Methods for manufacturing and mounting prefabricated wall members

A technology of prefabricated walls and manufacturing methods, applied in the direction of supply devices, unloading devices, manufacturing tools, etc., can solve the problems of low construction efficiency, high energy consumption, and difficult management, and achieve the improvement of cement slurry leakage and simplify the process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

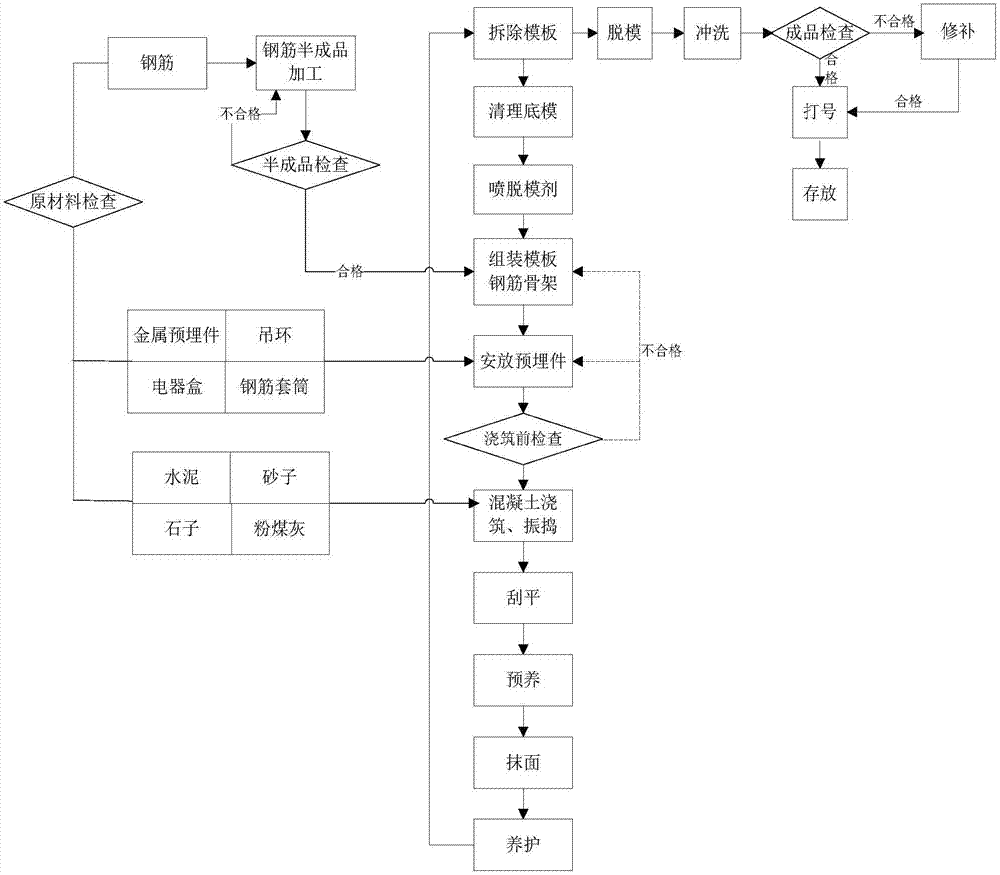

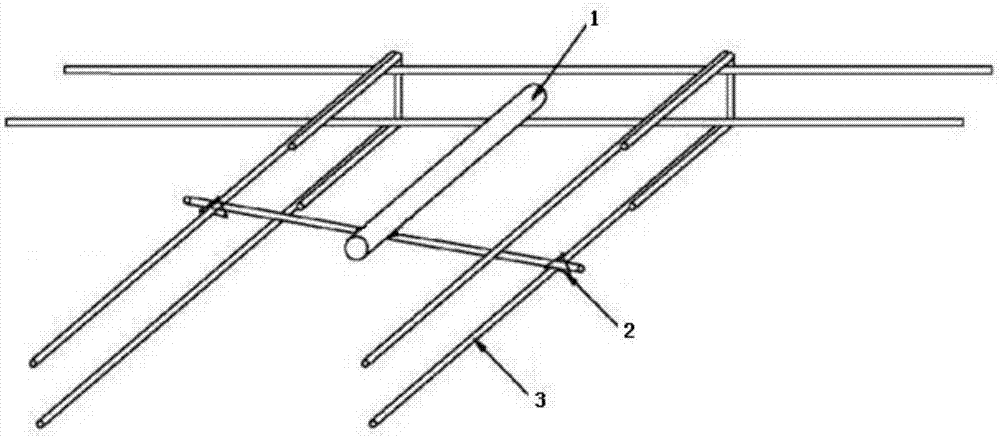

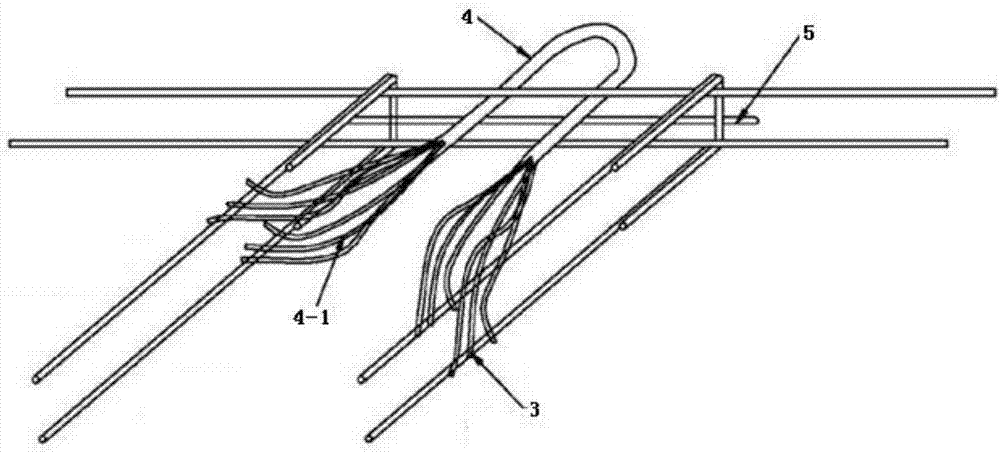

[0065] A method for making a prefabricated wall component, wherein the prefabricated wall component has a steel bar skeleton and embedded parts, and has pre-embedded steel bar holes, grouting holes and vent holes, and the manufacturing method is as follows;

[0066] 1) First, support the formwork according to the external dimensions of the wall; design the mold according to the design drawings of the concrete components, and control the precision of the mold within 2mm. , Prefabricated component structural dimensional accuracy requirements and easy vibration compaction.

[0067] When installing the formwork, it is necessary to pay attention that the formwork must be cleaned, the formwork release agent must not leak or flow, the installation and fixation of the formwork must be straight, tight, not inclined, and the size must be accurate.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com