Environmental-protection heavy-duty anticorrosive coating, and preparation method and coating method thereof

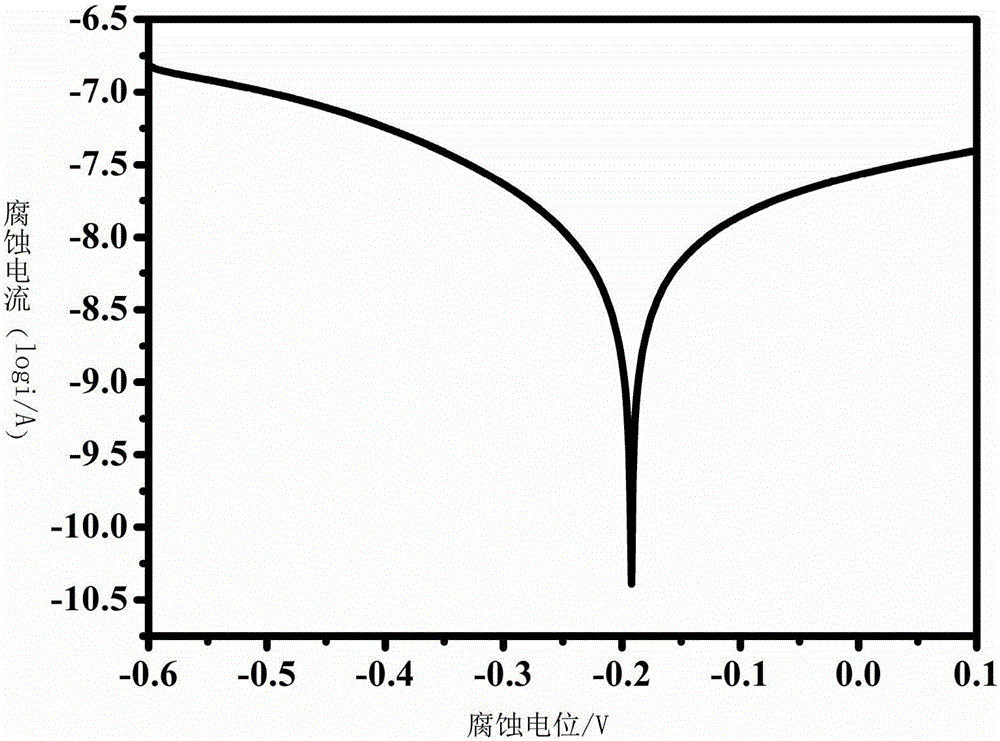

An anti-corrosion coating and heavy-duty anti-corrosion technology, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as time-consuming and labor-intensive, not in line with environmental protection, etc., to achieve improved corrosion potential, good physical properties and corrosion resistance, Anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Technical scheme of the present invention is as follows:

