Beef chili sauce bottle body packaging and labeling device

A beef chili sauce and bottle technology, which is applied in packaging, labeling machine, transportation and packaging, etc., can solve the problems affecting the packaging and labeling work of beef chili sauce bottle body, single structure, and inability to promote fast and high precision at the same time, etc. Achieve the effect of improving labeling quality, ensuring stability, and improving labeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

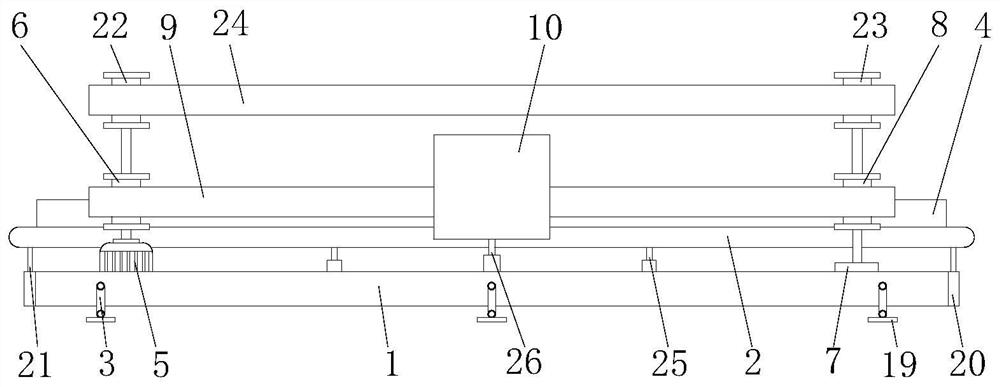

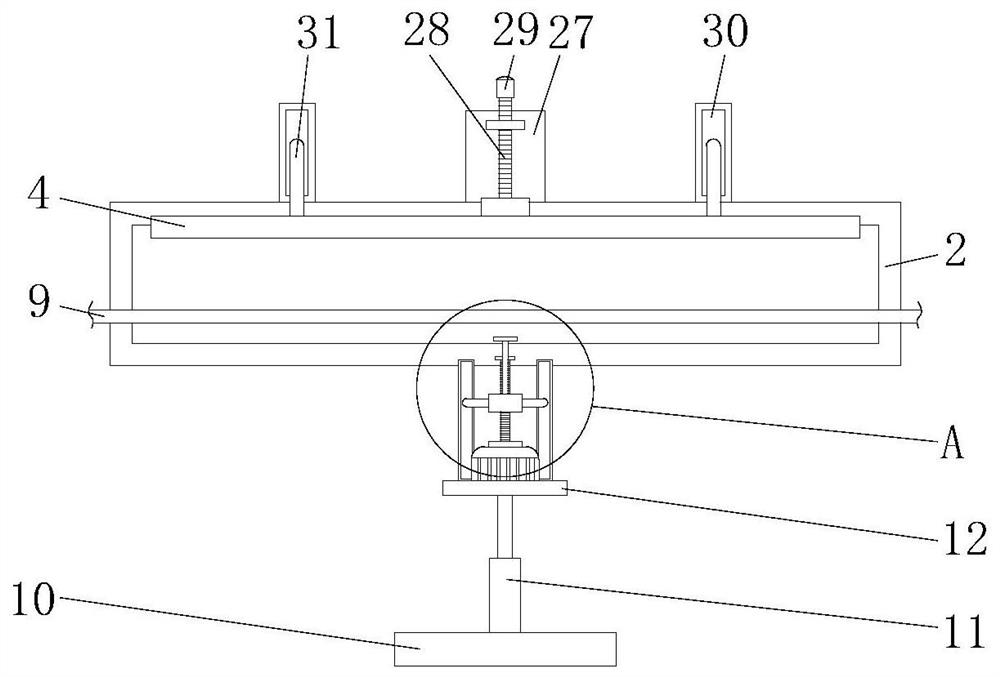

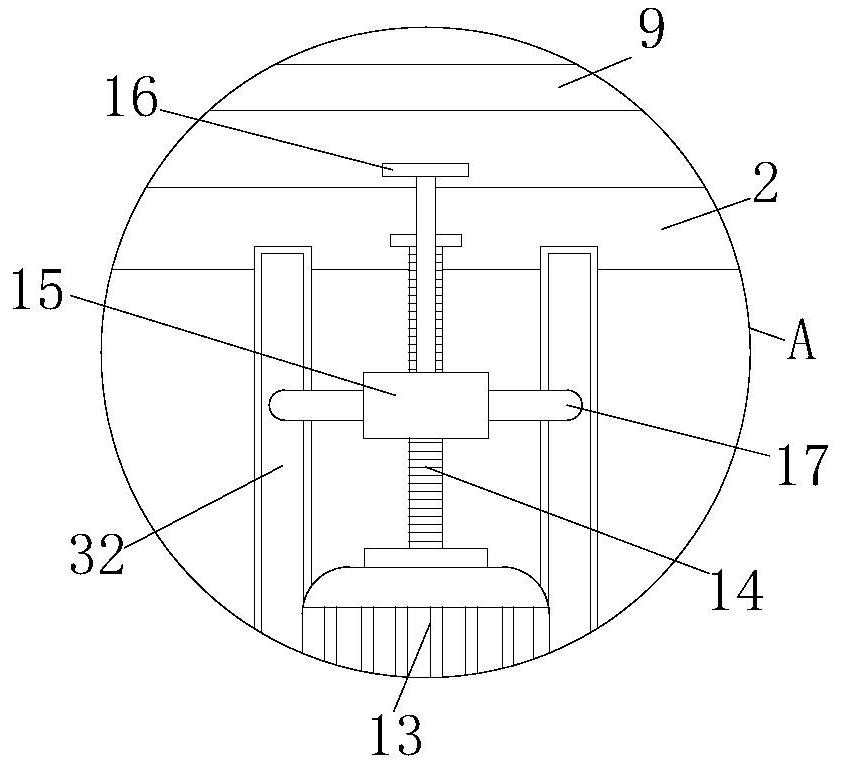

[0028] refer to Figure 1-3 , a beef chili sauce bottle packaging labeling device, comprising a mounting plate 1, the top of the mounting plate 1 is provided with a conveying track 2, the top of the conveying track 2 is provided with a limiting plate 4, the top of the mounting plate 1 A servo motor 5 positioned on the front of the conveying track 2 is provided, the connection between the mounting plate 1 and the servo motor 5 is a screw connection, the output end of the top of the servo motor 5 is fixedly connected with a first roller 6 through a rotating shaft, The top of the mounting plate 1 is fixedly connected with an installation bearing seat 7 located on the right side of the servo motor 5, and the inner surface of the top of the installation bearing seat 7 is fixedly connected with a second roller 8, and the first roller 6 and The outer surface of the second roller 8 is connected through the transmission of the labeling roll 9, the top of the mounting plate 1 is provide...

Embodiment 2

[0030] Such as Figure 1-4 As shown, the front and the back of the mounting plate 1 are connected with a stabilizing bar 3 through a first hinge, and one end of the stabilizing bar 3 away from the mounting plate 1 is rotatably connected with a stabilizing plate 19 through a second hinge. 3 The side close to the mounting plate 1 is fixedly connected to the surface of the mounting plate 1 through a connecting spring 18, the length of the connecting spring 18 is not less than five centimeters, and the elastic coefficient of the connecting spring 18 is 30 Newtons per centimeter. The left and right sides of mounting plate 1 are all provided with guide tube 20, and the bottom of described delivery track 2 is provided with guide bar 21, and the bottom end of described guide bar 21 extends in guide tube 20, and described delivery track 2 and guide bar The connection between 21 is welding, the top of the first roller 6 is fixedly connected with the third roller 22, the top of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com