Automatic labeling machine and labeling method

A labeling machine and automatic technology, applied in labeling machines, labels, packaging, etc., can solve problems affecting product labeling quality and insufficient labeling stability, so as to improve labeling quality, ensure labeling quality, and improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

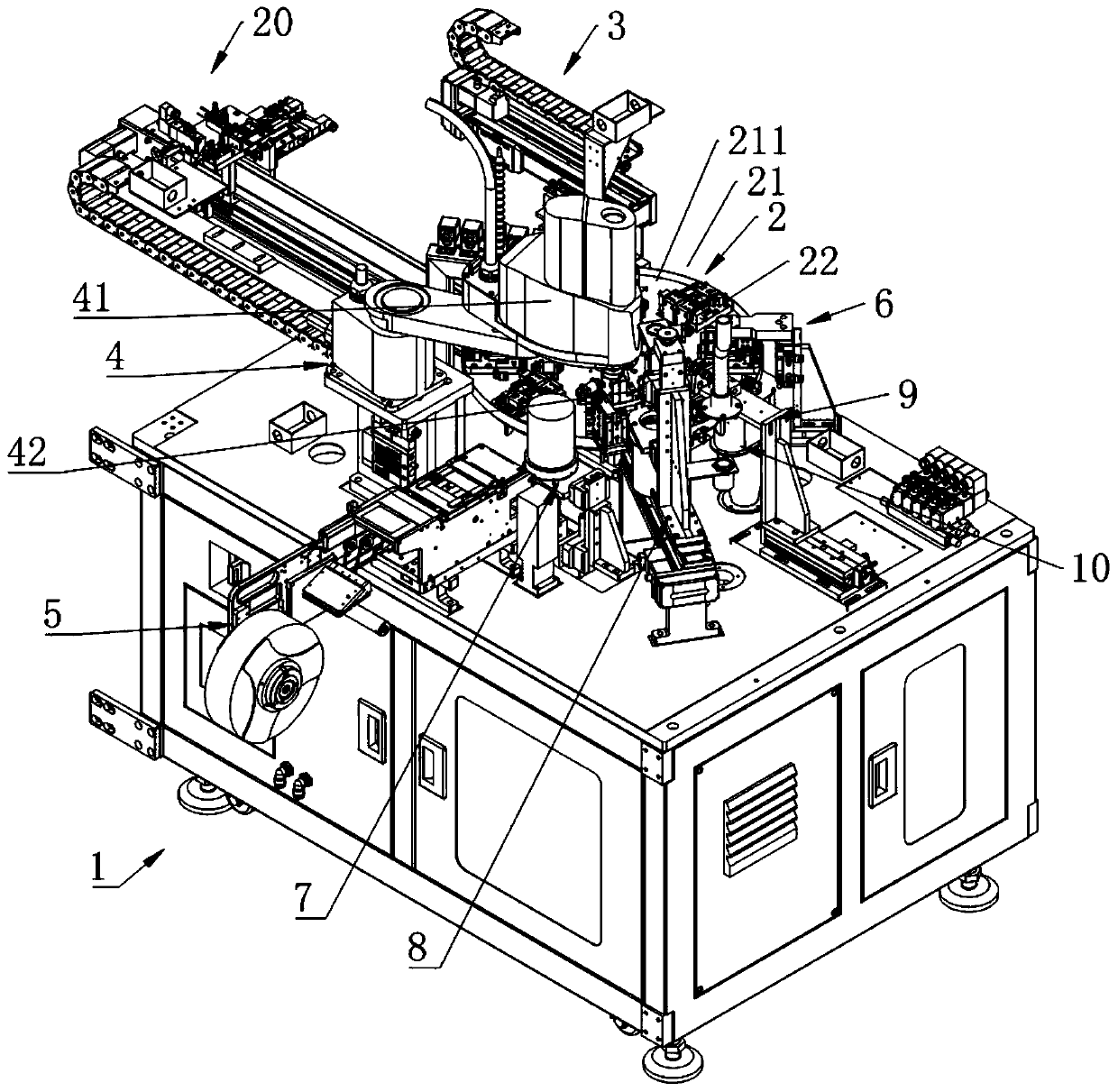

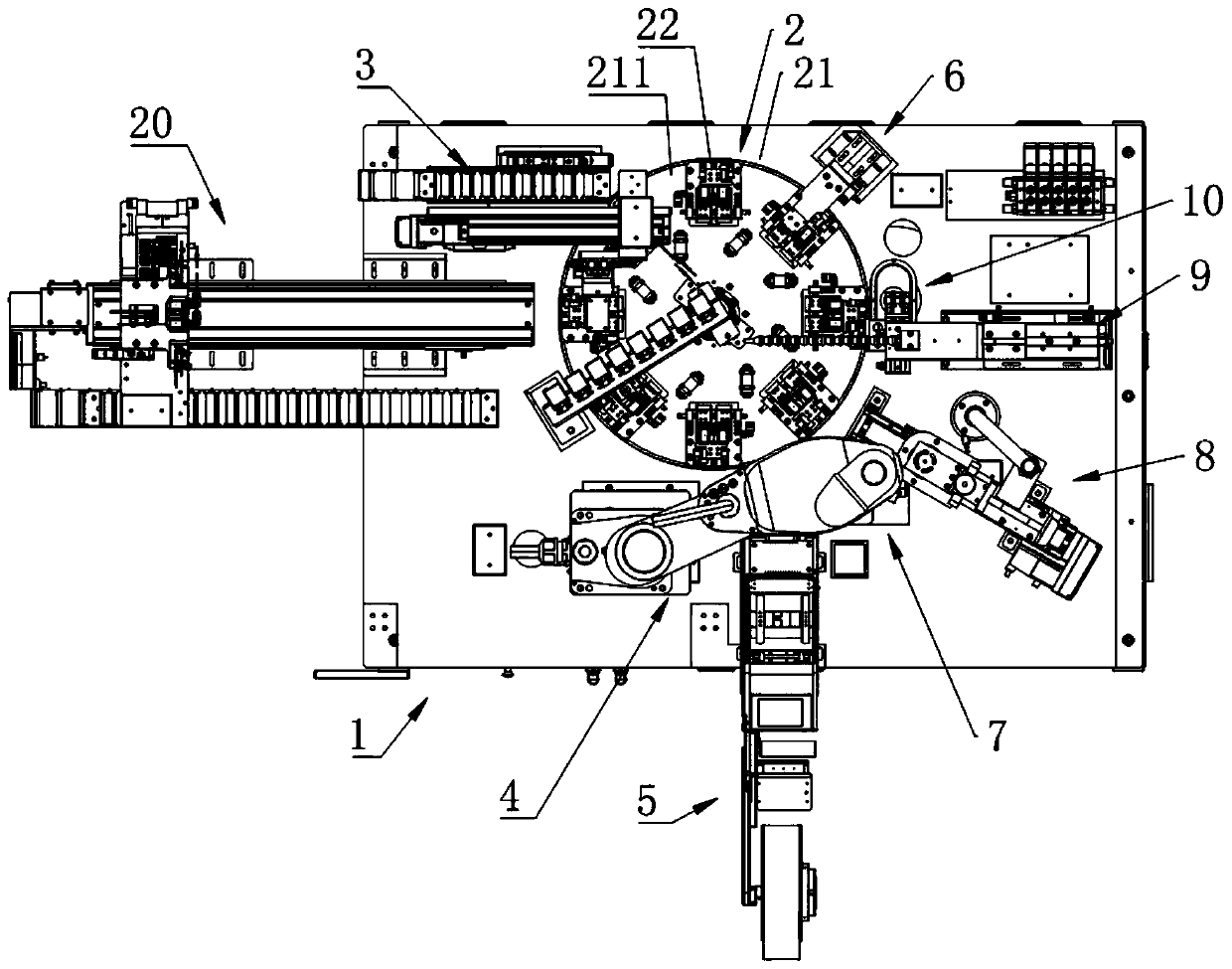

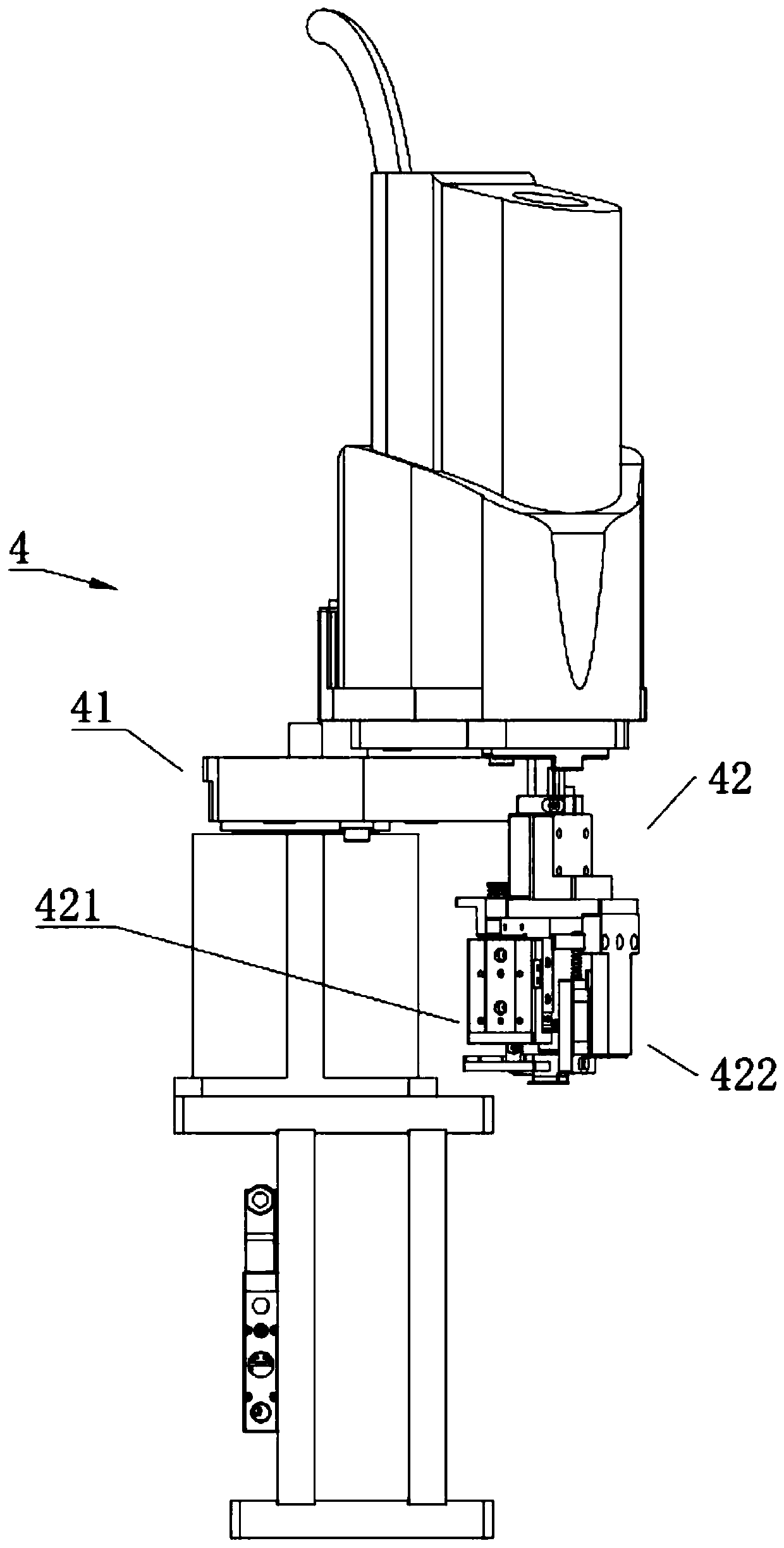

[0039] refer to figure 1 with figure 2 , figure 1 It is the structural representation of the automatic labeling machine in embodiment one, figure 2 It is a structural schematic diagram of another perspective of the automatic labeling machine in the first embodiment. The automatic labeling machine in this embodiment includes a frame 1 , a carrier