Lithium ion battery gel type ionic liquid/polymer electrolyte and preparation method thereof

A lithium-ion battery and ionic liquid technology, which is applied in the field of gel-type ionic liquid/polymer electrolyte and its preparation, can solve the problems of poor compatibility of negative electrode materials, and achieve the effects of good compatibility, low toxicity, and flexible packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

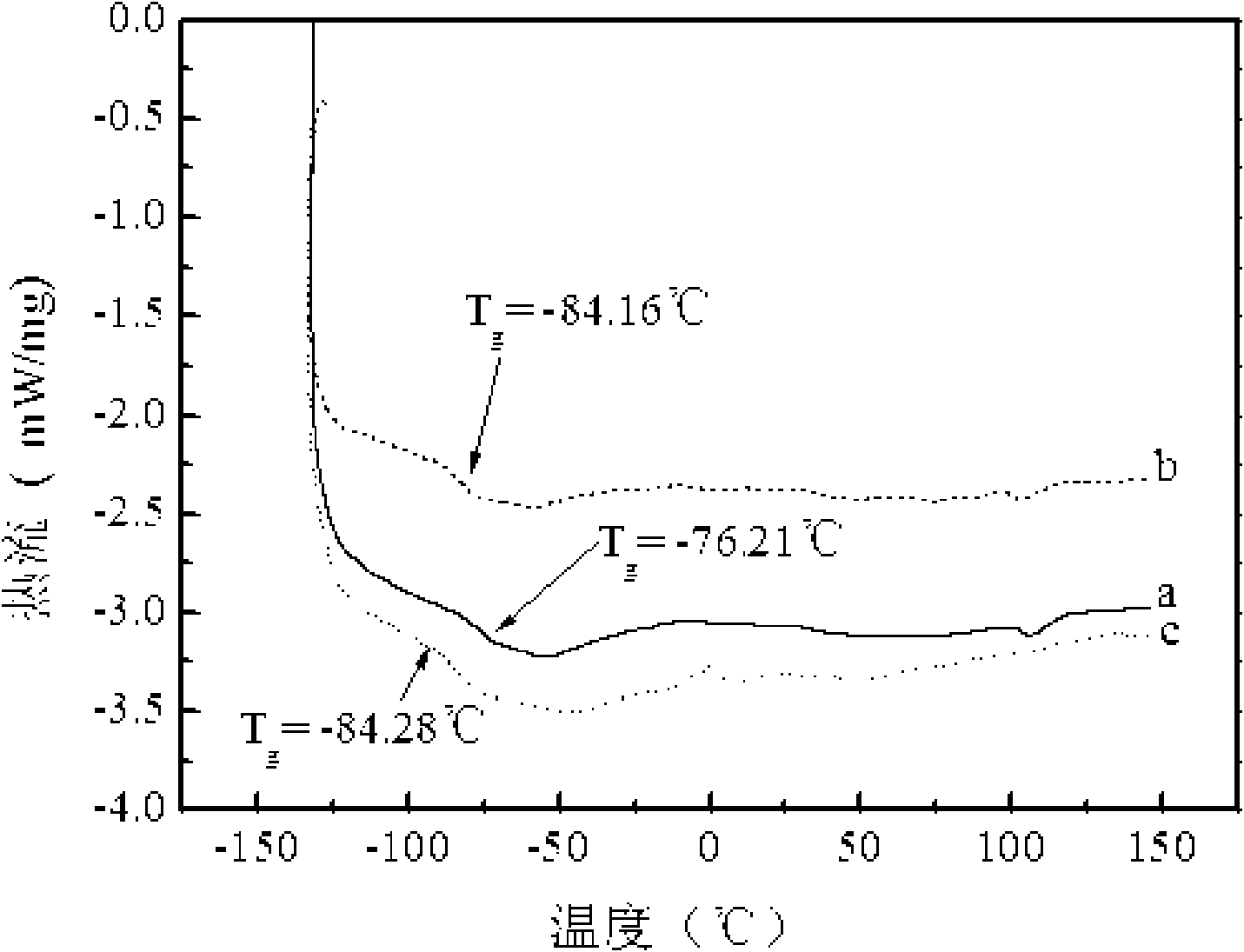

[0010] Specific embodiment one: In this embodiment, the gel-type ionic liquid / polymer electrolyte of the lithium-ion battery is made of a high molecular polymer, an imidazole ionic liquid and a lithium salt, wherein the mass ratio of the high molecular polymer to the imidazole ionic liquid is 1:1-2, the mass ratio of imidazole ionic liquid to lithium salt is 0.01-6:1.

