Environment-friendly steel rust remover and preparation method thereof

A rust remover and steel technology, applied in the field of steel rust remover, can solve the problems of long rust removal time, pollute the environment, easy to return rust, etc., and achieve the effect of small investment, uniform texture and moderate dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment one: in this embodiment, the environment-friendly iron and steel derusting agent is made of 20% citric acid, 5% oxalic acid, 30% phosphoric acid, 1.0% sodium alkylbenzene sulfonate, 2% emulsifier NP-10, 4.5% by weight percentage % urea and the remainder of deionized water; its preparation method is completed according to the operation: first add 1 / 2 of water in the reaction kettle, and then add phosphoric acid, citric acid, oxalic acid, Sodium alkylbenzene sulfonate, corrosion inhibitor and emulsifier, then add the remaining amount of water, stir at a constant speed until completely dissolved.

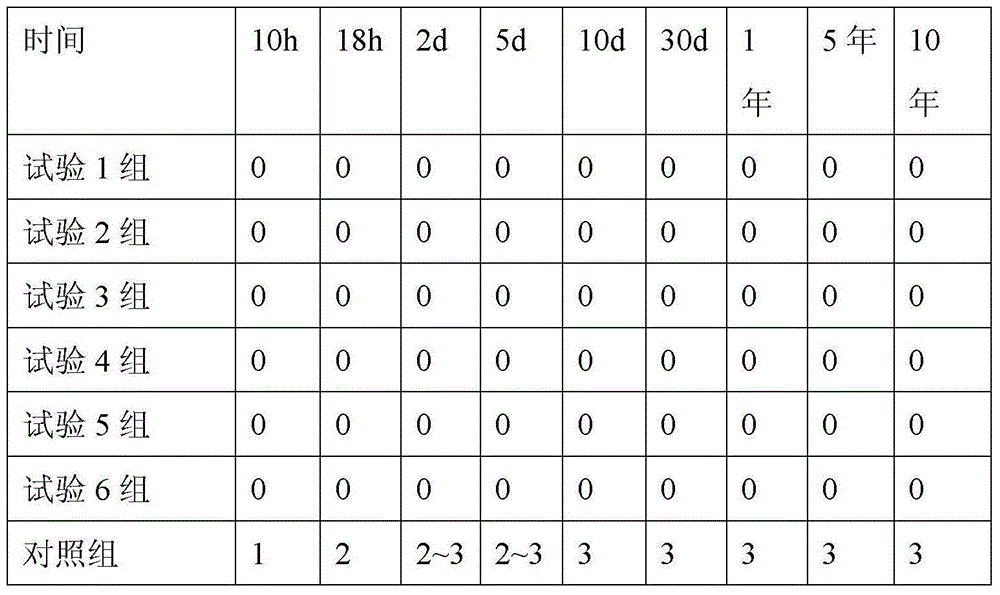

[0022] The properties of the environment-friendly iron and steel derusting agent in this embodiment are as follows

[0023] Table 1

[0024] Exterior

specific Embodiment approach 2

[0025] Specific embodiment two: in this embodiment, the environment-friendly iron and steel derusting agent is made of 17% citric acid, 1% oxalic acid, 40% phosphoric acid, 1.5% sodium alkylbenzene sulfonate, 1% emulsifier AEO-9, 5.0% by weight percentage % EDTA and the remainder deionized water.

[0026] The preparation method of this embodiment is the same as that of Embodiment 1.

[0027] The properties of the environment-friendly iron and steel derusting agent in this embodiment are as follows

[0028] Table 2

[0029] Exterior

specific Embodiment approach 3

[0030] Specific embodiment three: in this embodiment, the environment-friendly iron and steel derusting agent is made of 25% citric acid, 8% oxalic acid, 20% phosphoric acid, 0.8% sodium alkylbenzene sulfonate, 3% emulsifier AEO-9, 1.0% by weight percentage % hexamethylenetetramine and the remainder deionized water.

[0031] The preparation method of this embodiment is the same as that of Embodiment 1.

[0032] The properties of the environment-friendly iron and steel derusting agent in this embodiment are as follows

[0033] table 3

[0034] Exterior

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com