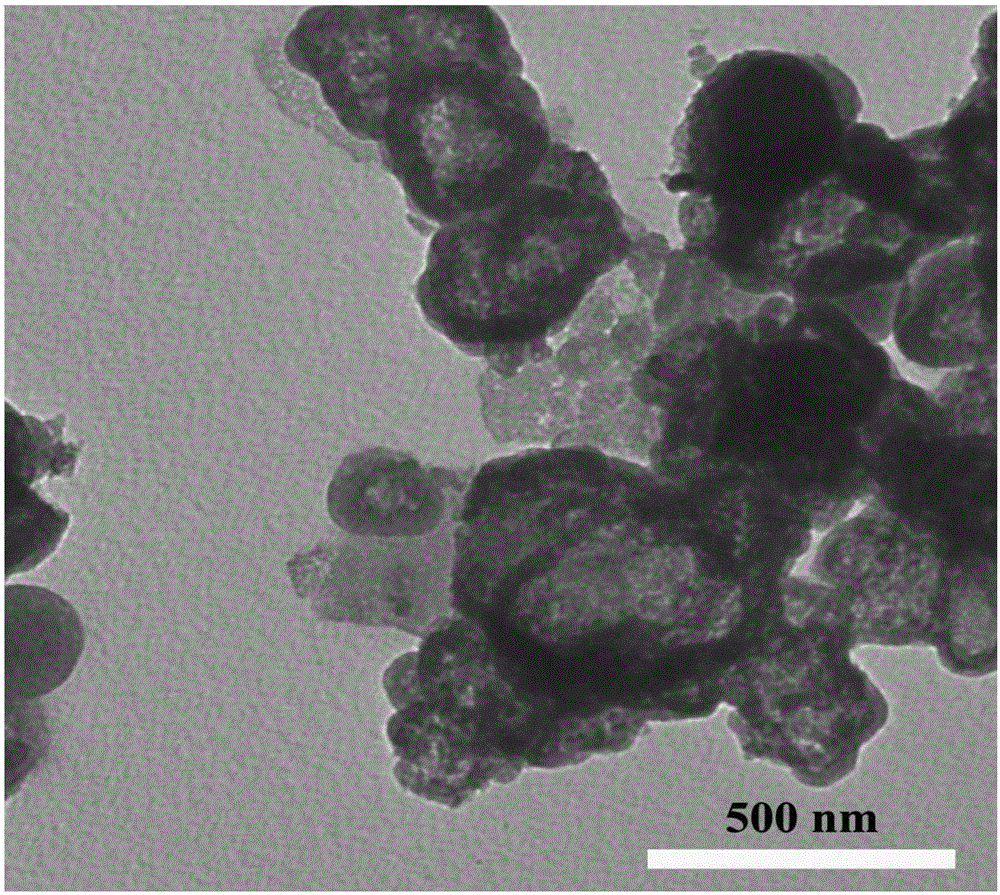

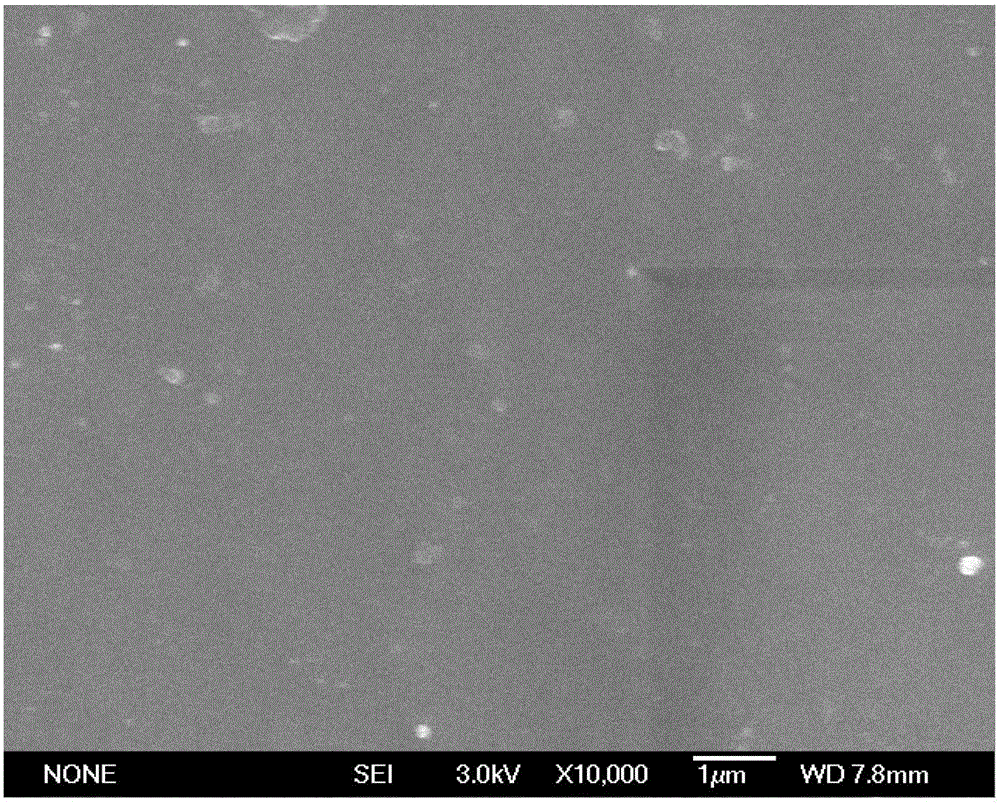

[0009] An environmentally friendly heavy-duty anti-corrosion coating, the anti-corrosion coating includes epoxy resin emulsion, silica hollow microspheres, silane coupling agent, anti-flash rust agent, anti-settling agent and curing agent, wherein, epoxy resin emulsion: silica Hollow ball: silane coupling agent: anti-flash rust agent: anti-settling agent: curing agent The mass ratio is 100:(1-10):(0.5-2):(0.1-1):(1-5):( 10-20);

[0010] The silane coupling agent is one or both of silane coupling agent KH550, silane coupling agent KH560, silane coupling agent KH570, silane coupling agent KH580, silane coupling agent KH602, silane coupling agent KH792 Mix the above;

[0011] Described anti-flash rust agent is anti-flash rust agent CHO7A;

[0012] The anti-settling agent is anti-settling agent 163A;

[0013] The curing agent is a water-soluble modified fatty amine.

[0014] Preferably in the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com