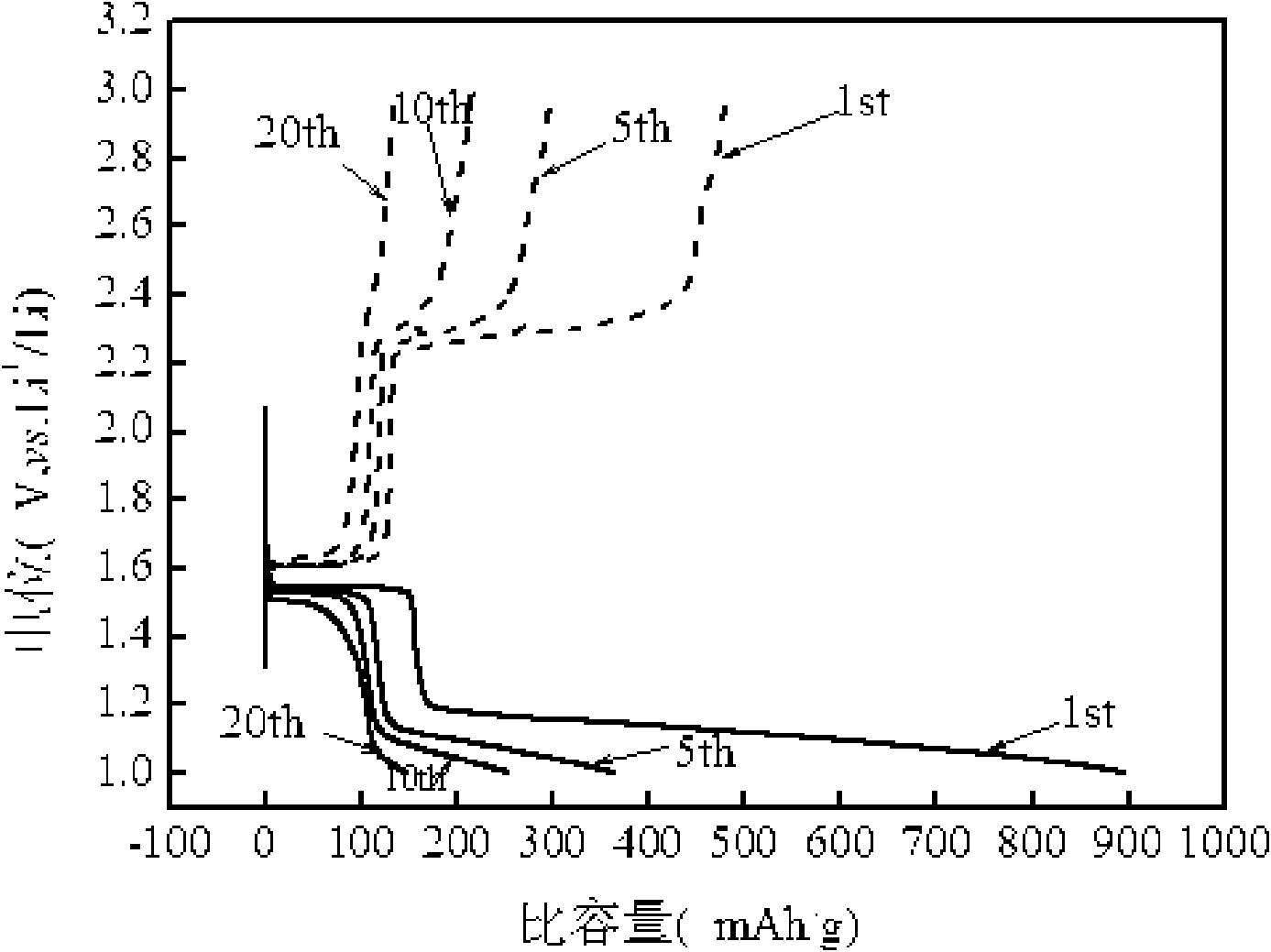

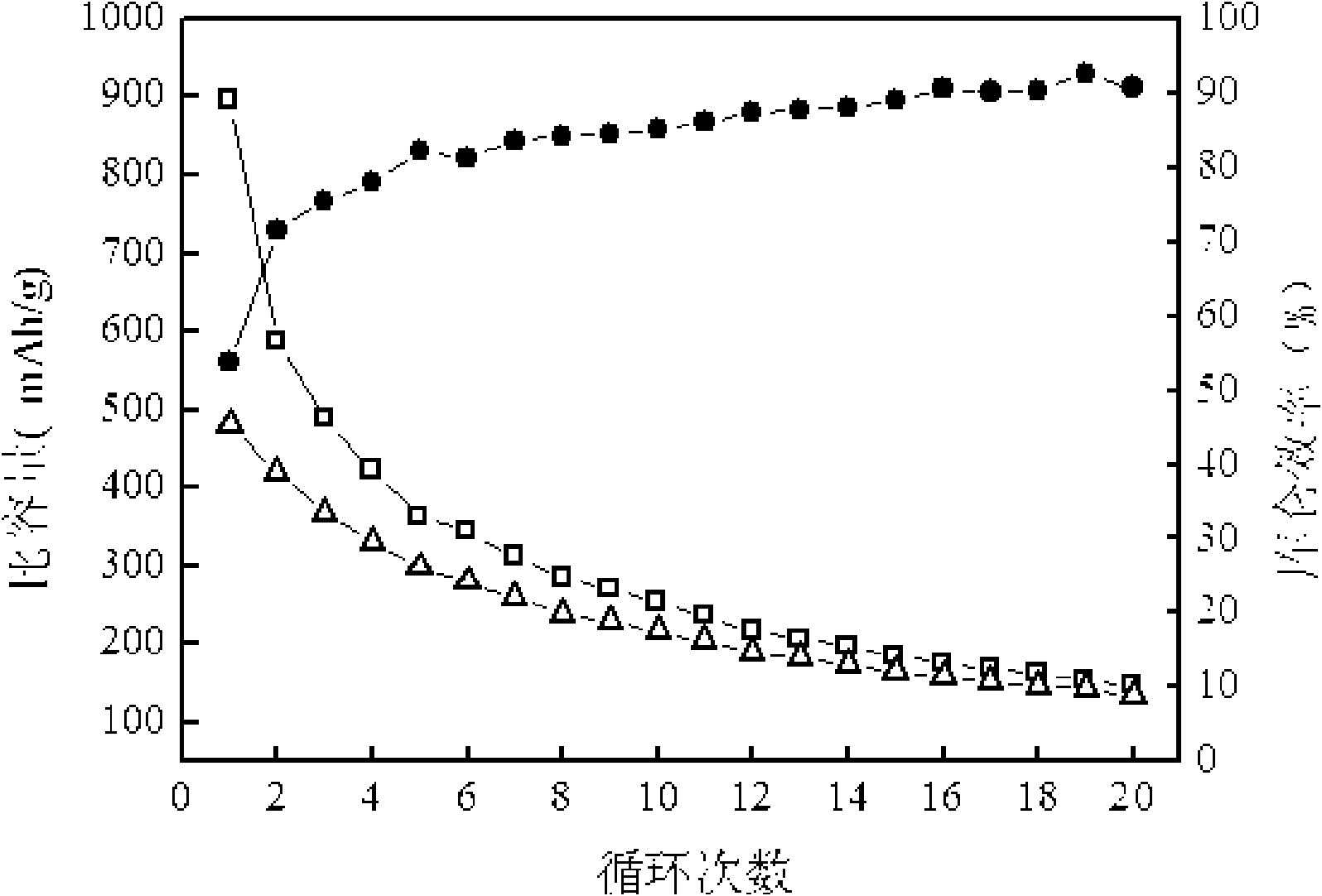

[0011] The ion conductivity of the electrolyte of the present embodiment is high, as high as 0.53×10 -3 S / m, good thermal stability and wide electrochemical stability window, it can be used in lithium-ion batteries with high capacity, and can also eliminate the safety hazards of liquid lithium-ion batteries to a large extent, and realize the battery's all-solid structure and residual liquid Minimal, encapsulating the purpose of flexibility. The electrolyte of the present embodiment has good compatibility with the lithium titanate negative electrode, and the lithium-ion battery manufactured with it has a first ...

specific Embodiment approach 2

[0012] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass ratio of the high molecular polymer to the imidazole-based ionic liquid is 1:1.2-1.8. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the mass ratio of the polymer to the imidazole ionic liquid is 1:1.5. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com