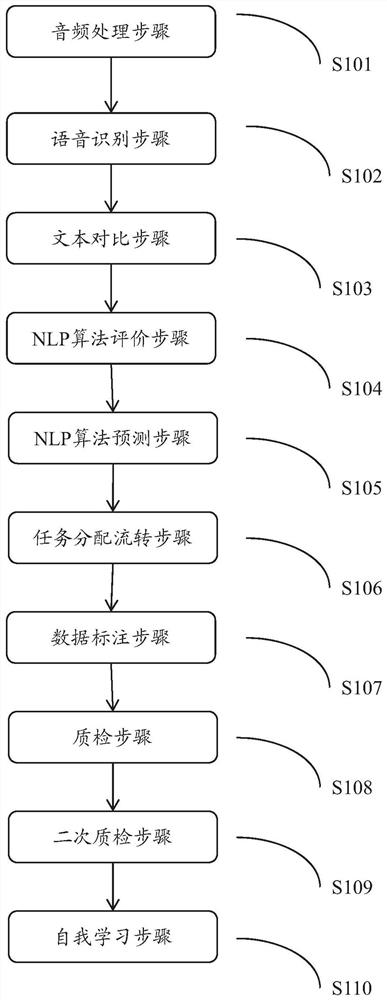

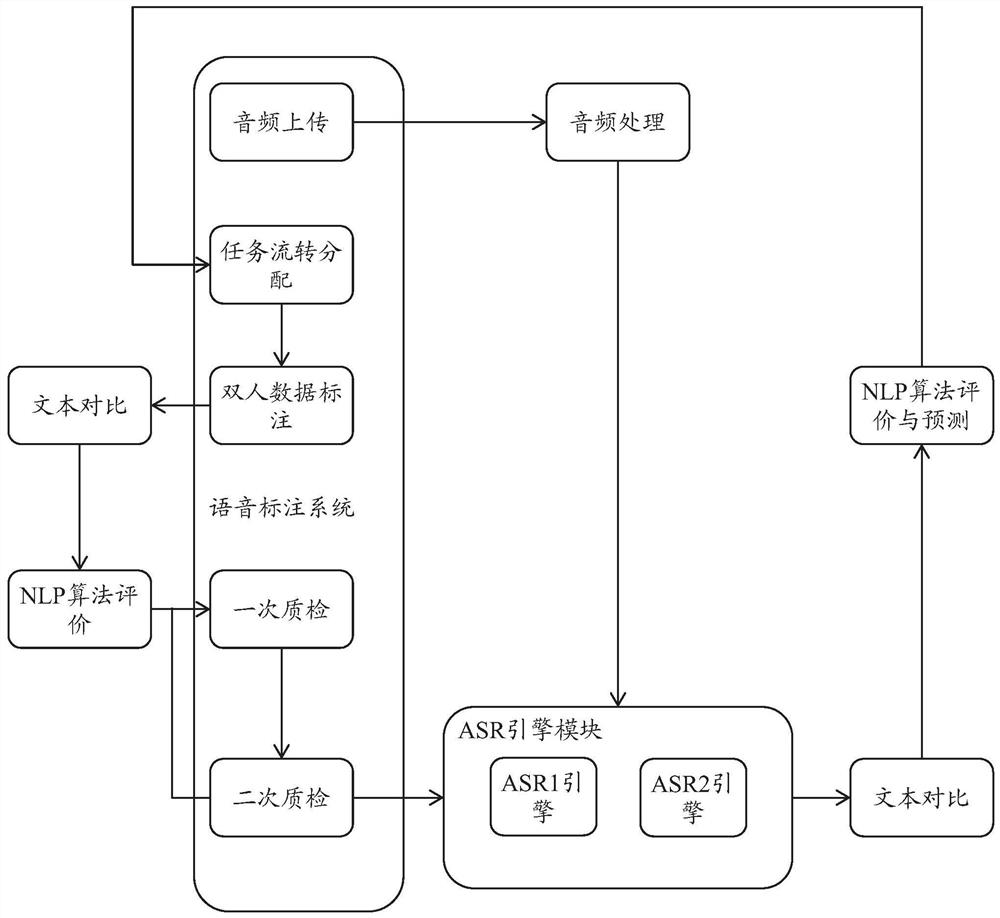

Data labeling method and device based on self-learning algorithm

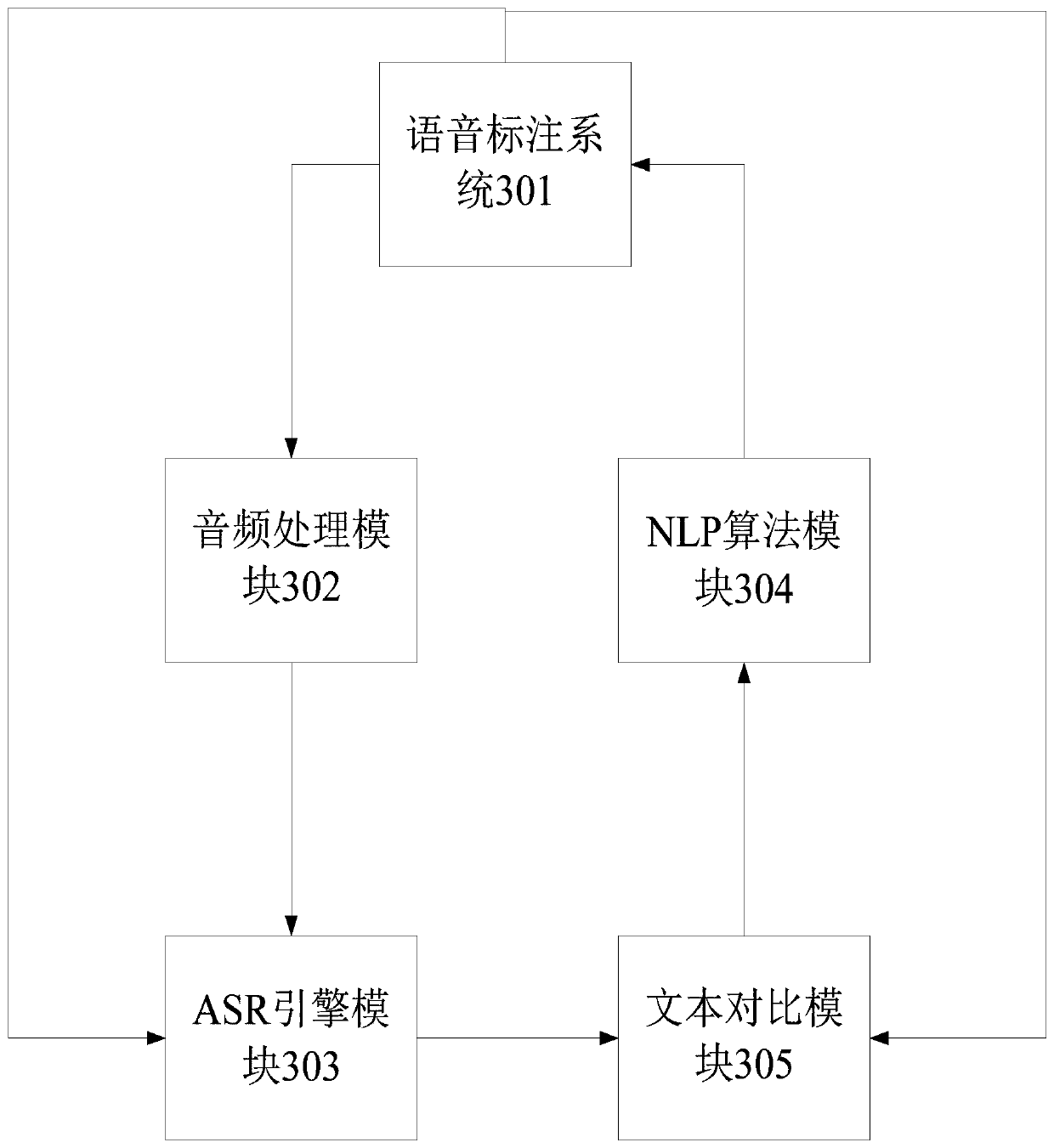

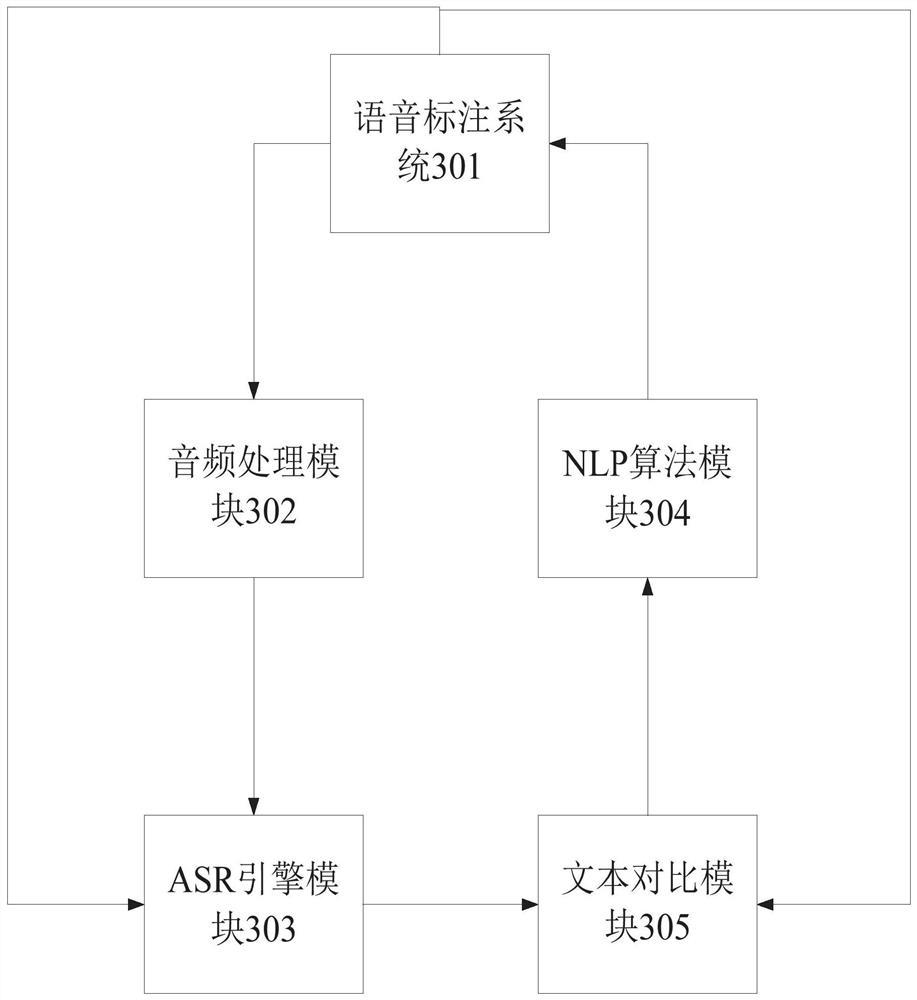

ActiveCN109830230ASave labeling timeImprove labeling efficiencySpeech recognitionSpecial data processing applicationsProduction effectTraining Supports

The invention relates to the field of voice signal processing, in particular to a data labeling method and device based on self-learning algorithm. The method comprises a speech recognition step, a text comparison step, a natural language processing algorithm evaluation step, a natural language processing algorithm prediction step, a data labeling step, a quality inspection step and a self-learning step. The text comparison step is used for comparing a plurality of recognition texts, labeling difference parts of texts and performing sentence breaking processing. The data labeling step is usedfor performing data labeling on an optimal pre-labeled text for a plurality of times by referring to an original recognition text and a prediction text of the difference parts, so as to form a plurality of groups of data labeling texts. The self-learning step is used for inputting the optimal labeled text and a corresponding audio signal into a speech recognition engine, wherein the speech recognition engine is iteratively trained based on the self-learning algorithm. According to the labeling method and device, the data labeling time is greatly saved, the data labeling quality and the data labeling efficiency are effectively improved, the training support is provided for various artificial intelligence products, and the production effect of intelligent products is improved.

