Environment-friendly rust remover and production method thereof

A manufacturing method and rust remover technology, applied in the field of chemical preparations, can solve the problems of internal iron waste, human body danger, high risk factor, etc., achieve enhanced adhesion performance, simple, fast and efficient production method, and solve environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

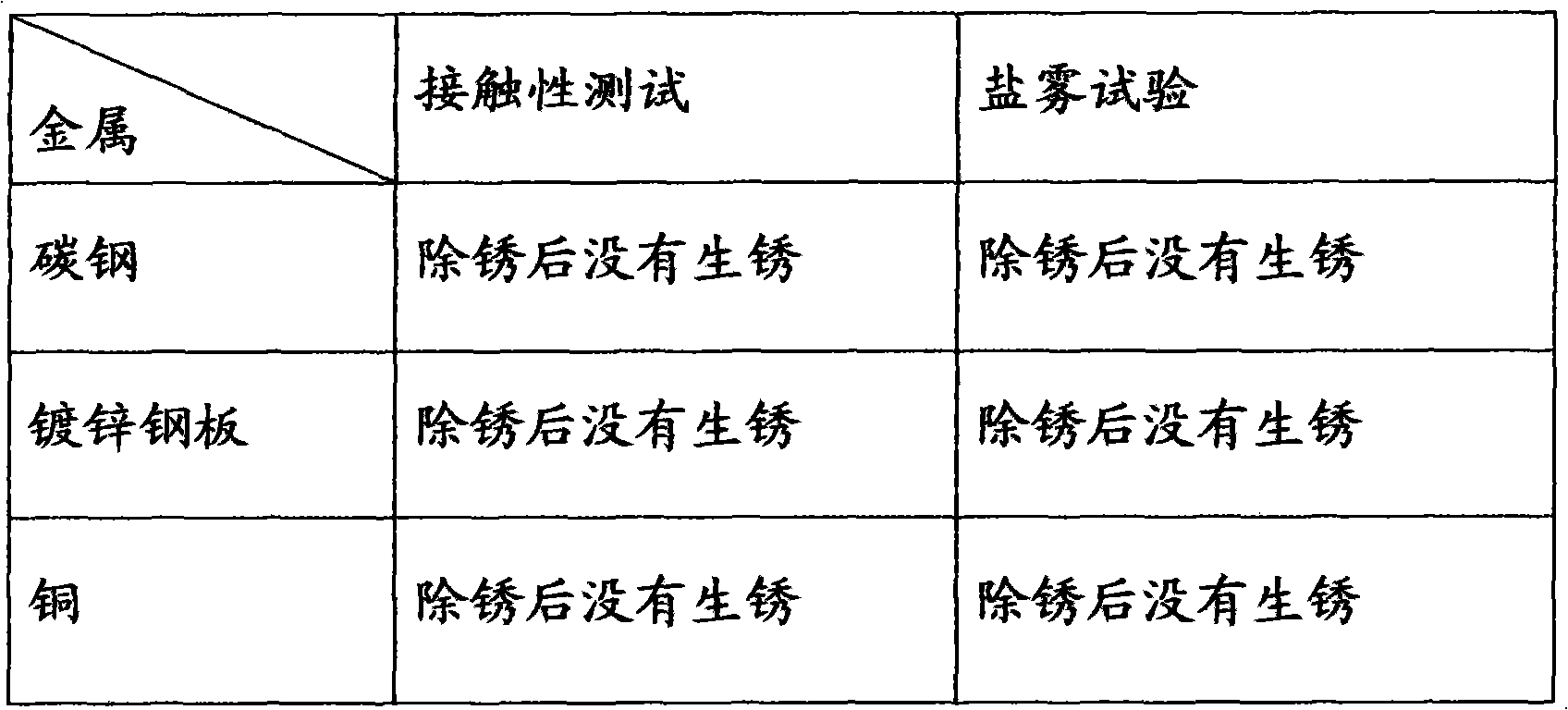

Image

Examples

Embodiment 1

[0052] First, put 18 parts of organic acid, 0.8 part of dextrin, 3 parts of sodium molybdate, 1.1 part of phosphoric acid, and 60 parts of water into the mixer and stir at a constant speed for 30 minutes at room temperature;

[0053] Then put glycerin with a mass and number ratio of 8 parts into the obtained mixed solution, stir at a constant speed at room temperature for 10 minutes, and the speed of the mixer is 25 rpm;

[0054] Next, 0.06 parts by weight of the additive SI-1 was added to the obtained mixed solution, and stirred at a constant speed at room temperature for 30 minutes, and the speed of the stirrer was 25 rpm. Then get an environmentally friendly rust remover.

[0055] In the manufacturing process of the present invention, additive SI-1 is an antacid, and its main component is sodium iodide, which is a commercially available product of Tianjin Guangxing Chemical Reagent Co., Ltd., and its main function is to convert the mixed solution product in an acidic enviro...

Embodiment 2

[0090] First put 25 parts of organic acid, 1.5 parts of dextrin, 7 parts of sodium molybdate, 1.3 parts of phosphoric acid, and 70 parts of water into the mixer and stir at a constant speed for 30 minutes at room temperature;

[0091] Then put glycerin with a mass and number ratio of 12 parts into the obtained mixed solution, stir at a constant speed at room temperature for 15 minutes, and the speed of the mixer is 25 rpm;

[0092] Next, 0.08 parts by weight of the additive SI-1 was added to the obtained mixed solution, and stirred at a constant speed at room temperature for 30 minutes, and the rotation speed of the stirrer was 25 rpm. Then get an environmentally friendly rust remover.

[0093] In the manufacturing process of the present invention, additive SI-1 is an antacid, and its main component is sodium iodide, which is a commercially available product of Tianjin Guangxing Chemical Reagent Co., Ltd., and its main function is to convert the mixed solution product in an ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com