Locating pneumatic pressing apparatus for square lithium ion and nickel-hydrogen battery label

A nickel-metal hydride battery and lithium ion technology is applied in the field of battery labeling devices, which can solve the problems of difficult to guarantee labeling quality, low production efficiency, and easy to skew when pleating, so as to ensure labeling quality, improve production efficiency, and reduce labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

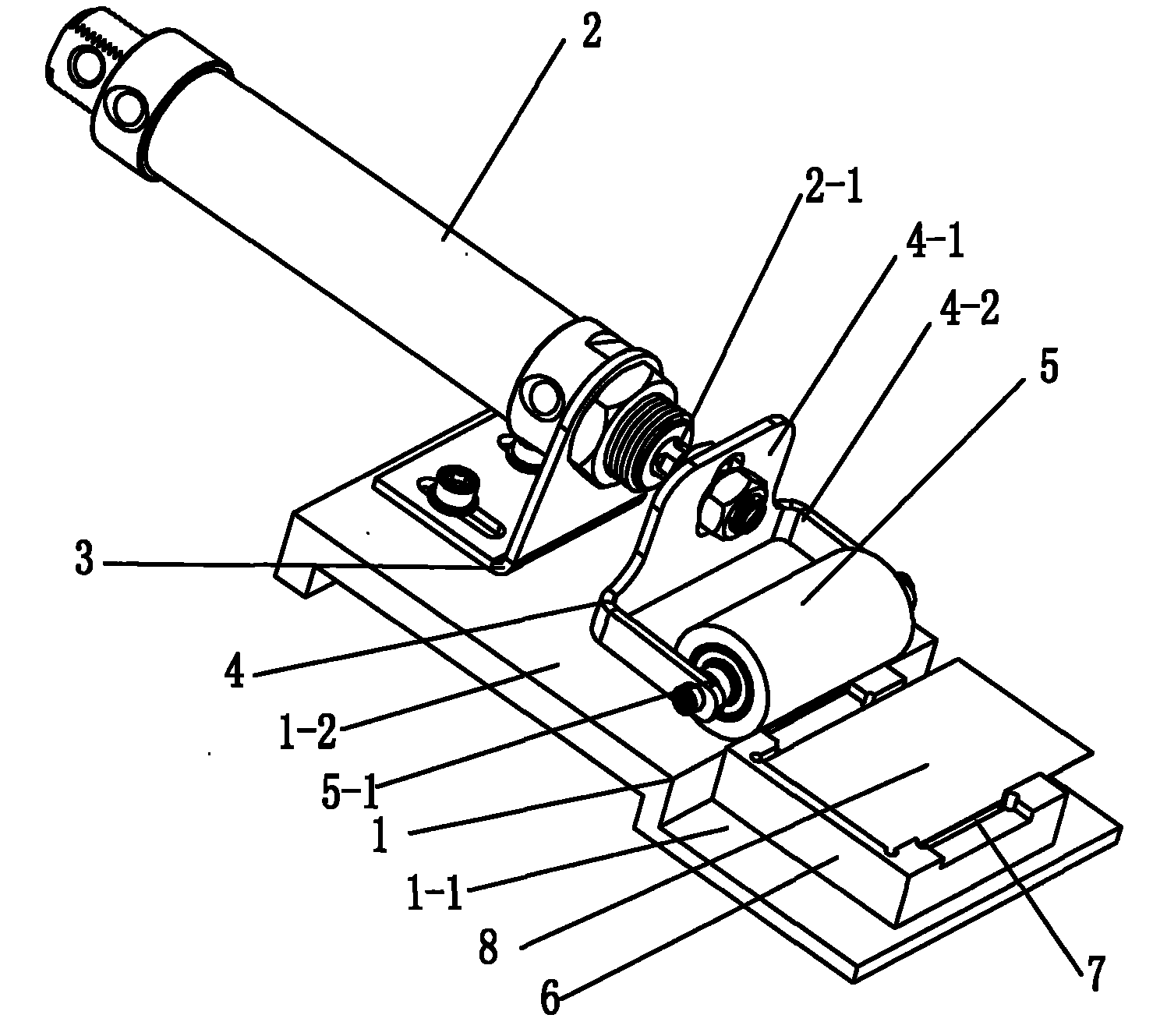

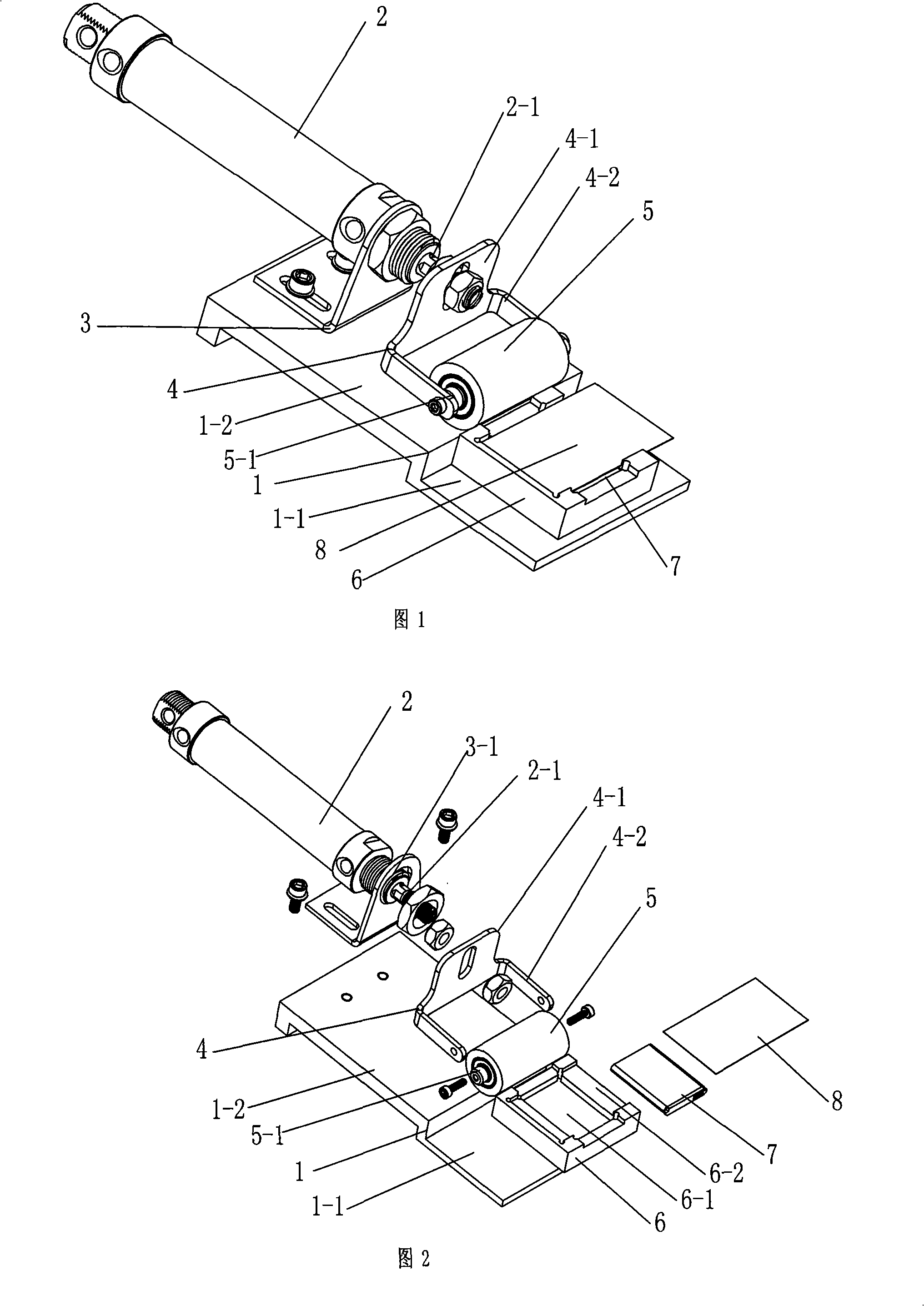

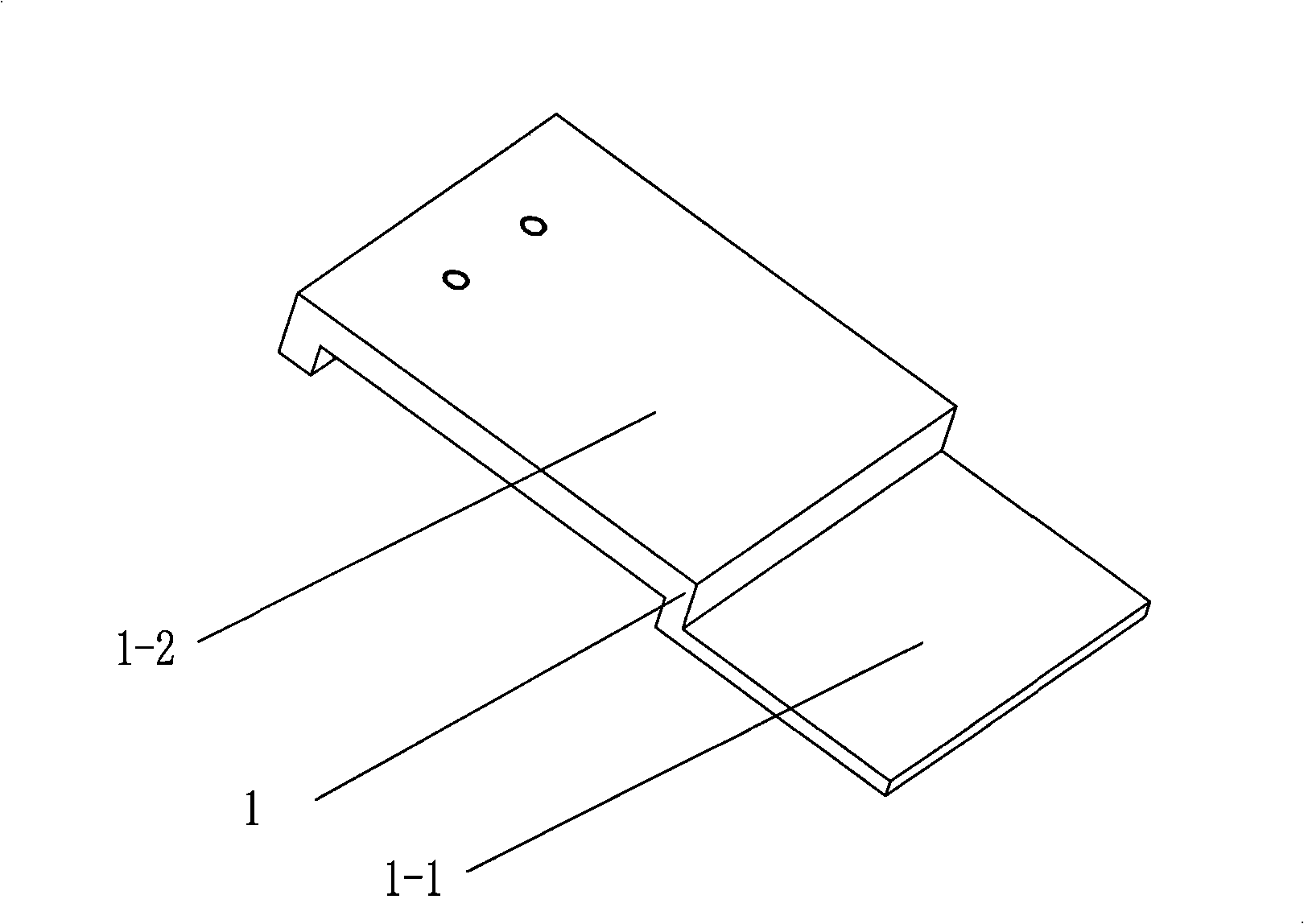

[0008] Specific embodiment 1: This embodiment is described in conjunction with Fig. 1 to Fig. 8. This embodiment consists of a stepped base 1, a cylinder 2, an L-shaped cylinder support 3, a pressure roller assembly