Owner:深圳平安综合金融服务有限公司

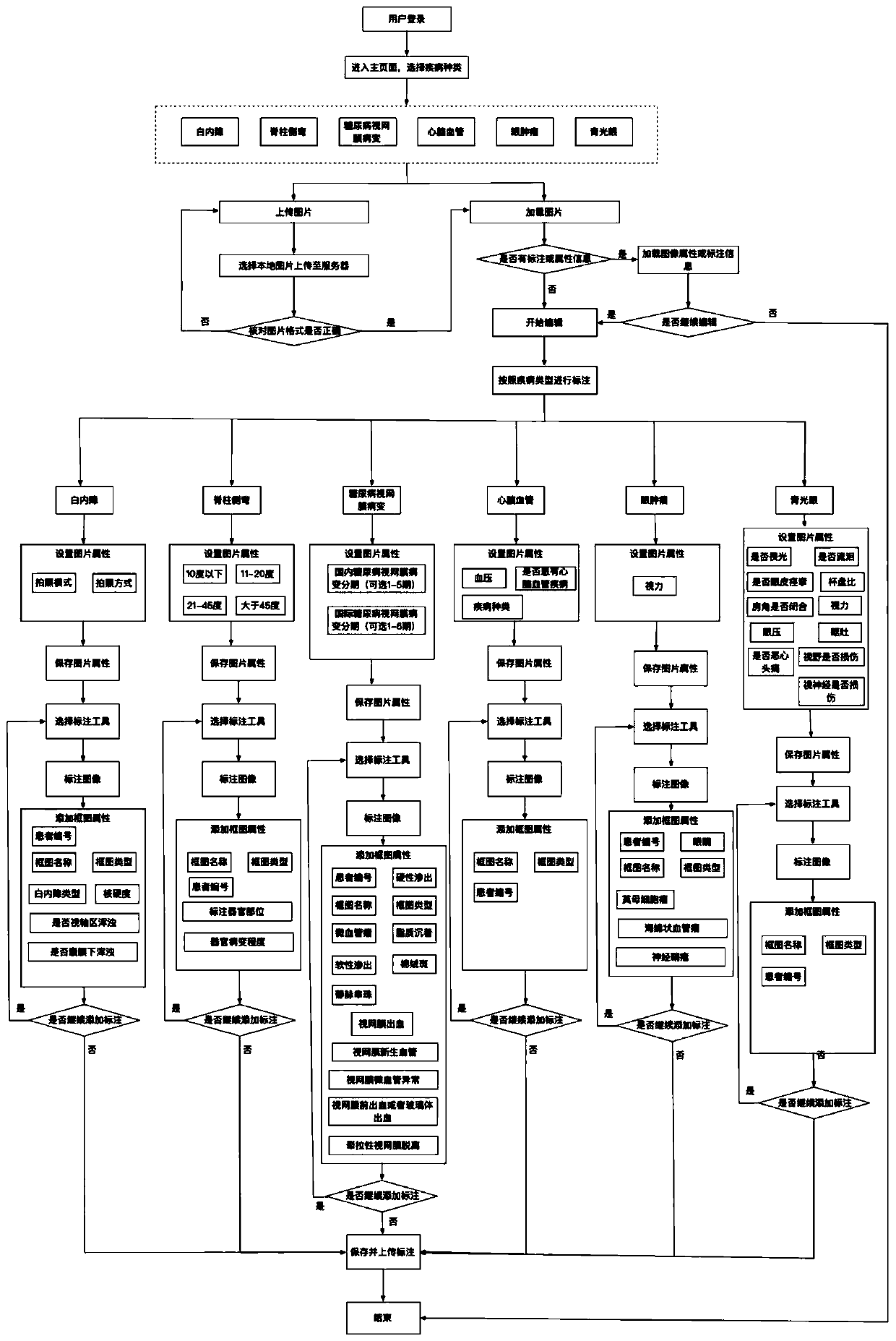

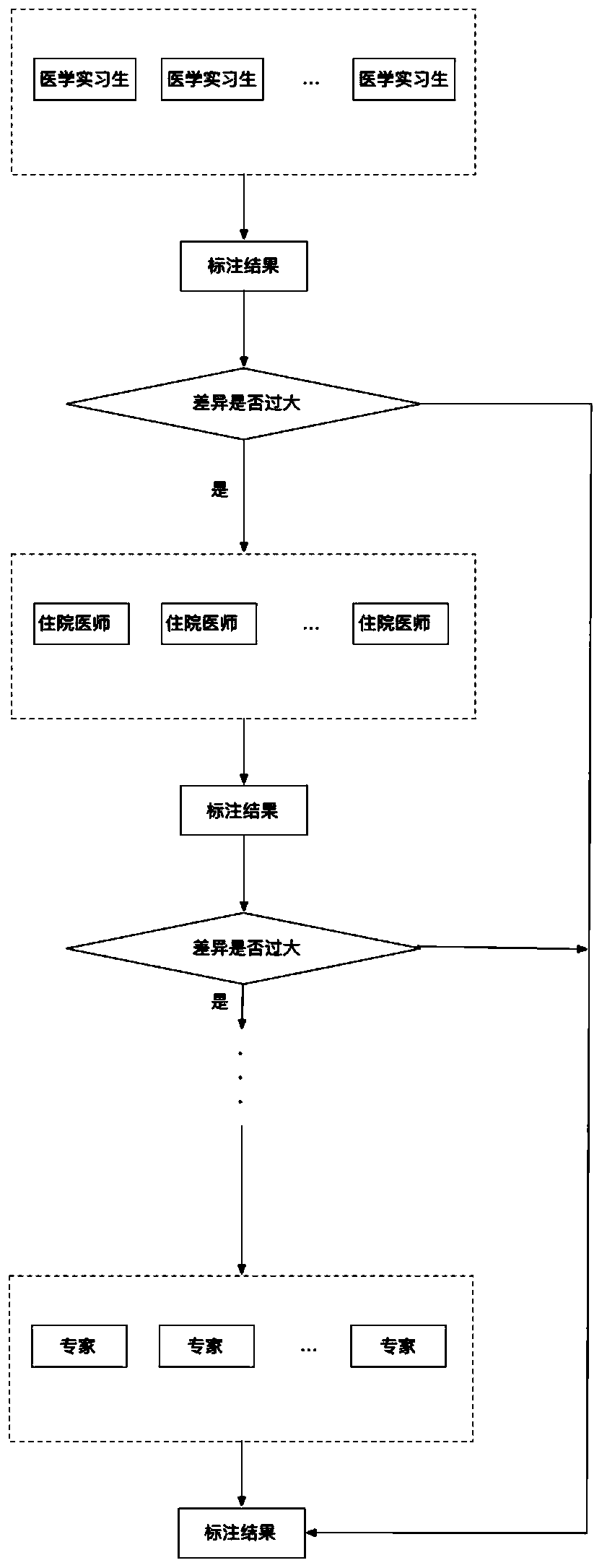

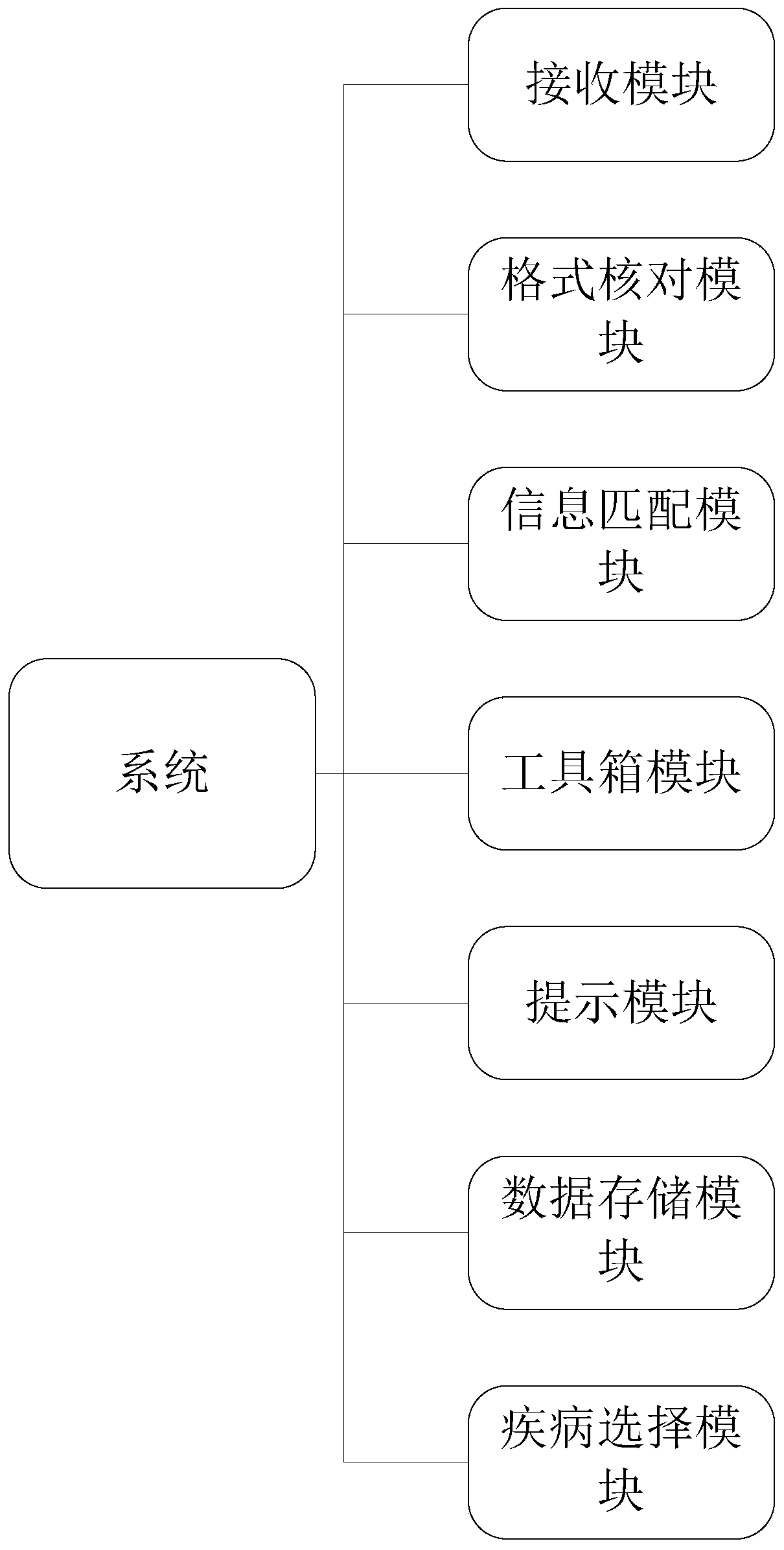

Multi-form medical image data labeling method and system

PendingCN111028924AImprove efficiencyGuarantee the quality of labelingMedical imagesInstrumentsInformation retrievalData labeling

The invention relates to a multi-form medical image data labeling method and system, and the method comprises the steps: receiving a picture uploaded by a user, and checking whether the format is correct or not according to a preset picture format; if yes, uploading the picture, and if not, reminding the user to upload the picture again; extracting picture information to be matched with an information base, and judging whether the picture has annotation or attribute information or not; setting the permission of labeling the picture; providing a labeling tool box for the user according to the disease type; receiving annotation information of the user on the picture, and uploading and storing the annotation information; extracting annotation information of users of the same level for the picture, comparing the annotation information, judging whether the annotation information of the users of the same level is different or not, if not, generating a final annotation result, and if yes, submitting the final annotation result to a next-level user for further annotation. According to the method and system, different labeling tools can be used for labeling images, the labeling requirementsof medical images in various forms are met, and the accuracy of image labeling is improved by adopting a hierarchical labeling process.

Owner:XIDIAN UNIV +2

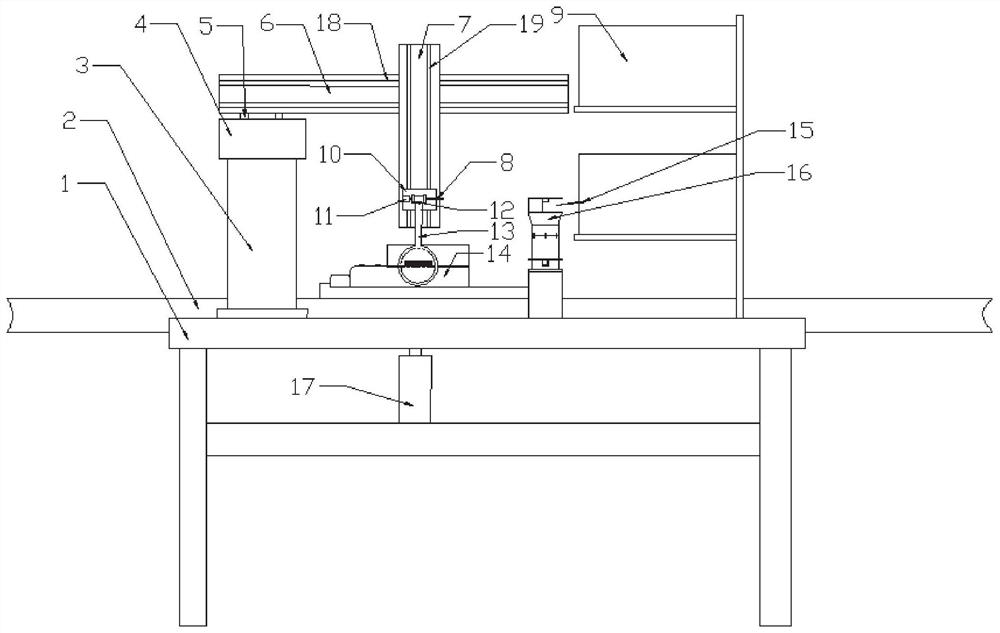

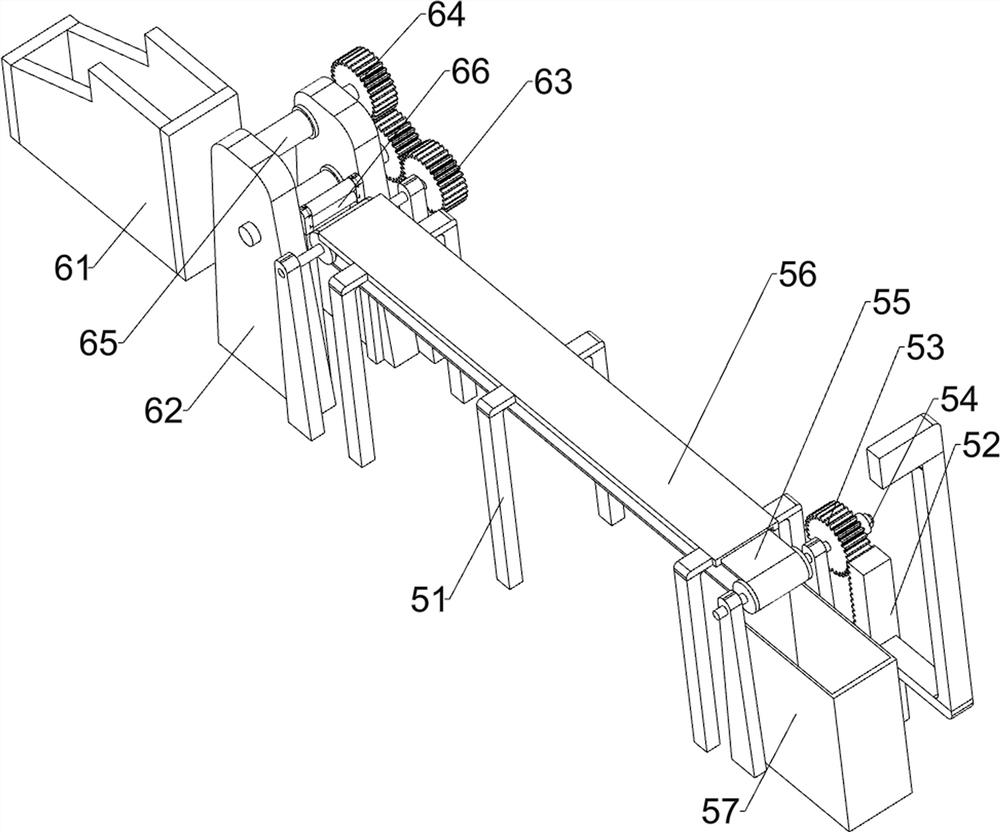

Automatic labeling machine and labeling method

InactiveCN111252326AImprove accuracyGuaranteed labeling qualityLabelling machinesProcess engineeringMechanical engineering

The invention discloses an automatic labeling machine. The automatic labeling machine comprises a machine frame, a carrier rotary table device, a feeding device and a labeling device, wherein the carrier rotary table device, the feeding device and the labeling device are arranged on the machine frame; the feeding device and the labeling device are sequentially arranged in the rotation direction ofthe carrier rotary table device; the feeding device is used for feeding of products and label pieces; the carrier rotary table device is used for conveying the fed products to pass the labeling device; and the labeling device receives the fed label pieces and pasts the label pieces onto the products, and the pasted label pieces are rolled. The invention further discloses a labeling method. The label pieces are pasted onto the products through the labeling device at first, then, a rolling reinforcing mode is adopted, thus, the label pieces are fastened onto the products, and the product labeling quality is ensured.

Owner:HUIZHOU DESAY AUTOMATION TECH

Automatic labeling mechanism and method for label paper

ActiveCN113859698ASuspension stabilityAvoid stickingLabelling machinesStructural engineeringProcess engineering

The invention discloses an automatic labeling mechanism and method for label paper, and belongs to the technical field of labeling machine equipment. According to the technical scheme, the automatic labeling mechanism comprises an adsorption plate and a floating mechanism, the adsorption plate is rotationally connected with a three-axis moving mechanism, and a plurality of ventilation holes communicating with a negative pressure source are formed in the adsorption plate; the floating mechanism comprises a shell and an air blowing mechanism installed on the bottom face of the shell, and a plurality of air exhaust holes are formed in the shell in the circumferential direction; and the adsorption plate can stretch into the shell, and the non-sticking face of the label paper is attached to the surface of the adsorption plate under the action of the air blowing mechanism. According to the automatic labeling mechanism and method for the label paper, tray sticking is avoided in a label paper suspension mode, and under the cooperation effect of the adsorption plate and the air blowing mechanism, accurate sticking of the label paper is achieved.

