Waste tyre processing method

A technology for waste tires and a treatment method, applied in the field of rubber processing, can solve the problems of incomplete dry gas recovery, low product added value, waste of rubber resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

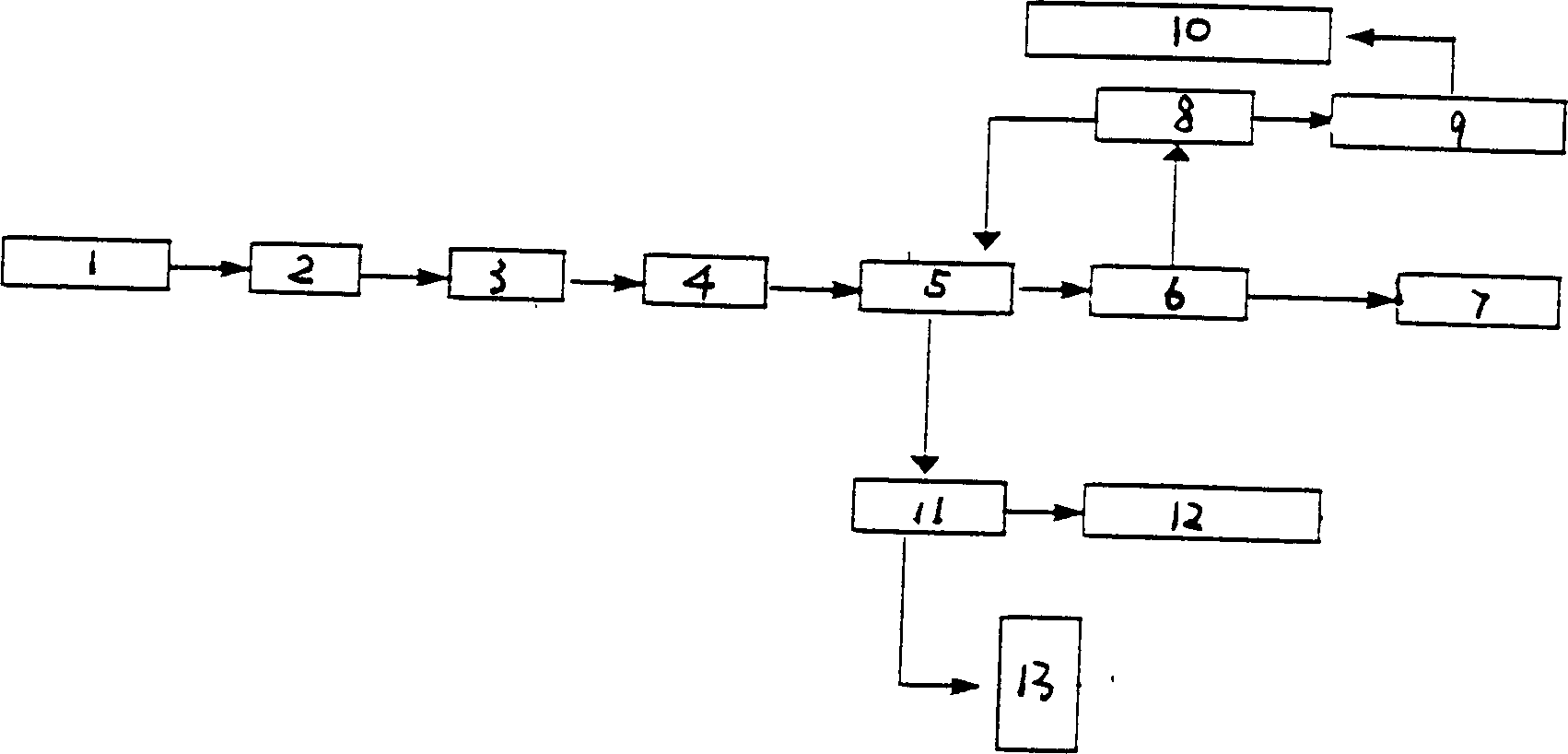

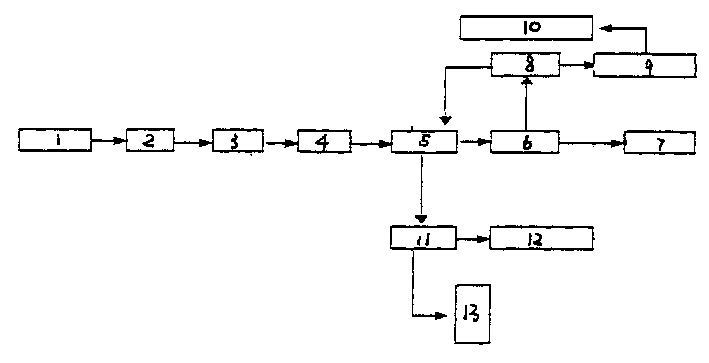

[0006] Such as figure 1 As shown, a treatment method for waste tires of the present invention includes three processes: tire crushing and slicing, thermal cracking treatment, and carbon black crushing and packaging. Crusher pre-crushing 2, then after washing 3 purification, then sent to the secondary crusher for secondary crushing 4 processing into colloidal particles with a diameter of less than 25 mm, the thermal cracking treatment process is to use the thermal cracking technology in the prior art , including transporting the colloidal particles obtained in the previous process to the thermal cracking furnace for thermal cracking 5, the colloidal particles are thermally cracked at 480-700 degrees Celsius and a slight negative pressure of 0.01-0.04 MPa, and the gas phase products enter the washing tower to condense Cooling 6, the obtained fuel oil is sent to the tank area for storage 7, and the uncondensed light components (hydrocarbon gas phase below C5) are recovered as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com