Shape-stabilized phase change energy storage material for building and preparation method thereof

A phase-change energy storage material and energy storage material technology, applied in the field of shaped phase-change energy storage materials for buildings and their preparation, can solve the problems of poor adsorption stability of shaped phase-change materials, lack of thermal conductivity of materials, and low preparation costs. Achieve the effects of good plasticity, good practicability and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

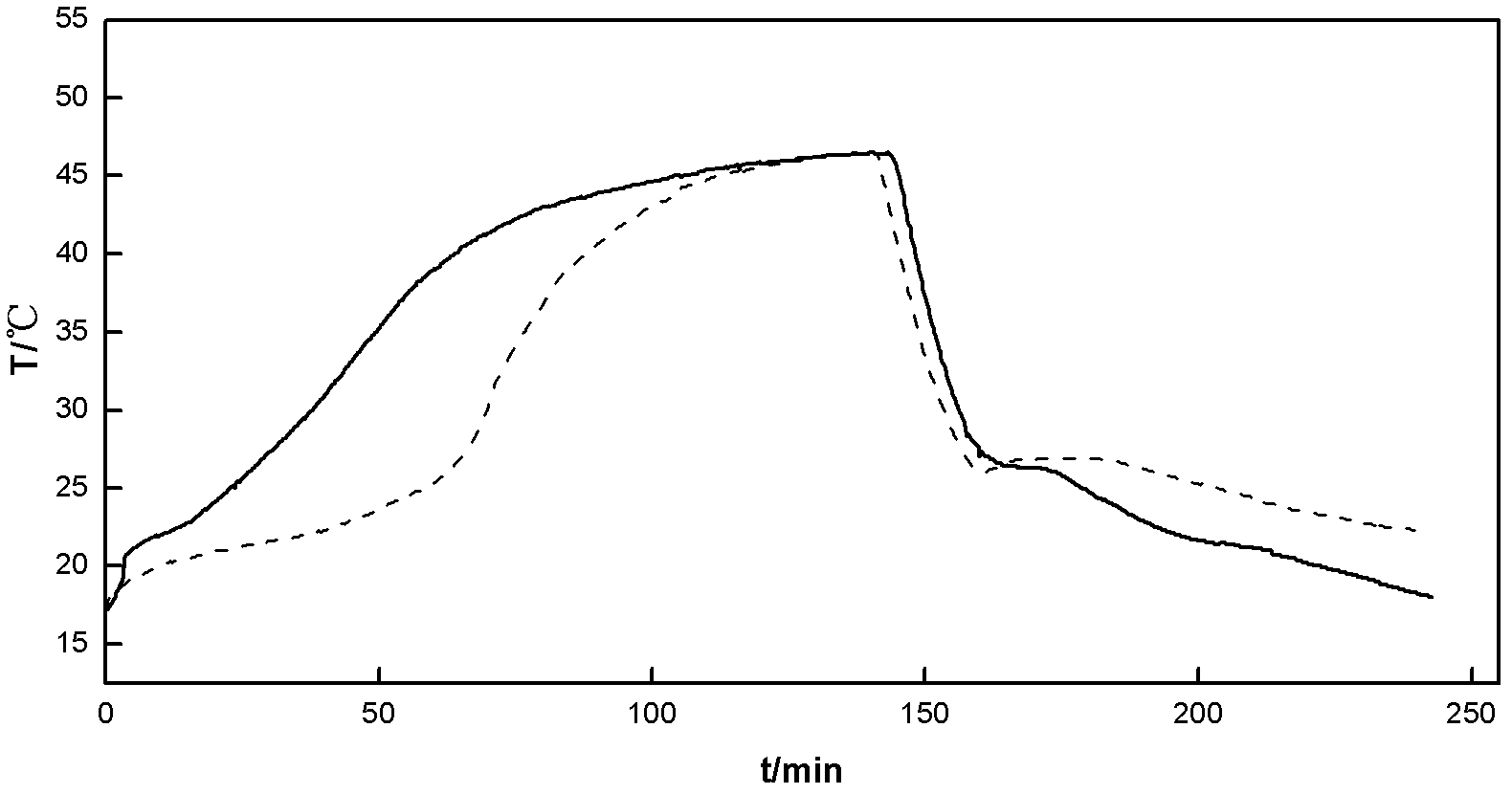

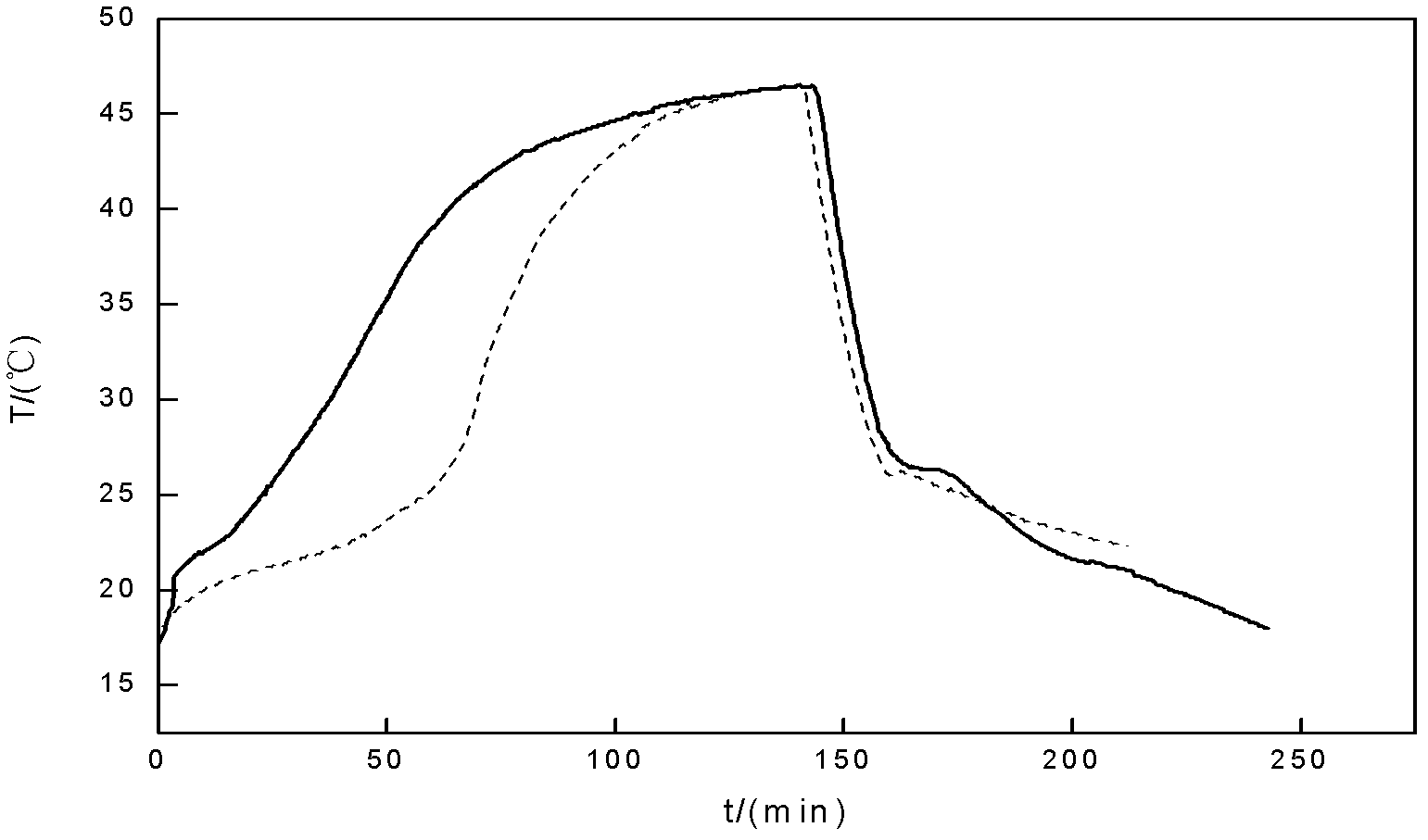

Embodiment 1

[0018] Using porous matrix fatty acid composite phase change energy storage materials and ordinary building gypsum powder (specific surface area 412m 2 / kg), to prepare shaped phase change energy storage materials for construction. In this example, the porous matrix is activated carbon powder, the molar ratio of the mixed phase change material is lauric acid:capric acid=6:4, the phase transition temperature is 25.1°C, the activated carbon powder (average particle size is 22 μm) fatty acid composite phase change storage The energy material is obtained by adding activated carbon powder into molten fatty acid at a temperature of 60°C, and fully mixing the activated carbon powder and molten fatty acid to obtain activated carbon powder fatty acid composite phase change energy storage material, and then adding ordinary building gypsum powder Prepare the shaped fatty acid phase change energy storage material by mixing with the composite phase change energy storage material. The ma...

Embodiment 2

[0020] Porous matrix fatty acid composite phase change energy storage materials and high-strength gypsum powder (specific surface area of 460m 2 / kg), to prepare shaped phase change energy storage materials for construction. In this embodiment, the porous matrix is activated carbon powder (average particle size 33 μm), the molar ratio of the mixed phase change material is lauric acid: capric acid = 5: 5, the phase transition temperature is 21.8 ° C, and the activated carbon powder fatty acid composite phase change energy storage The material is made by adding activated carbon powder into molten fatty acid at a temperature of 60°C, and then fully mixing the activated carbon powder and molten fatty acid to obtain an activated carbon powder fatty acid composite phase change energy storage material, and then adding high-strength gypsum powder and Composite phase change energy storage materials are mixed to prepare shaped fatty acid phase change energy storage materials. The m...