Owner:国网山东省电力公司营销服务中心(计量中心) +1

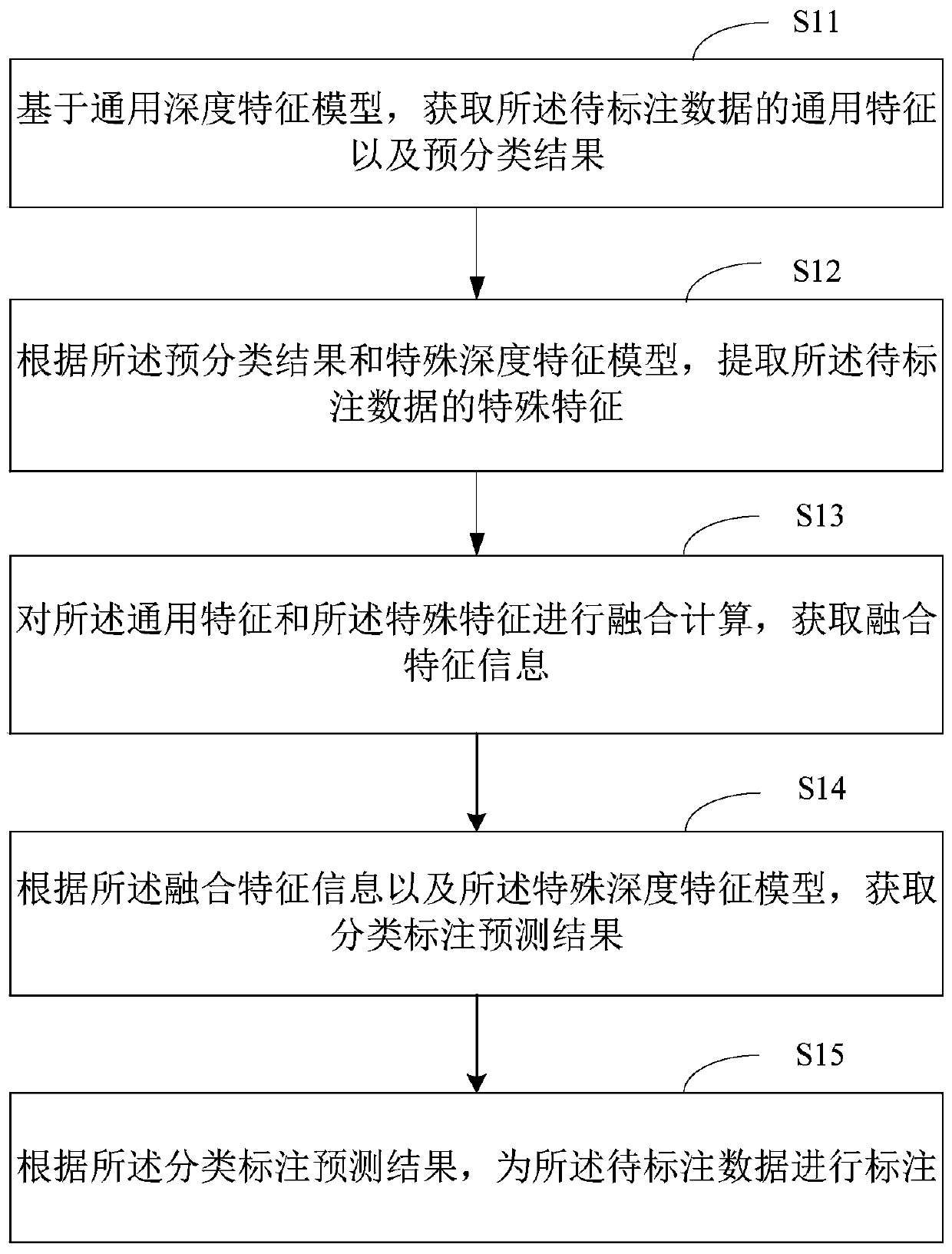

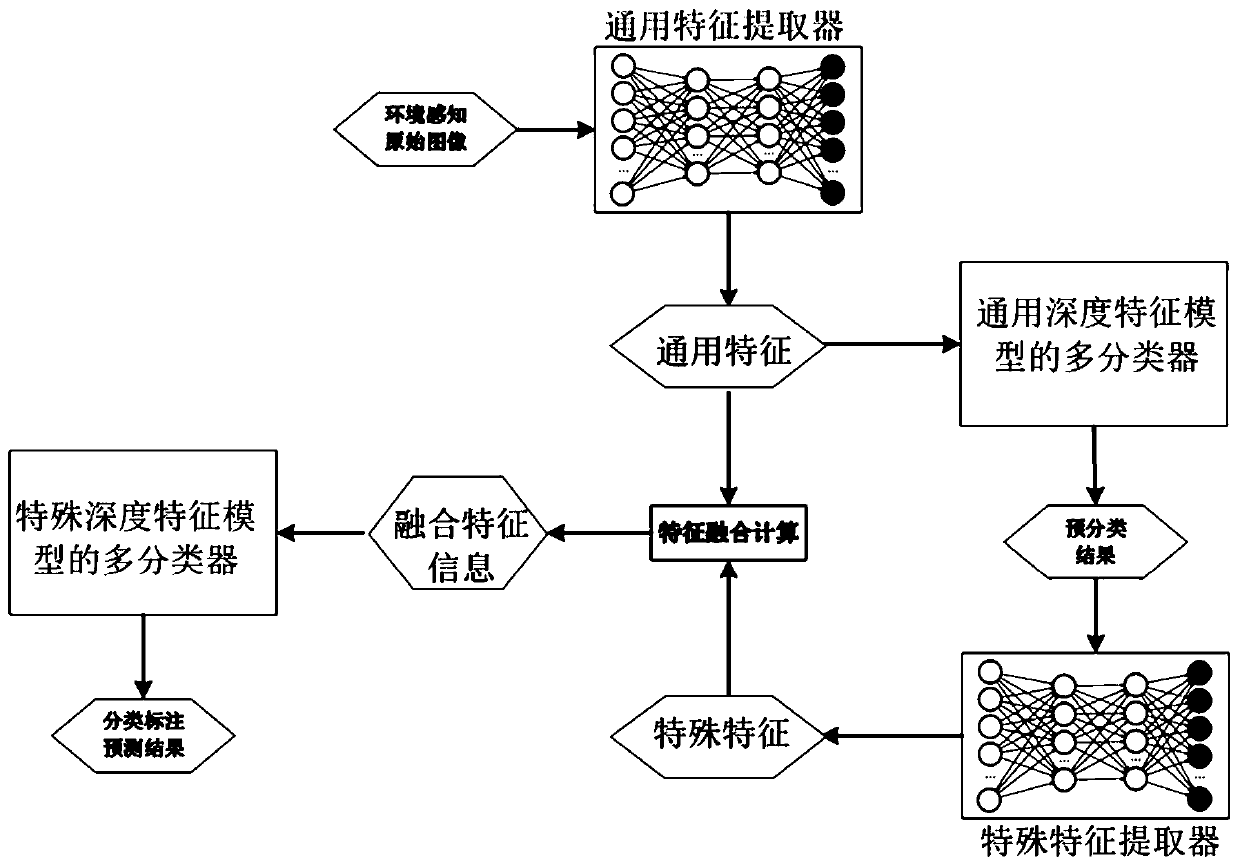

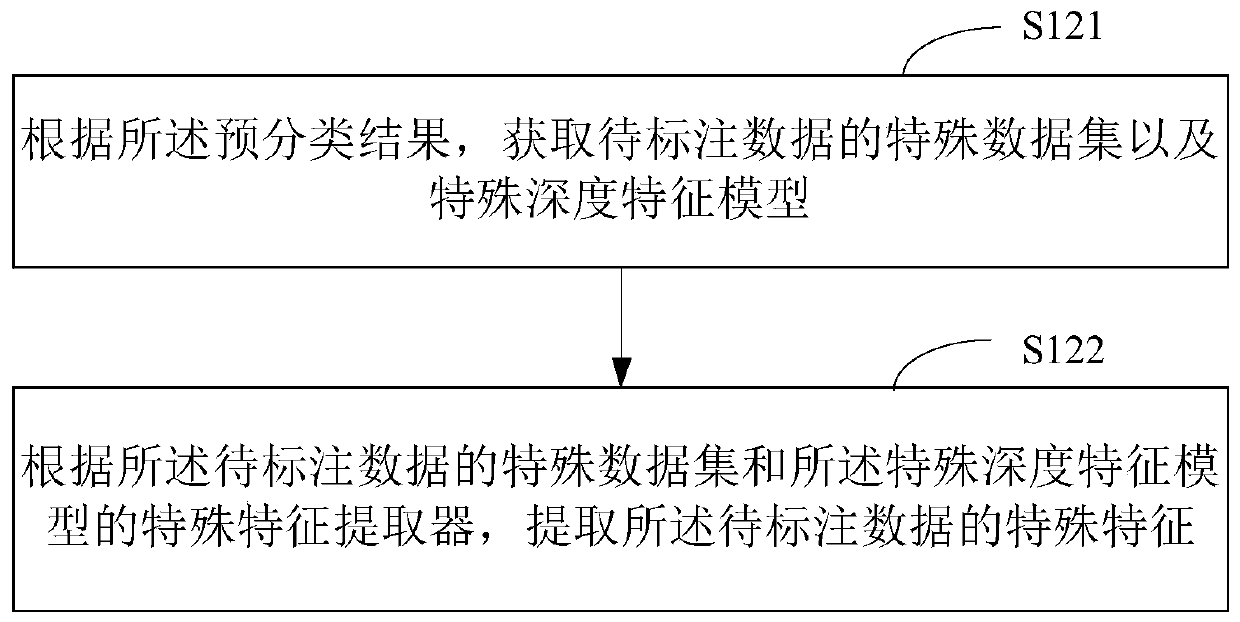

Data labeling method, equipment and device

PendingCN111598120AFully automatedGuaranteed labeling qualityCharacter and pattern recognitionEngineeringData Annotation

The invention relates to a data labeling method, equipment and device. The method comprises the steps of obtaining general features and a pre-classification result of to-be-labeled data based on a general depth feature model; extracting special features of the to-be-labeled data according to the pre-classification result and a special depth feature model; performing fusion calculation on the general features and the special features to obtain fusion feature information; obtaining a classification annotation prediction result according to the fusion feature information and the special depth feature model; and labeling the to-be-labeled data according to the classification labeling prediction result. By utilizing the data annotation method disclosed by the invention, the data annotation costis greatly reduced and the data annotation efficiency is greatly improved on the premise of ensuring the data annotation quality.

Owner:NINGBO GEELY AUTOMOBILE RES & DEV CO LTD +1

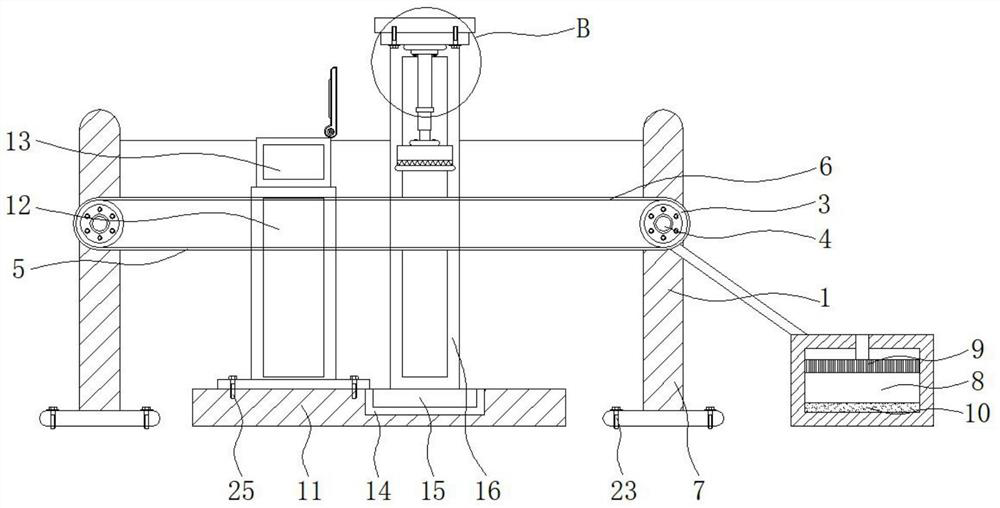

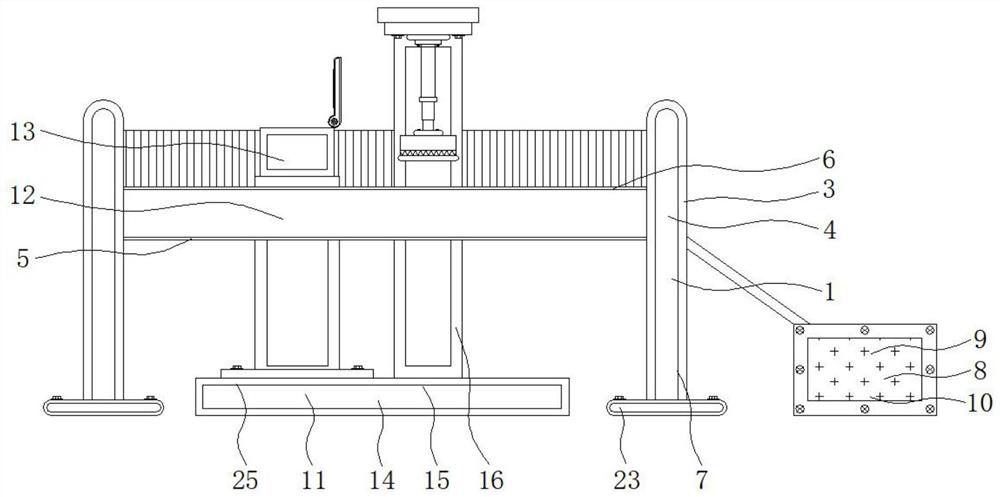

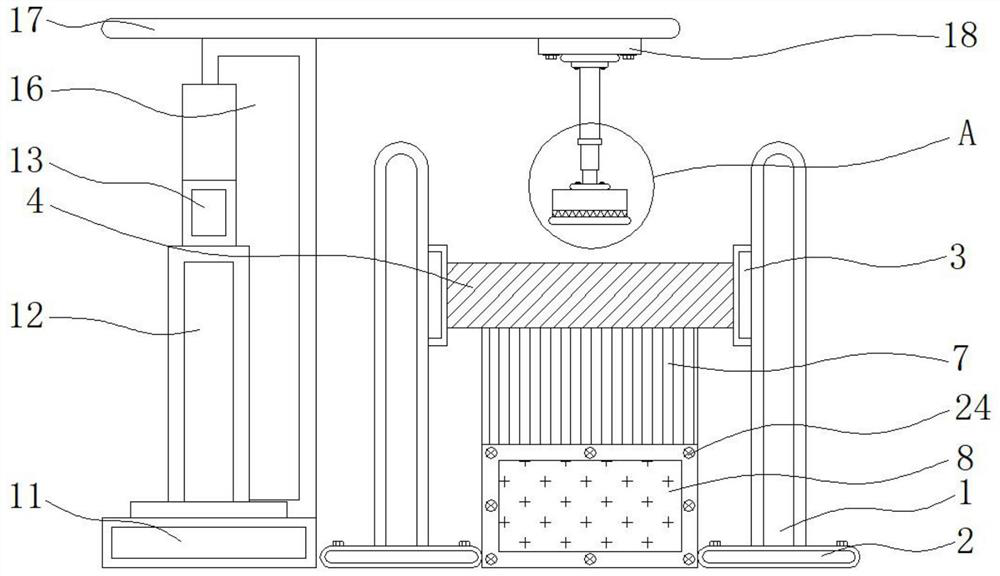

Mobile phone rear cover labeling device for electronic product production and assembly

The invention relates to a labeling device, in particular to a mobile phone rear cover labeling device for electronic product production and assembly. According to the mobile phone rear cover labelingdevice for electronic product production and assembly, labeling is conducted on a mobile phone rear cover through a machine, precise labeling is achieved, label paper is flattened in the later period, and the labeling quality and attractiveness are guaranteed. The mobile phone rear cover labeling device for electronic product production and assembly comprises a base, a driving mechanism and a pasting-mounting mechanism, and a mounting seat is arranged on one side of the top of the base; the top of the mounting seat is connected with the driving mechanism; and one side of the top of the base is connected with the pasting-mounting mechanism. Through a feeding mechanism and a discharging mechanism, the label paper and the mobile phone rear cover are automatically conveyed and matched for labeling; and the driving mechanism drives the pasting-mounting mechanism to move in a reciprocating mode, a suction nozzle is driven to move to adsorb the label paper, then the adsorbed label paper is pasted to the mobile phone rear cover, and automatic labeling is completed.

