Automatic labeling mechanism and method for label paper

A technology of label paper and floating mechanism, which is applied in labeling machines, labels, packaging, etc., can solve the problems of ineffective attachment of labels and electric meters, complex movement mechanisms, etc., to achieve precise alignment, high fault tolerance, and guaranteed The effect of labeling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

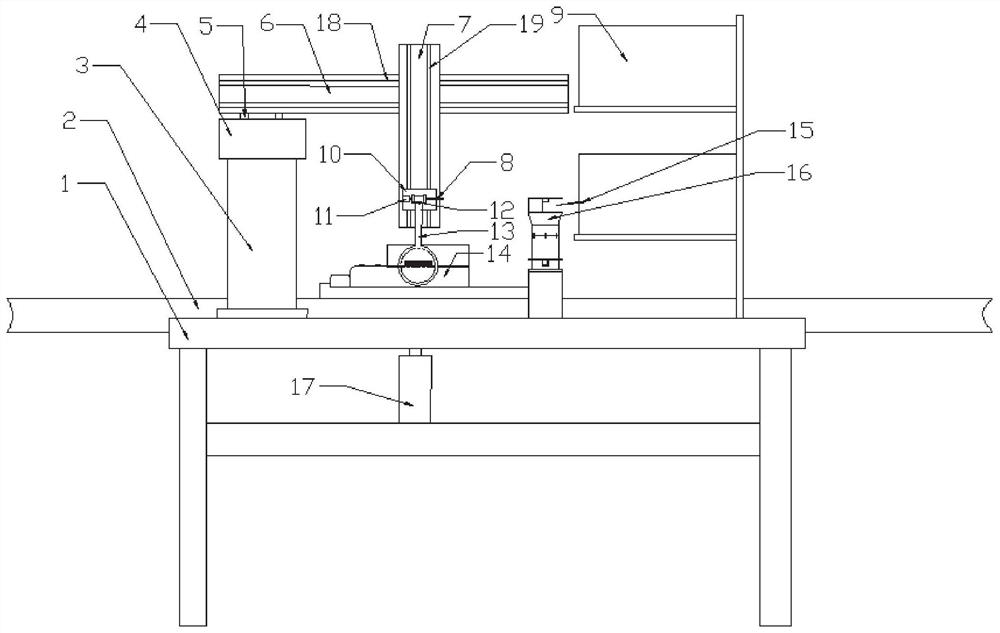

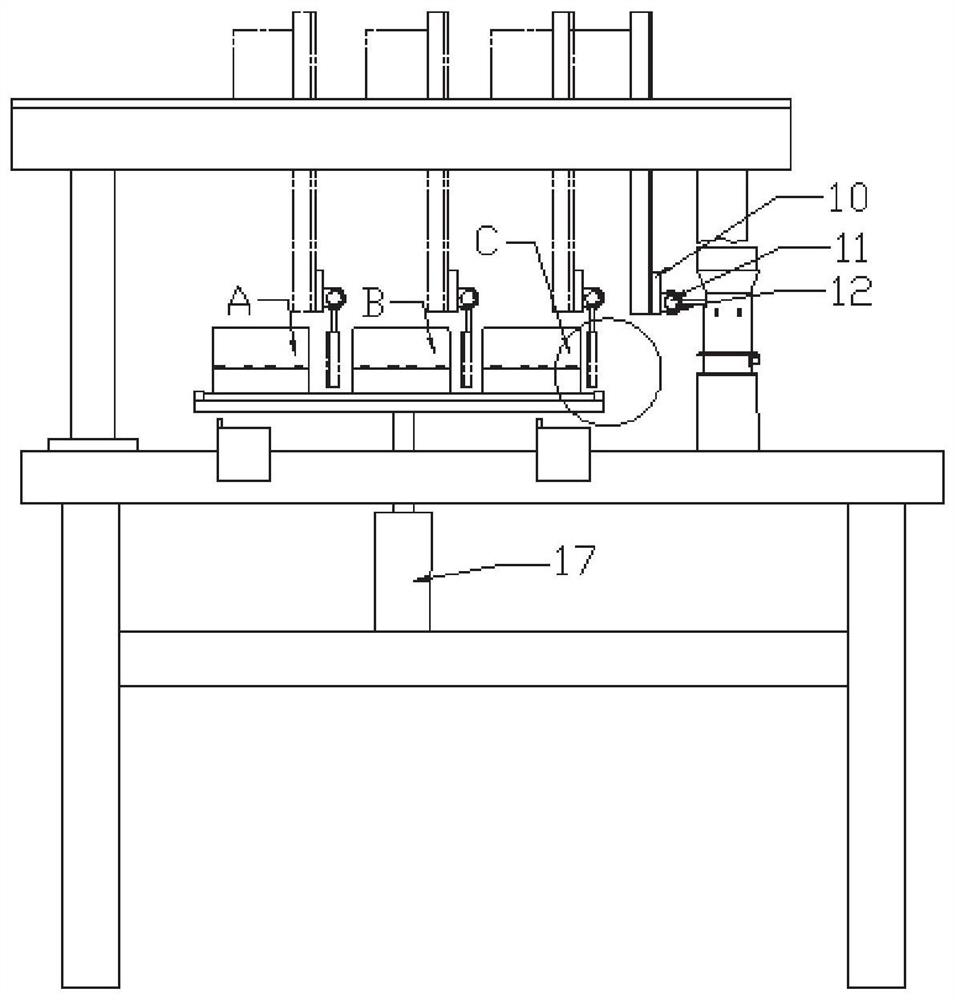

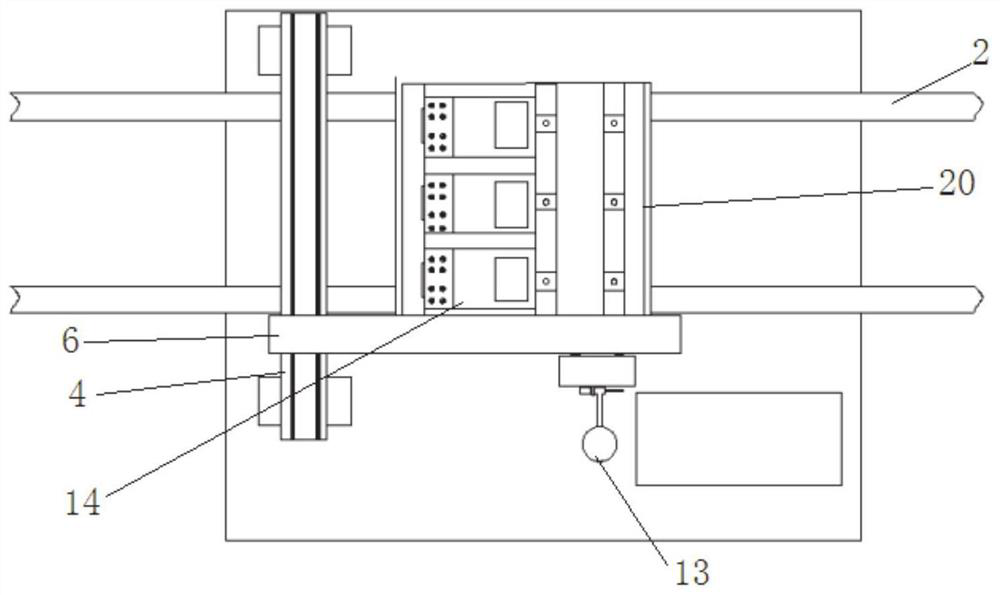

[0037] This embodiment provides an automatic labeling mechanism for label paper, such as Figure 1-Figure 3 As shown, it includes an adsorption plate 13, a floating mechanism, a three-axis moving mechanism, a workbench 1, and a label printer 9. The three-axis movement mechanism is installed on the workbench 1, and the adsorption plate 13 is rotationally connected with the three-axis movement mechanism; the workbench 1 Install the printer 6 on the side opposite to the three-axis moving mechanism, and the floating mechanism corresponds to the outlet position of the label printer 9.

[0038] The label printer 9 adopts an existing printer structure for printing label paper 15, wherein one side of the label paper 15 is an adhesive surface, and the other side is a non-adhesive surface.

[0039] Further, an ammeter tray 20 is arranged above the workbench 1, and a plurality of ammeters 14 are arranged on the ammeter tray 20, which are moved to the side of the ammeter tray 20 through t...

Embodiment 2

[0052] This embodiment provides a method for automatic labeling of label paper, using the labeling mechanism described in Embodiment 1, comprising the following steps:

[0053] S1: In the initial state, under the action of the three-axis moving mechanism, the adsorption plate 13 is located outside the casing 16, the controller controls the label printer 9 to print the label paper 15, and the printed label paper 15 enters the casing through the feeding port 168 In body 16.

[0054] S2: After the printing work is completed, after a certain period of time, the controller controls the blower 163 to start, and the blower 162 moves the label paper 15 upward. Between the second exhaust holes 166, the controller controls the three-axis moving mechanism to drive the adsorption plate 13 to move.

[0055] In this embodiment, after the label paper 15 enters the housing 16, under the action of the photoelectric receiver 161 and the photoelectric transmitter 164, it is detected that the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com