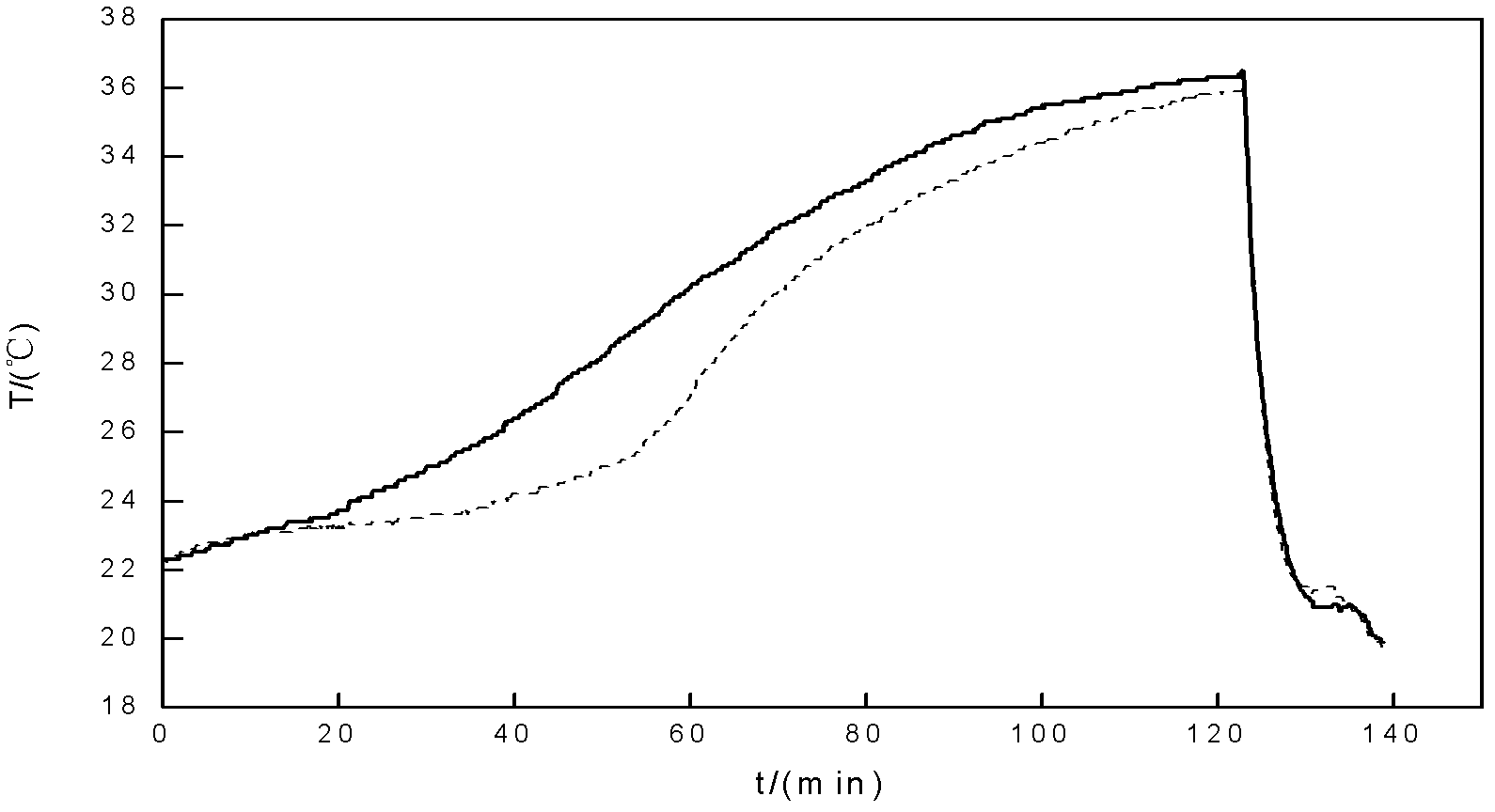

Embodiment 3

[0022] Using porous matrix fatty acid composite phase change energy storage materials and dihydrate gypsum powder (specific surface area 370m 2 / kg), to prepare shaped phase change energy storage materials for construction. In this example, the porous matrix is diatomite powder (average particle size 18 μm), the molar ratio of the mixed phase change material is lauric acid:capric acid=6:4, the phase transition temperature is 25.1°C, and the diatomite powder fatty acid compound The phase change energy storage material is made by adding diatomite powder into molten fatty acid at a temperature of 80°C, and then fully mixing the diatomite powder and molten fatty acid to obtain diatomite powder fatty acid composite phase change. The energy storage material is prepared by mixing the dihydrate gypsum powder and the composite phase change energy storage material to prepare the shaped fatty acid phase change energy storage material. The mass ratio of diatomaceous earth powder and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com