Owner:徐州启峰智能科技有限公司

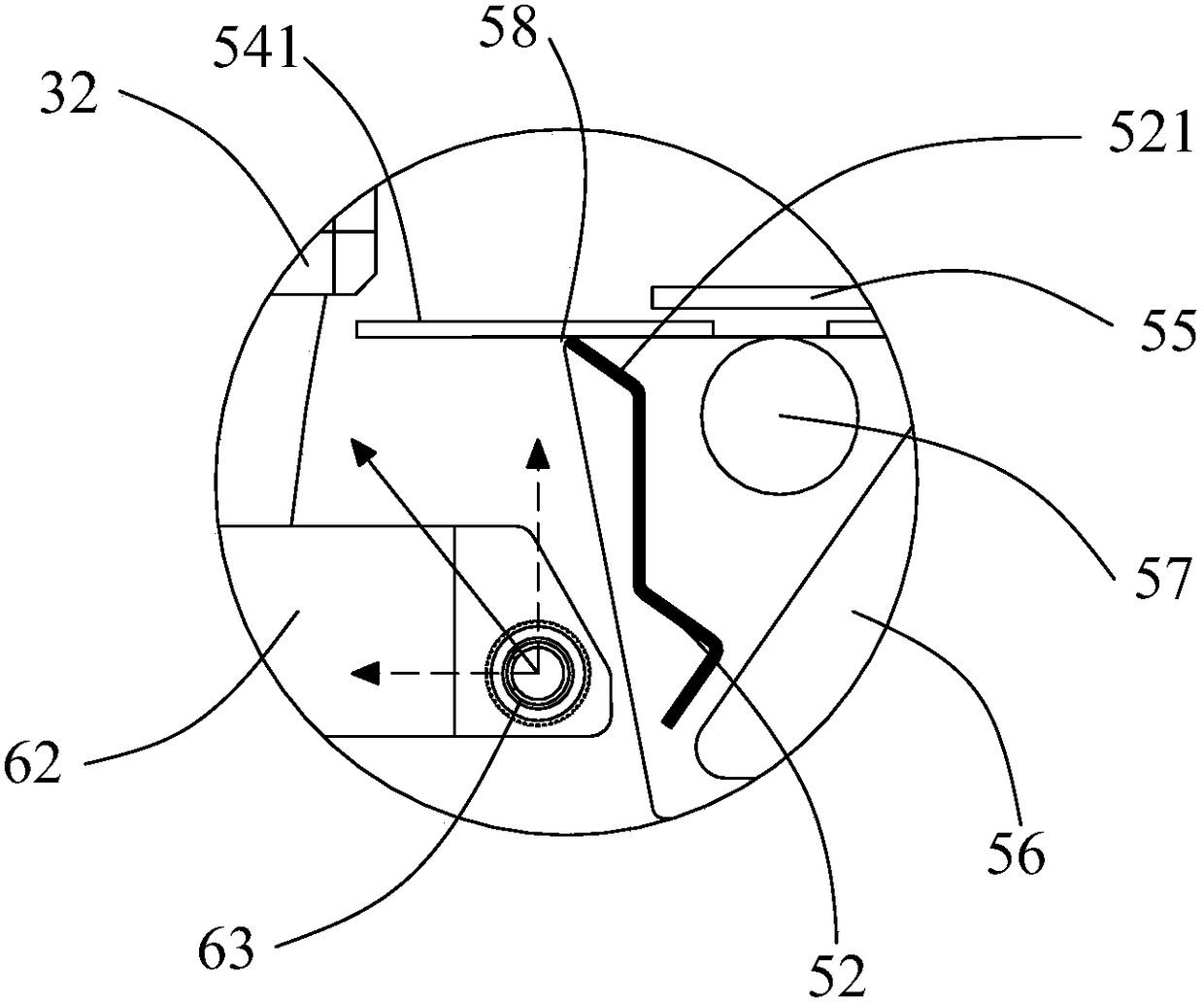

Electric control system and method for monitoring label adsorption at head of labeling machine

ActiveCN105775289BAvoid manual subsidy labeling situationsGuaranteed labeling qualityLabelling machinesElectronic control systemEngineering