support 4, a pressure roller assembly 5, and a double positioning mold 6 , a battery 7 and a product label 8, the press roller assembly bracket 4 is composed of a vertical arm 4-1 and two cross arms 4-2, and the two cross arms 4-2 are respectively located at the lower end of the vertical arm 4-1 The two sides of the double positioning mold 6 are integrated with the vertical arm 4-1. There are two positioning grooves on the upper end surface of the double positioning mold 6, and the two positioning grooves are respectively the battery positioning groove 6-1 and the commodity label positioning groove 6. -2, the difference between the depth of the battery positioning groove 6-1 and the depth of the product label positioning groove 6-2 is the thickness of the battery 7,...

specific Embodiment approach 2

[0009] Specific embodiment two: This embodiment is described in conjunction with FIG. 7. The pressure roller assembly 5 of this embodiment is composed of a shaft 5-1, two bearings 5-2, a pressure roller 5-3 and a soft material layer 5-4. The two ends of the pressure roller 5-3 are respectively sleeved on the shaft 5-1 through corresponding bearings 5-2, and the soft material layer 5-4 is pasted on the surface of the pressure roller 5-3. With this setting, the labeling quality is better. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Embodiment 3: This embodiment is described with reference to FIG. 7 . The soft material layer 5 - 4 of the pressure roller assembly 5 of this embodiment is a kapok glue layer. With this setting, the labeling quality is better. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com