turntable device 2 , a feeding device and a labeling device 4 arranged on the frame 1 . The feeding device and the labeling device 4 are sequentially arranged around the rotation direction of the carrier turntable device 2 . The feeding device is used for feeding products and labels. The carrier turntable device 2 is used to transmit the loaded products through the labeling device 4. The labeling device 4 receives the loaded labels and attaches the labels to the products. , and roll the attached standard parts.

[0040] The labeling device first attaches the label to the product and then rolls and reinforces it, so that the labe...

Embodiment 2

[0061] persistent reference Figure 13 , Figure 13 It is a flowchart of the labeling method in the second embodiment. The labeling method in the present embodiment is realized based on the labeling machine in the first embodiment, and it comprises the following steps:

[0062] S1, the feeding device loads the products and standard parts.

[0063] S2, the carrier turntable device 2 conveys the loaded product through the labeling device 4 .

[0064] S3, the labeling device 4 receives the supplied label and attaches the label to the product.

[0065] S4, the labeling device 4 rolls the attached label.

[0066] Attach the label to the product first, and then roll the attached label to make the label firmly on the product and ensure the labeling quality of the product.

[0067] Specifically, in step S1, the feeding device includes a first feeding device 3 and a second feeding device 5, and the first feeding device 3 and the second feeding device 5 respectively load products a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com