Owner:BULLMER ELECTROMECHANICAL TECH

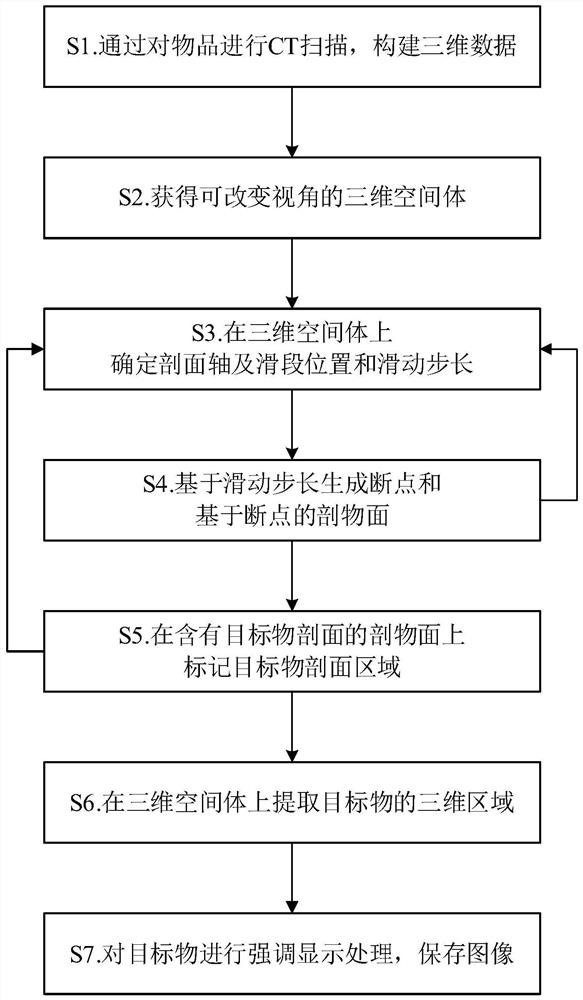

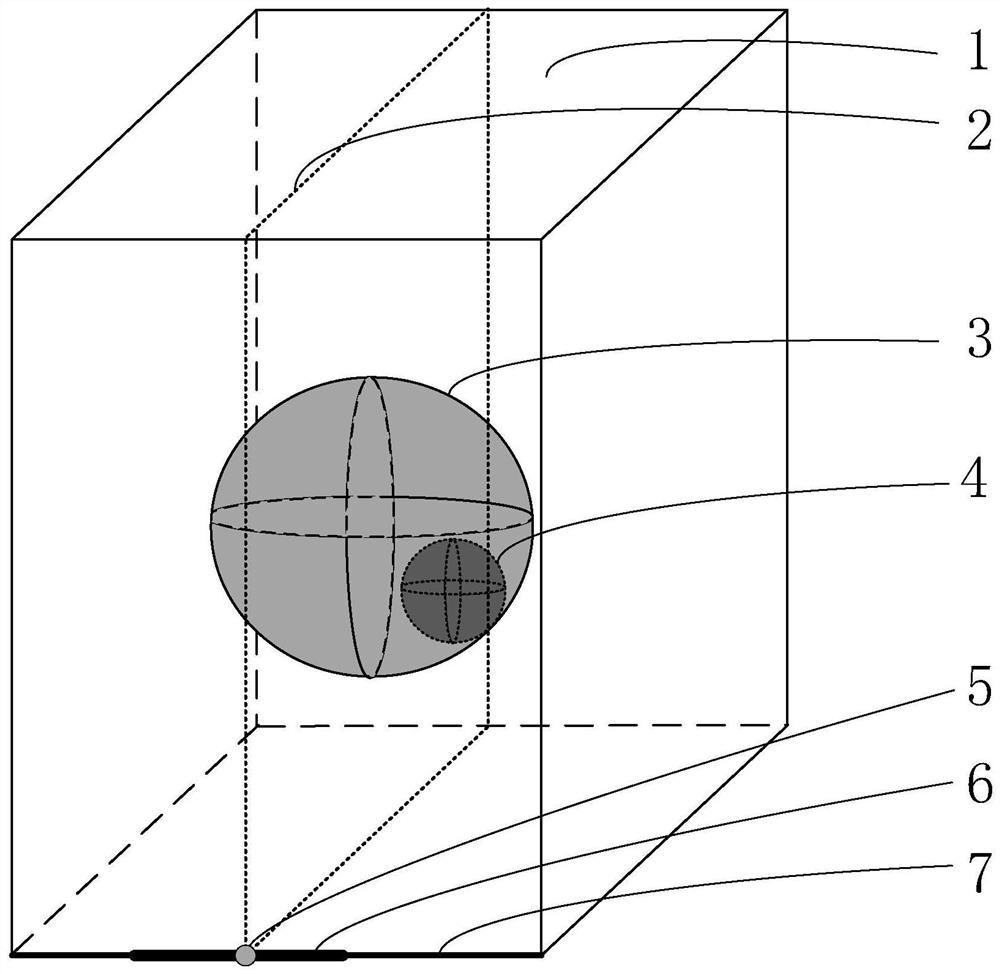

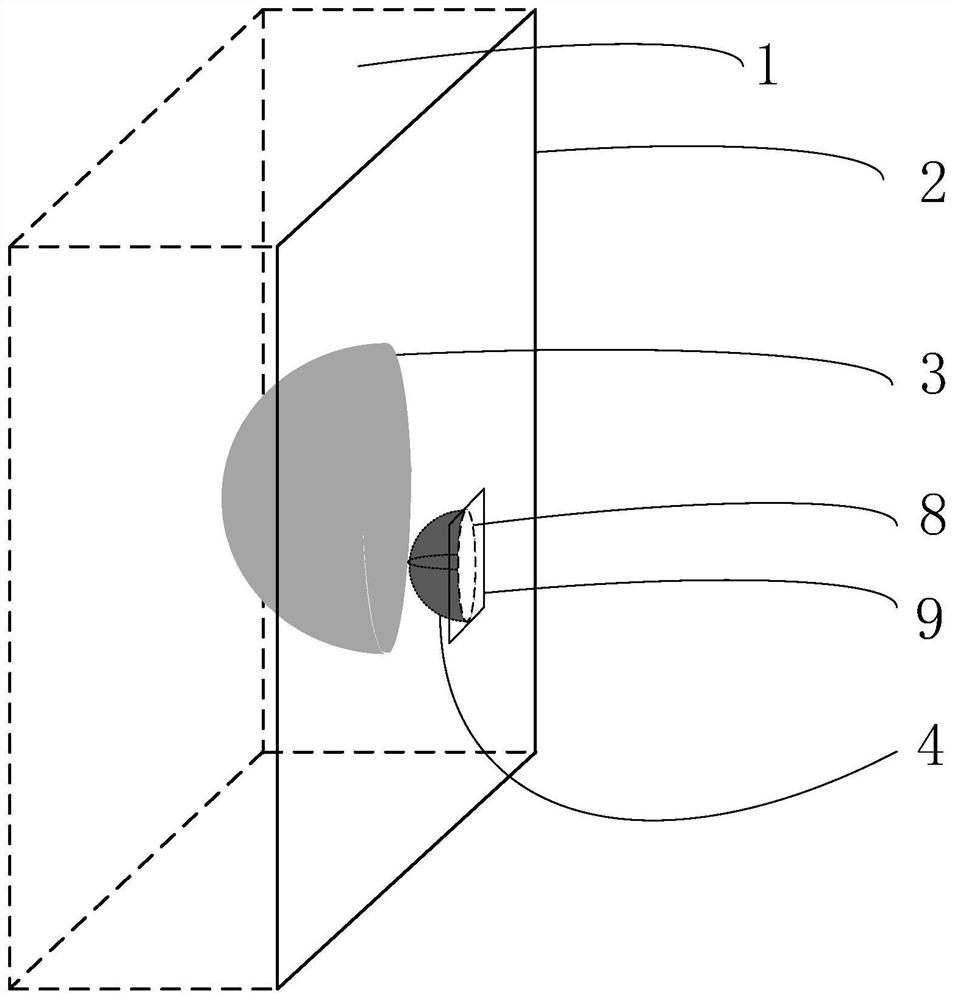

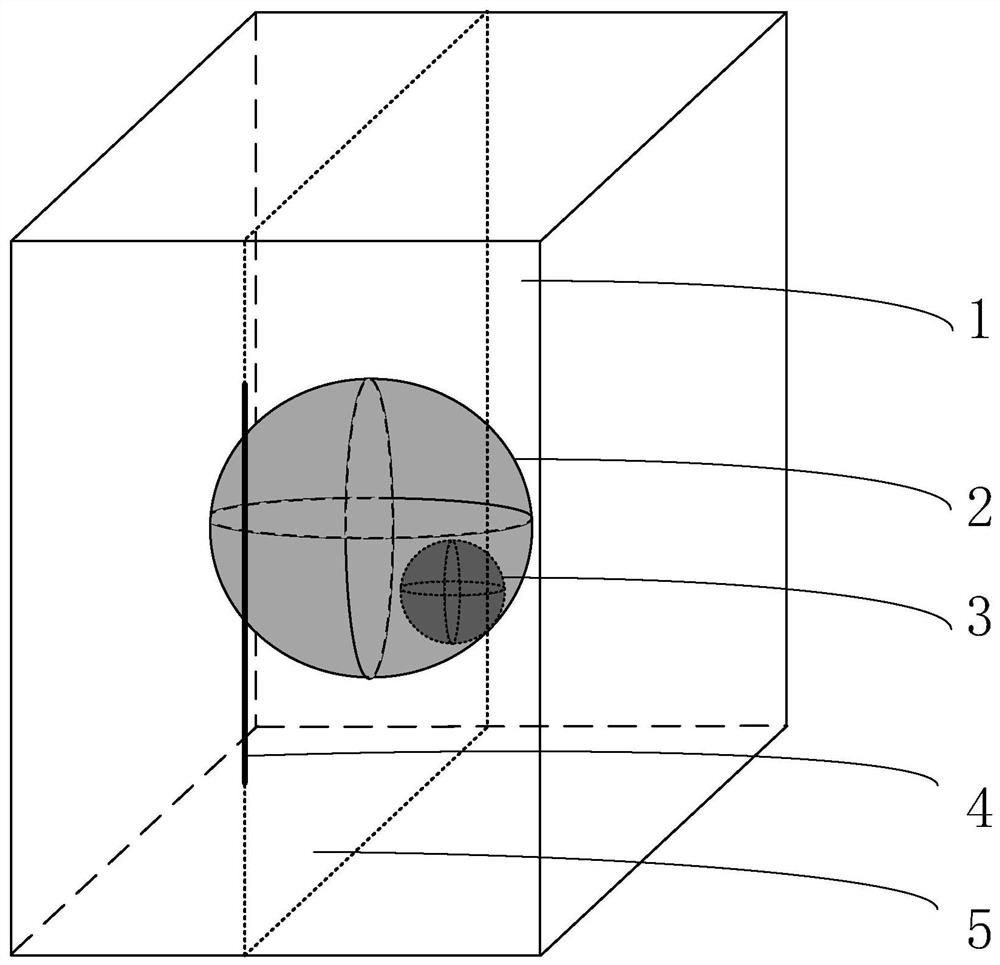

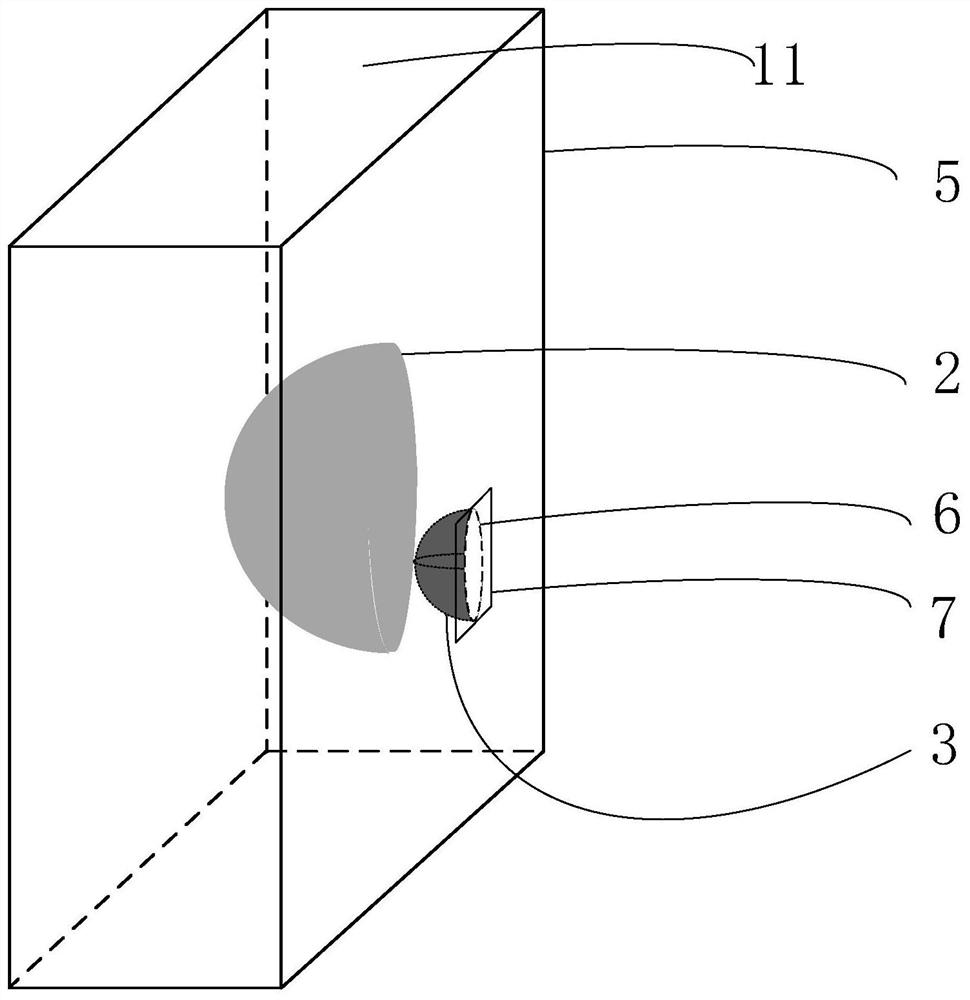

Target object positioning and labeling method and device based on sliding profile

ActiveCN112950664AEliminate Gross ErrorsGuaranteed labeling qualityImage enhancementImage analysisImaging processingComputer graphics (images)

The invention relates to a target object positioning and labeling method and device based on a sliding profile, and belongs to the technical field of security check image processing, and the method comprises the steps: carrying out the CT scanning of an object, and constructing three-dimensional data; displaying a three-dimensional space body visual image with a changeable visual angle; determining a sliding section position and a breakpoint; generating a profile plane perpendicular to the profile axis based on the breakpoint; marking a target object based on the object cutting surface; extracting a three-dimensional area of the target object; and performing emphasized display processing on the target object to obtain a target object image. According to the method and the device provided by the invention, a series of profile maps are arranged on the profile axis, a better position of the profile of the target object in the profile maps can be searched in a sliding manner, the three-dimensional contour of the target object is fitted through an algorithm, and image emphasis processing is carried out, so that the target positioning speed and precision are improved; and the problems that an existing method is low in automation degree, inaccurate in target positioning and labeling, tedious in operation, long in time consumption and the like are solved, and the labeling quality of the target object is effectively guaranteed.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

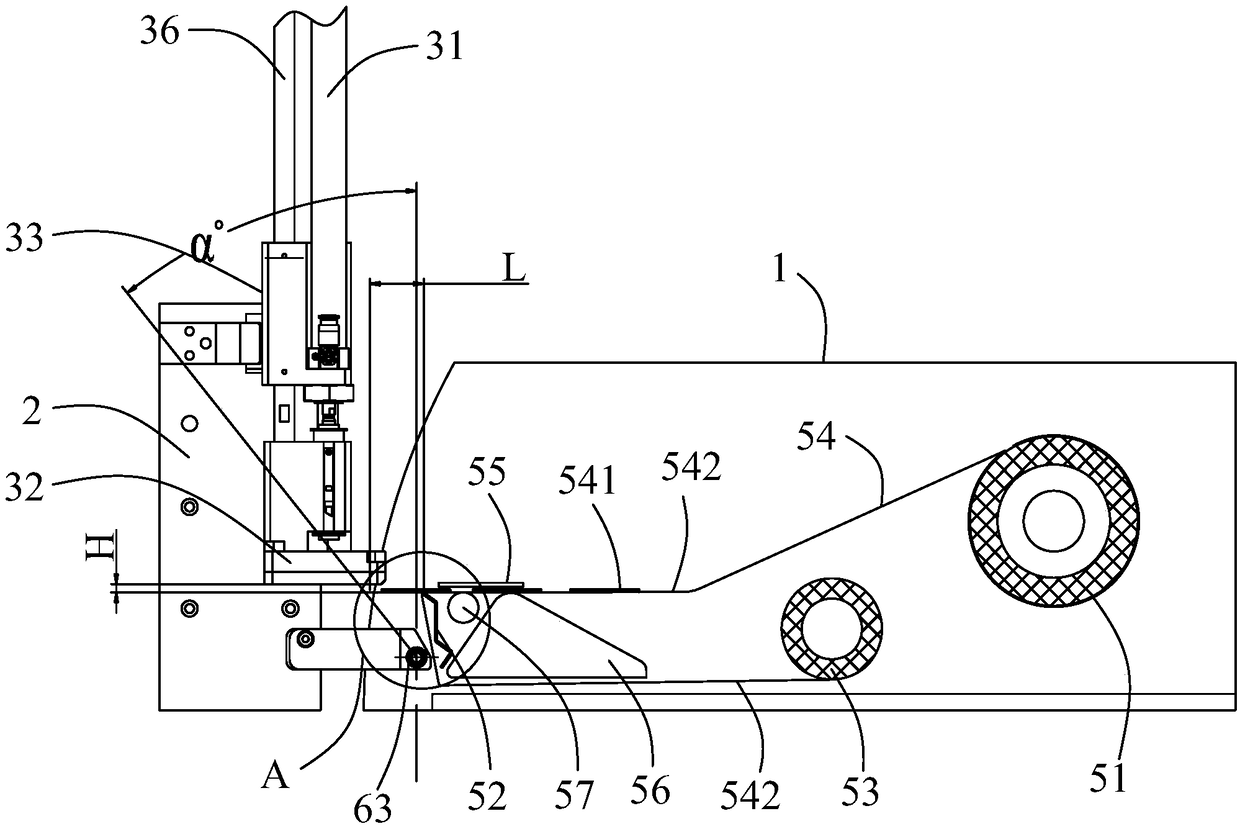

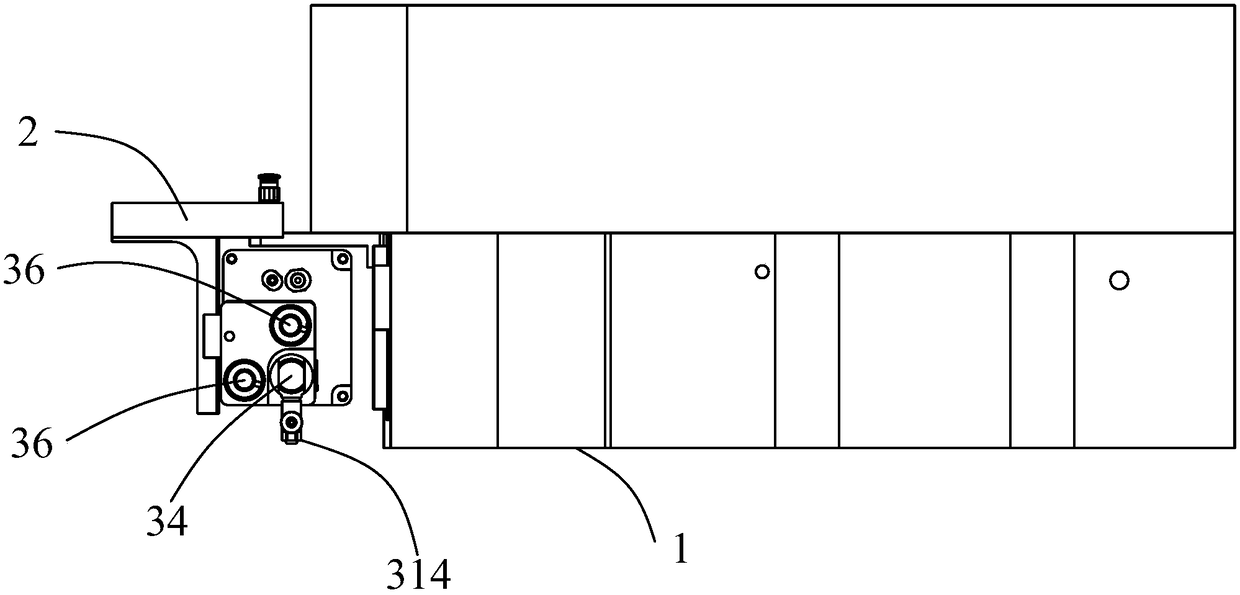

a labeling machine

ActiveCN105775285BImprove labeling qualityGuaranteed labeling qualityLabelling deformable materialsLabelling machinesComputer scienceVertical distance

The invention provides a label pasting machine. The label pasting machine comprises a frame, a label pasting arm mechanism and a printer; and the label pasting arm mechanism includes a label pasting arm capable of moving up and down, and a suck mounted at the lower end of the label pasting arm. The label pasting machine further comprises a fixed block mounted on the frame; the label pasting arm mechanism includes a label pasting arm fixed base for supporting the label pasting arm; the label pasting arm fixed base and the fixed block are connected through a position adjusting mechanism; and the position adjusting mechanism is used for adjusting a horizontal distance L from an absorbing surface at the lower end of the sucker to a label outlet in the front end of the printer in the front-back direction and a vertical distance H in the up-down direction. The label pasting machine adjusts the horizontal distance L and the vertical distance H between the absorbing surface at the lower end of the sucker and the label outlet in the front end of the printer in an optimal range through the position adjusting mechanism according to the size specification of each label; and the optical range guarantees labels, delivered from the label outlet of the printer, capable of being accurately and stably absorbed on the absorbing surface at the lower end of the sucker, so that the label pasting quality is improved.

Owner:BULLMER ELECTROMECHANICAL TECH

Labeling device for water quality improver packaging

InactiveCN111634518APrevent fallingSafe labelingConveyorsLoading/unloadingProcess engineeringIndustrial engineering

The invention discloses a labeling device for water quality improver packaging, and relates to the technical field of water quality improver production equipment. The labeling device specifically comprises a supporting column and a material collecting box, a supporting seat is fixedly connected below the supporting column, a bearing is fixedly connected to the inner part of the supporting column,a conveying belt is connected to the right side of a rotating rod, a guardrail is fixedly connected to the front end of the supporting column, the material collecting box is located on the right sideof a guide plate, and a push rod is arranged in the inner part of the material collecting box. Compared with an existing common labeling device for water quality improver packaging, the labeling device for water quality improver packaging has the advantages that through the arrangement of a telescopic rod, an electric heating wire and a bonding plate, the distance between a pressing block and a labeling product on the conveying belt can be effectively adjusted through the telescopic rod, the labeling device can adapt to water quality improver packaging products with different specifications; the electric heating wire helps labels to be rapidly attached to the packaging products; and the labels in a label box are not prone to falling off when the labeling operation is carried out through the bonding plate.

Owner:ANHUI HUANGHUAI VETERINARY MEDICINE

An automatic labeling device for sealing the blast hole of the shell of the perforating bullet

ActiveCN112061533BImprove accuracyIncrease productivityConveyor partsLabelling machinesControl engineeringProcess engineering

The invention relates to the field of automatic labeling equipment, in particular to an automatic labeling equipment for sealing the blast hole of the casing of a perforating bullet. It includes an annular conveying line, a feeding mechanism, a labeling mechanism and a feeding mechanism. The feeding mechanism, the labeling mechanism and the unloading mechanism are distributed along the running direction of the circular conveying line. A cartridge case tray is placed on the circular conveying line. The circular conveying line drives the cartridge case tray to move along it, and the cartridge case tray is lifted up by the positioning jacking mechanism so that the cartridge case tray is positioned and detached from the circular conveying line to stop moving. The beneficial effects of the invention are: automatic labeling is realized, production efficiency is improved, and the cartridge casing tray can be kept stationary at a designated position through the jacking mechanism, the accuracy of positioning and labeling is improved, and the quality of labeling is guaranteed.

Owner:SICHUAN PETROLEUM PERFORATING EQUIP

Image labeling method and device

ActiveCN111367445BImprove annotation qualityImprove labeling efficiencyInput/output processes for data processingRadiologyImage detection

The present application provides an image tagging method and device, wherein the method includes: receiving an image display instruction and acquiring an image to be tagged according to the image display instruction; displaying the image to be tagged in a canvas in a target browser; Real-time monitoring of the mouse click event in the canvas canvas, if the real-time monitoring mouse click event is detected, the position to be marked in the image to be marked is obtained according to the real-time monitoring mouse click event, and a preset mark element is applied The position to be marked is marked to obtain a marked image. The present application can improve the quality and efficiency of image labeling, and further can improve the accuracy and efficiency of transaction voucher image classification or intelligent driving image detection realized by applying image labeling results.

Owner:CHINA CONSTRUCTION BANK

Labeling device for glass bottles

PendingCN114194544AConvenient labeling workGuaranteed labeling qualityLabelling machinesLabelling short rigid containersEngineeringBottle

The invention relates to a labeling device, in particular to a labeling device for glass bottles. The invention provides the labeling device for the glass bottle, which does not need manual labeling, is high in productivity and ensures the quality of finished products. The labeling device for the glass bottle comprises a base used for installing the whole device; the first supporting frame is arranged on the front side of the top of the base; the servo motor is arranged at the top of the first supporting frame; the second supporting frame is arranged on one side of the top of the base; the third supporting frame is arranged in the middle of the top of the base; the output end of the servo motor is provided with the first rotating shaft. According to the labeling machine, the clamping mechanism and the attaching mechanism are matched, the clamping mechanism clamps the discharged bottles, so that labeling work is facilitated, the attaching mechanism makes contact with the bottles, labels are further attached, and the labeling quality is guaranteed.

Owner:刘齐花

Locating pneumatic pressing apparatus for square lithium ion and nickel-hydrogen battery label

ActiveCN101439775BGuaranteed labeling qualityReduce training timeLabelling machinesLithiumEngineering

The invention relates to a pneumatic labeling device for labeling and positioning a square lithium ion and nickel-hydrogen cell, which relates to a cell labeling device. The pneumatic labeling device solves the problems that the prior labeling station has gas between a battery cell and a brand label in labeling, has gas bubbles on the cell after labeling, has flexure and is easy to deflect, needsskilled operators, and has low production efficiency, and the labeling quality is hard to ensure. An L-type cylinder bracket is fixedly arranged on the upper end face of a second-level step of a ladder pedestal; the output end of the cylinder penetrates through a cylinder mounting hole to be fixedly connected with an upright arm of a bracket of a press roll assembly which is arranged between two cross arms of the bracket of the press roll assembly through a shaft of the press roll assembly; a dual-positioning mould is fixedly arranged on the upper end face of a first-level step of the ladder pedestal; the cell is arranged in a cell positioning slot of the dual-positioning mould; and a commodity label is placed in a commodity label positioning slot. The pneumatic labeling device has the advantages of having no bubbles and folds after the commodity label is affixed with the cell, lightening the labor intensity for workers, improving the production efficiency and the like.

Owner:哈尔滨光宇电子有限公司

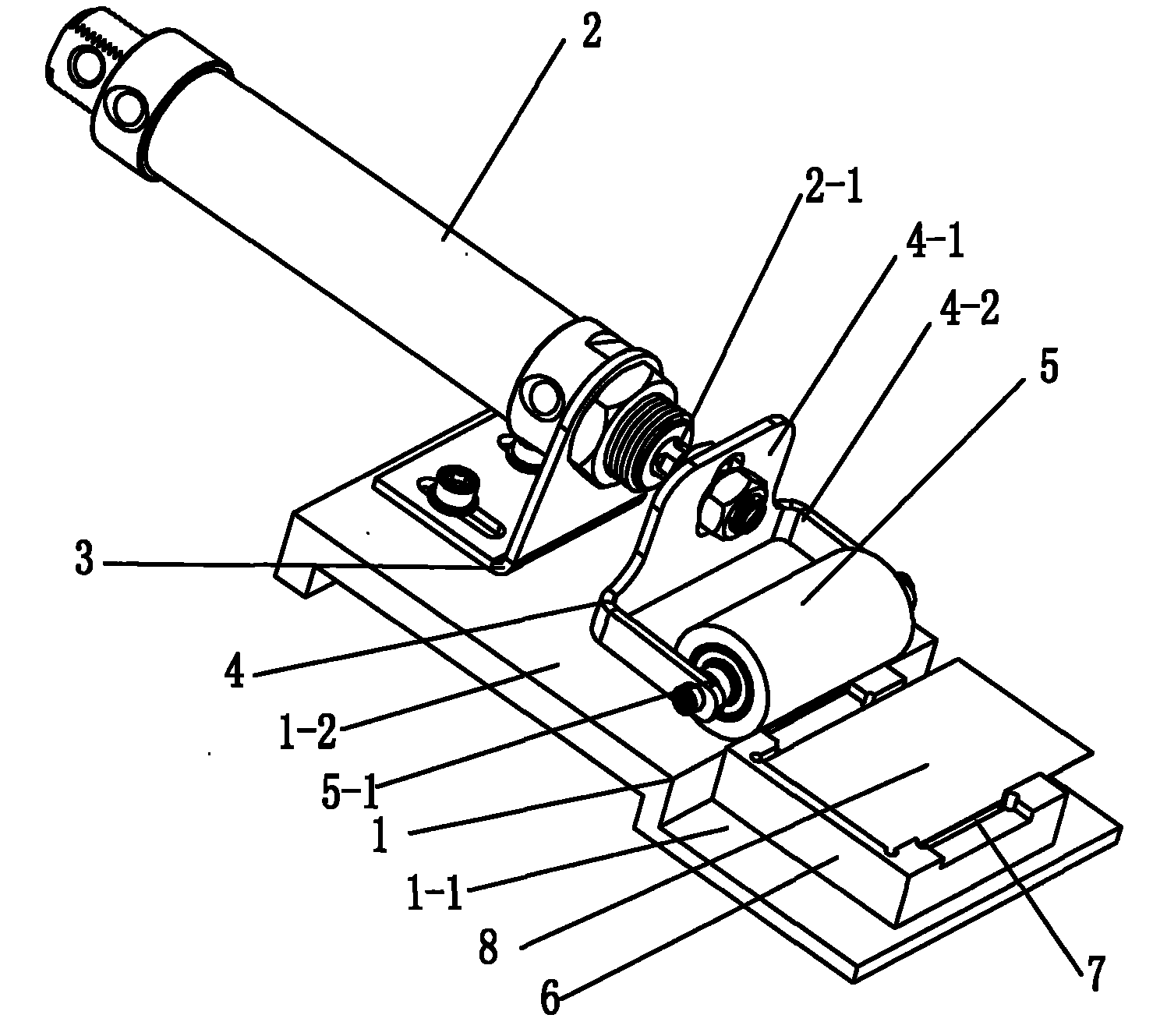

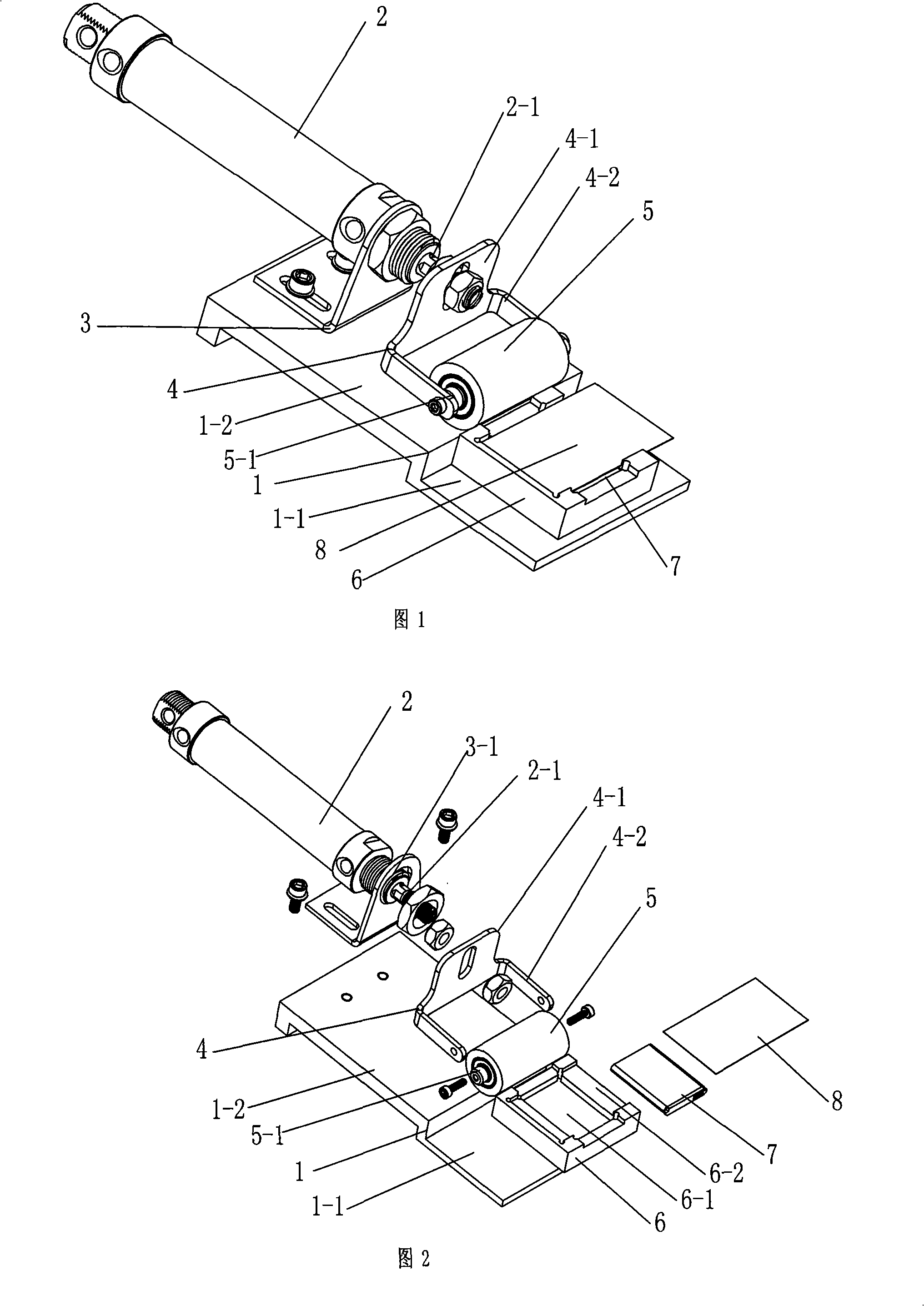

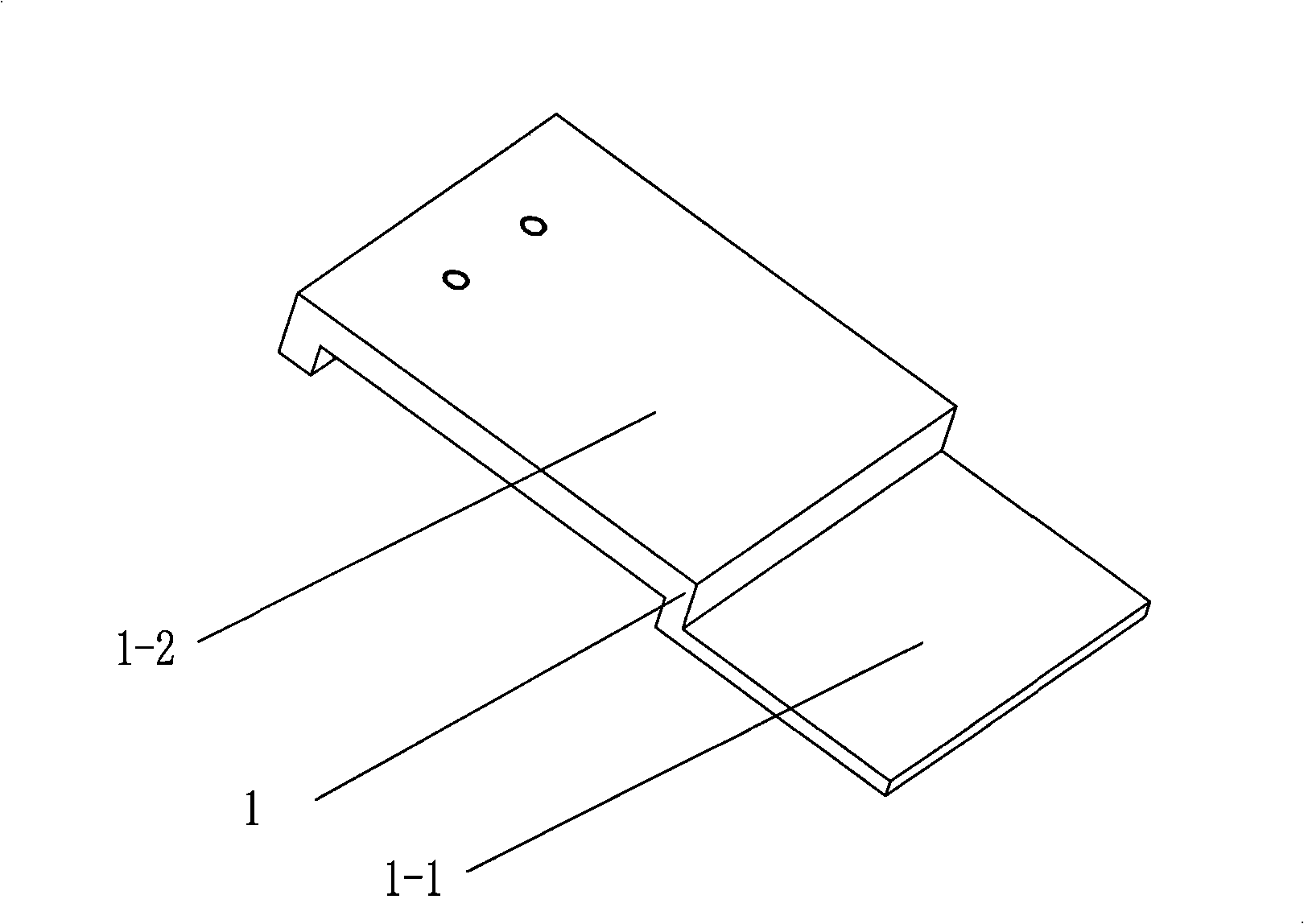

Corner labeling mechanism of labeling machine

ActiveCN104494978BReduce wasteSimple structureLabelling flat rigid surfacesLabelling machinesEngineeringMechanical engineering

The invention discloses a corner labeling mechanism of a labeling machine. The corner labeling mechanism comprises a rack, a roller pressing motor, an eccentric wheel, a roller wheel bracket, a guide track, a first roller wheel and a second roller wheel, wherein the first roller wheel and the second roller wheel are perpendicular to each other and are arranged on the roller wheel bracket; the rack comprises a base and a fixing plate; the fixing plate is vertically and fixedly arranged on the base; the roller pressing motor is fixedly arranged on the base; the guide track is arranged on the fixing plate; a sliding groove matched with the guide track is formed in the inner side surface of the roller wheel bracket; the output end of the roller pressing motor and the input end of the eccentric wheel are in transmission connection; the eccentric end of the eccentric wheel is in transmission connection with one end of the roller wheel bracket; the roller wheel bracket is driven to make reciprocation straight line movement along the guide track. The corner labeling mechanism is simple and compact in structure, the operation is simple, the production procedures are effectively improved, the labeling efficiency is improved, and the labeling quality and the precision are effectively ensured. The labor is greatly saved, the production cost is lowered, and the resource waste is reduced.

Owner:江西弘格精密机械有限公司

A data labeling method and device based on a self-learning algorithm

ActiveCN109830230BSave labeling timeImprove labeling efficiencyNatural language data processingSpeech recognitionAlgorithmSpeech sound

Owner:深圳平安综合金融服务有限公司

Face-shaped element configuring method in computer graphics

InactiveCN101183461BImprove the efficiency of automatic annotationSolve the problem of intelligent configurationMaps/plans/chartsSpecial data processing applicationsAuto-configurationAlgorithm

The invention relates to a configuration method for area pattern in computer drawing, belonging to the technical field of computer drawing, which comprises the following steps: step one, importing the geography data into the computer and then judging the pattern type waiting for noting in the geography data; step two, deciding the noting mode type of the noting pattern according to the pattern type; step three, configuring the pattern waiting for noting according to the configuration rule of the noting mode type. The invention divides the noting configuration of the area pattern into five basic modes according to the substantive characteristics and the configuration rules of the patterns of the water system and settlement place, provides the automatic configuration arithmetic of noting ofdifferent modes according to the geometrical characteristics of the modes, and resolves the problems of collision or shelter of the different noting modes in topographic maps with full elements. The invention has the advantages of improved efficiency of automatically noting the area pattern and enhanced noting quality of the map.

Owner:常熟紫金知识产权服务有限公司

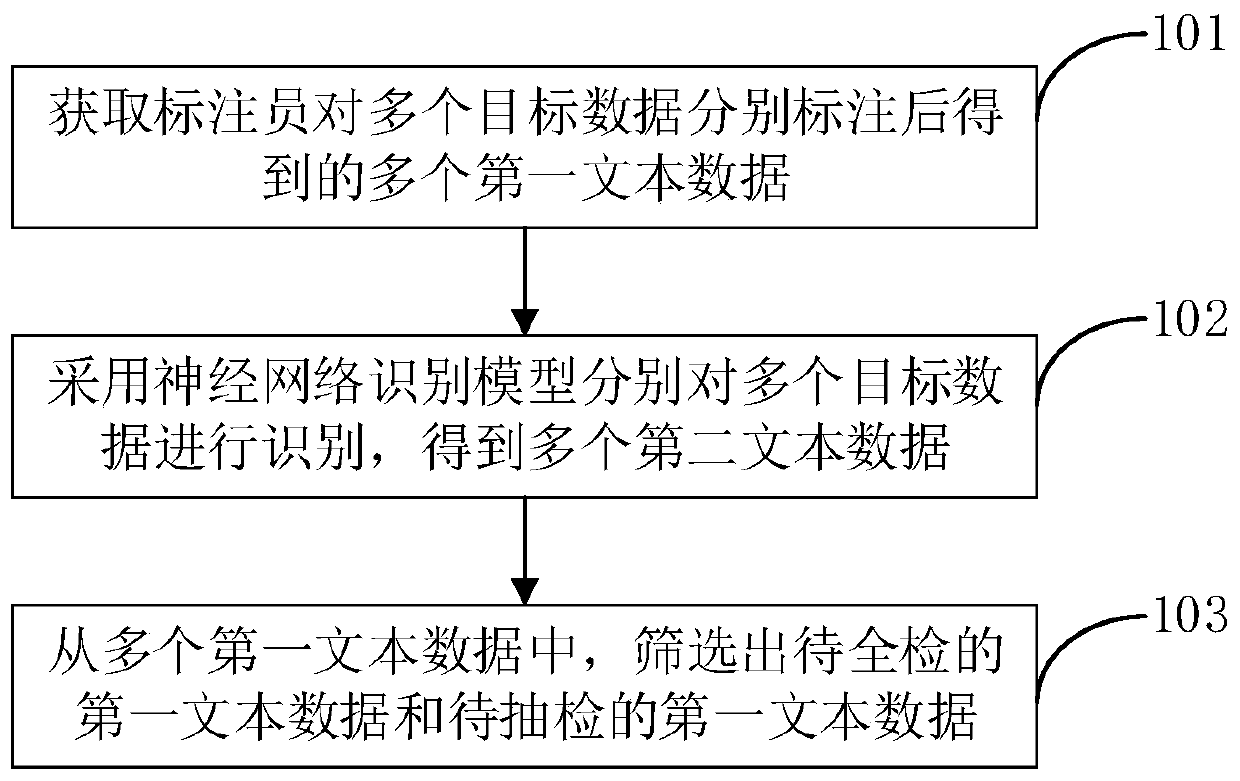

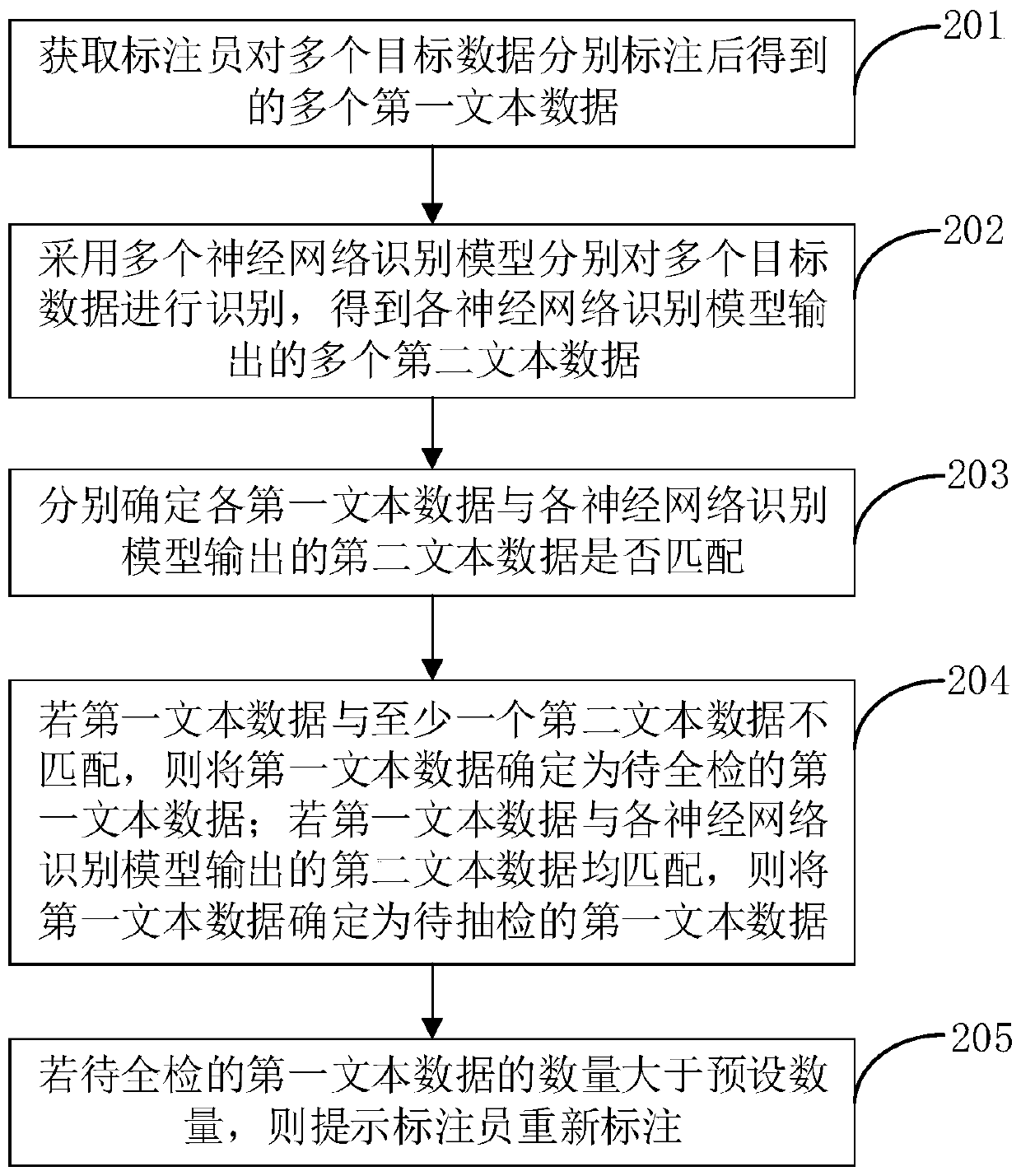

Labeling quality detection method and device, computer equipment and storage medium

InactiveCN110610004AGuaranteed labeling qualityReduce in quantityNeural architecturesText database queryingData matchingData mining

The invention relates to an annotation quality detection method and device, computer equipment and a storage medium. The method comprises the steps of obtaining multiple parts of first text data obtained after a labeler labels multiple parts of target data separately; a neural network recognition model is adopted to recognize the multiple parts of target data, and multiple parts of second text data are obtained; screening out first text data to be subjected to full inspection and first text data to be subjected to casual inspection from the plurality of parts of first text data; wherein the first text data to be subjected to full inspection is first text data not matched with the second text data, and the first text data to be subjected to casual inspection is first text data matched withthe second text data. According to the embodiment of the invention, on the premise of ensuring the labeling quality, the number of full inspection is reduced, and the detection efficiency is improved.

Owner:SHENZHEN ZHUIYI TECH CO LTD

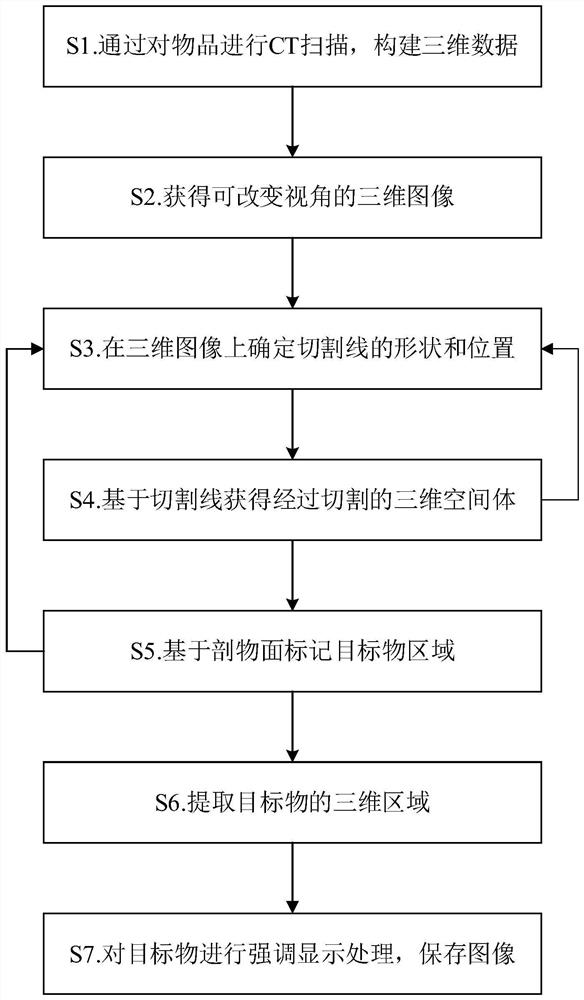

Target object positioning and labeling method and device based on profile map

ActiveCN112907670AEliminate Gross ErrorsGuaranteed labeling qualityImage enhancementImage analysisImaging processing3d image

The invention relates to a target object positioning and labeling method and device based on a profile map, and belongs to the technical field of security check image processing, and the method comprises the steps: carrying out the CT scanning of an object, and constructing three-dimensional data; displaying a three-dimensional image of which the visual angle can be changed; determining a cutting line; obtaining a cut three-dimensional space body based on the cutting line; marking a target object based on the object cutting surface; extracting a three-dimensional area of the target object; and performing emphasized display processing on the target object to obtain a target object image. According to the method and the device provided by the invention, the target object area can be directly positioned and marked on the profile map by using the profile map under a single view angle, and the three-dimensional contour of the target object is fitted through an algorithm and image emphasis processing is performed, so that the target object positioning speed and precision are improved; and the problems that an existing method is low in automation degree, inaccurate in target positioning and labeling, tedious in operation, long in time consumption and the like are solved, and the labeling quality of the target object is effectively guaranteed.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

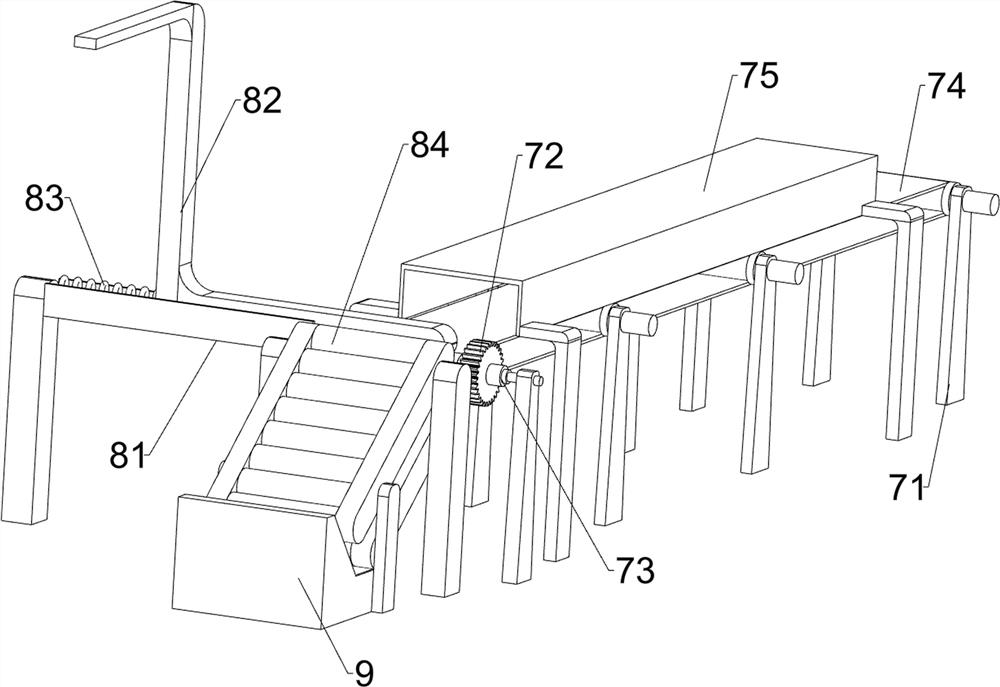

Automatic jumper labeling device for optical fiber connector

PendingCN111661440AAutomate operationsImprove labeling efficiencyLabelling machinesWebs handlingFiberOptical fiber connector

The invention discloses an automatic jumper labeling device for an optical fiber connector. The automatic jumper labeling device comprises a rack, wherein a label placing table is arranged on the rack, a fiber dropping slot is arranged on the label placing table, a label feeding device for feeding label stickers to the fiber dropping slot is arranged on the rack, an optical fiber clamping device is arranged above the fiber dropping slot on the rack, and a fiber dropping feeding device is arranged between the optical fiber clamping device and the rack; and label attaching rollers are rotationally mounted on two sides below the fiber dropping slot on the rack respectively, an elastic extrusion rolling layer is arranged on the rolling surface of each label attaching roller, and the distance between the nearest points of the two elastic extrusion rolling layers is smaller than the diameter of a jumper. In the downward feeding process of the jumper, the label stickers are continuously gathered and adhered, automatic labeling is formed, automatic labeling operation is achieved, labeling efficiency is improved, labeling quality is ensured, and the production cost is reduced.

Owner:SHANGHAI HUIJUE NETWORK COMM EQUIP

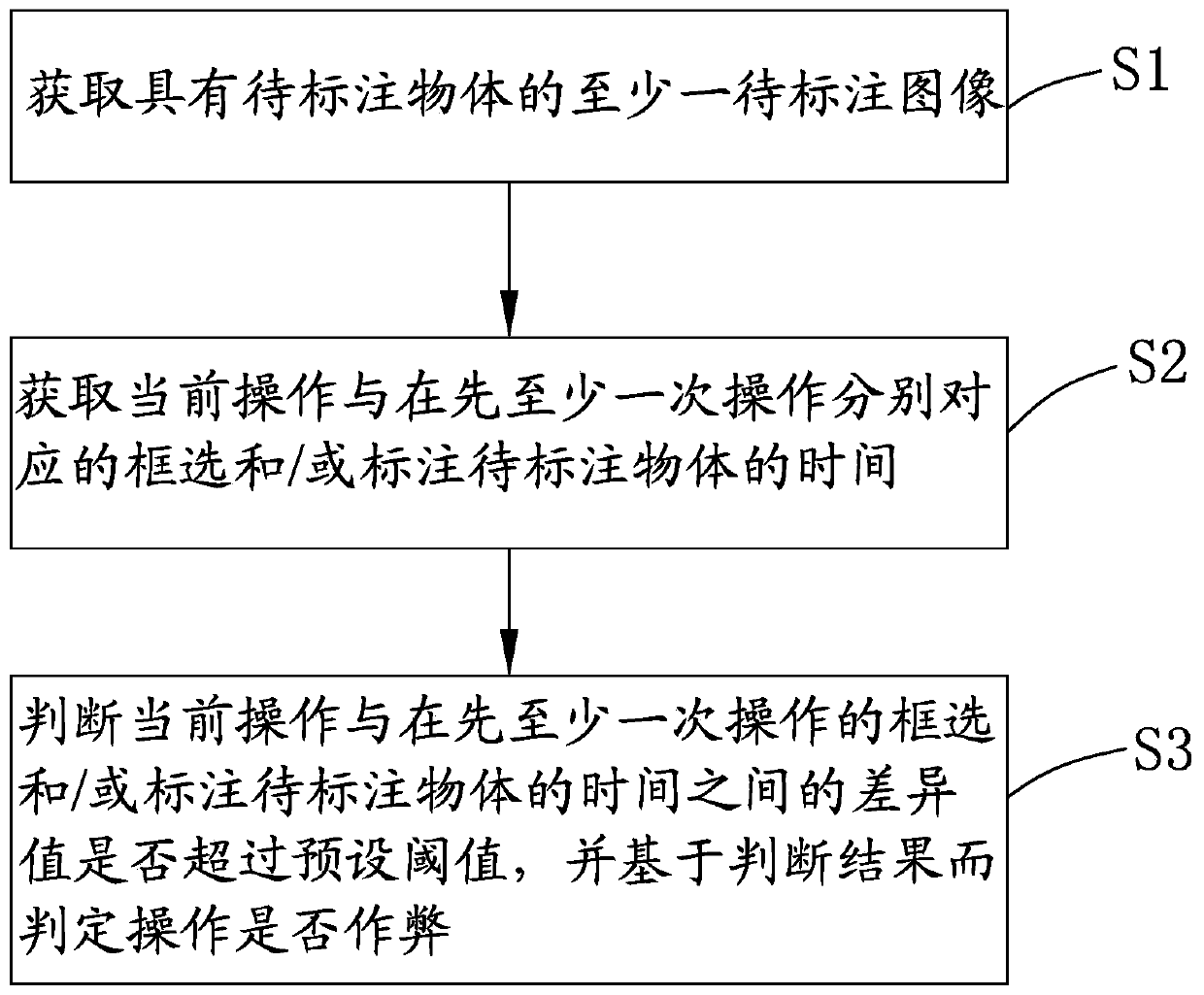

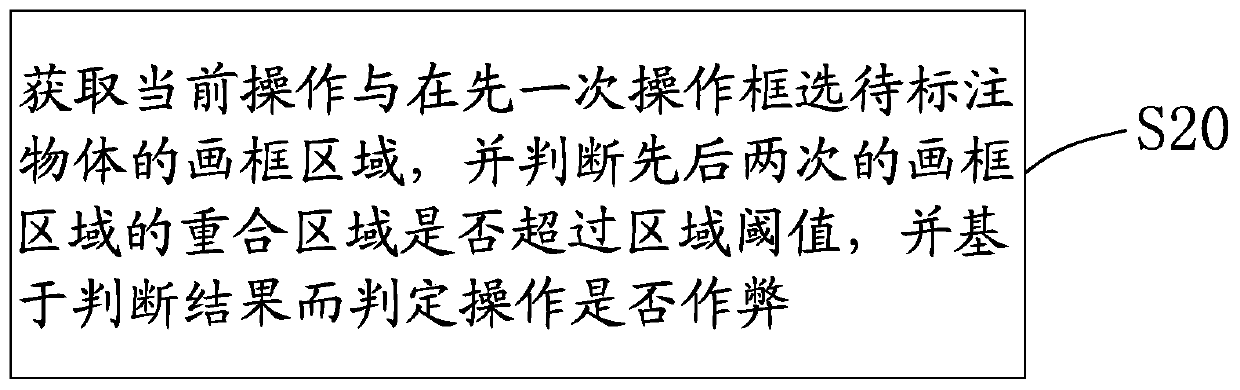

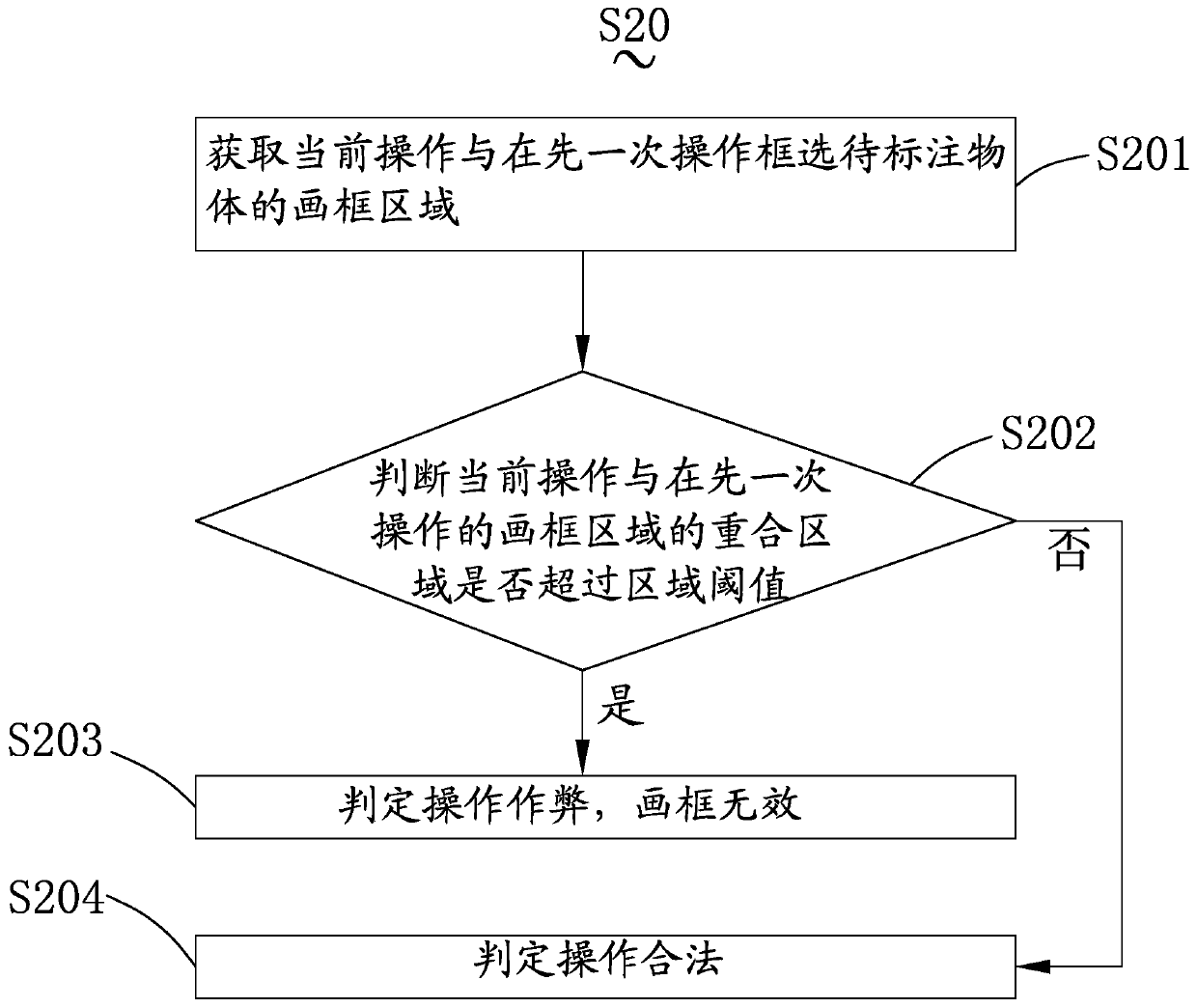

Anti-cheating method and system for image annotation and electronic equipment

InactiveCN110348507AGuaranteed labeling qualityIncrease binding forceCharacter and pattern recognitionSimulationAnnotation

The invention provides an anti-cheating method for image annotation. The anti-cheating method comprises the steps: obtaining at least one to-be-annotated image with a to-be-annotated object; and obtaining the frame selection time of the current operation and the to-be-annotated object selected by the previous operation for at least one time and the annotation time of the to-be-annotated object, judging whether the frame selection time and the annotation time of the current operation and the previous operation for at least one time exceed preset thresholds or not, and judging whether the operation is cheating or not based on a judgment result. By judging whether two times of frame selection time and annotation time exceed a preset threshold value or not, the method anti-cheating determineswhether cheating occurs is determined, and improves the constraint force for employee operation, so as to avoid the problems that the employee repeatedly carries out picture frame and repeatedly selects picture annotation on the same to-be-annotated object or characteristic, thus guaranteeing annotation quality of image annotation, and reducing time and investment cost caused by cheating problems.

Owner:创新奇智(南京)科技有限公司

A pressing device applied to a labeling machine

ActiveCN106428873BEliminate warped edgesGuaranteed labeling qualityLabelling machinesBottlePiston rod

The invention discloses a press covering device applied to a labeling machine. A left supporting seat and a right supporting seat are fixed at two sides of a supporting plate of the press covering device respectively; a horizontal spreading roll and a press roll are arranged between the left supporting seat and the right supporting seat; two ends of the spreading roll or the press roll are both hinged on a side bracket, and the side bracket is fixed on the supporting plate; a turntable is hinged on the inner wall of the left supporting seat; a sleeve body is formed on the outer wall of the right supporting seat; a slide block is inserted into the sleeve body; a horizontal push cylinder is fixed on the outer side wall of the sleeve body; a piston rod of the push cylinder penetrates through the sleeve body and is fixed on the slide block; a clamped cylinder is fixed on the slide block; a stud is formed at the top of a piston rod of the clamped cylinder; a pipe sleeve sleeves on the piston rod of the clamped cylinder by inserting; an end cap sleeves on the piston rod of the clamped cylinder at the front end of the pipe sleeve by inserting; a nut is in threaded connection with the stud at the front side of the end cap; and the end cap presses against the nut. The press covering device disclosed by the invention is simple in structure, can be used for performing press fit treatment on a label on a bottle body, and can eliminate a condition of edge warping of the label during labeling, thereby ensuring the labeling quality of the labeling machine.

Owner:ZHEJIANG AXILONE SHUNHUA ALUMINUM IND

A mobile phone case accessories labeling machine

ActiveCN106005640BIncrease productivityGuaranteed labeling qualityLabelling machinesControl systemEngineering

The invention provides a mobile phone shell accessory labeling machine, and belongs to the field of manufacturing of mobile phones. The mobile phone shell accessory labeling machine comprises a worktable, at least one labeling device respectively arranged on the worktable for labeling mobile phone shells, a carrying device for carrying the mobile phone shells on a upstream conveying line to the labeling device and carrying the mobile phone shells labeled on the labeling device to a downstream conveying line, and a control system for controlling the carrying device and the labeling device. Compared with the prior art, the mobile phone shell accessory labeling machine can be synchronously provided with at least one labeling device on the worktable, and the mobile phone shells carried by the carrying device pass through each labeling device on the worktable for automatic labeling, so that the production efficiency is improved, the labeling quality is guaranteed, and the manufacturing and labor costs are reduced.

Owner:领益智造科技(东莞)有限公司

Beef chili sauce bottle body packaging and labeling device

PendingCN112874963AFast labeling actionGuaranteed labeling speedLabelling machinesElectric machineryEngineering

The invention relates to the technical field of packaging and labeling, and discloses a beef chili sauce bottle body packaging and labeling device which comprises a mounting plate. A conveying rail is arranged at the top of the mounting plate, a limiting plate is arranged above the conveying rail, a servo motor located on the front face of the conveying rail is arranged at the top of the mounting plate, and the output end of the top of the servo motor is fixedly connected with a first rolling shaft through a rotating shaft. According to the device, the effect of effectively and rapidly controlling a pressing plate to move front and back is achieved through a first air cylinder, the effect of rapidly conducting the labeling action is achieved, a stepping motor is started to enable a driving screw to rotate, rotation of the driving screw enables a threaded plate to pull the pressing plate to move front and back under limiting of a limiting rod, and therefore the labeling action effect is realized at high precision through thread transmission, the labeling speed is guaranteed through the first air cylinder, the labeling precision is guaranteed through thread transmission, and the effects that the labeling work can be rapidly carried out, and the labeling quality can be guaranteed are achieved.

Owner:甘肃张小婉食品有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com