Rust removal preparation device for LED (light-emitting diode) lamp holder manufacture

A technology of LED lamp holders and equipment, which is applied in the direction of mixer accessories, dissolving machines, mixers, etc., can solve the problems of inability to collect rust removers, inability to prepare multi-stage stirring, etc., and achieve the effect of full mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

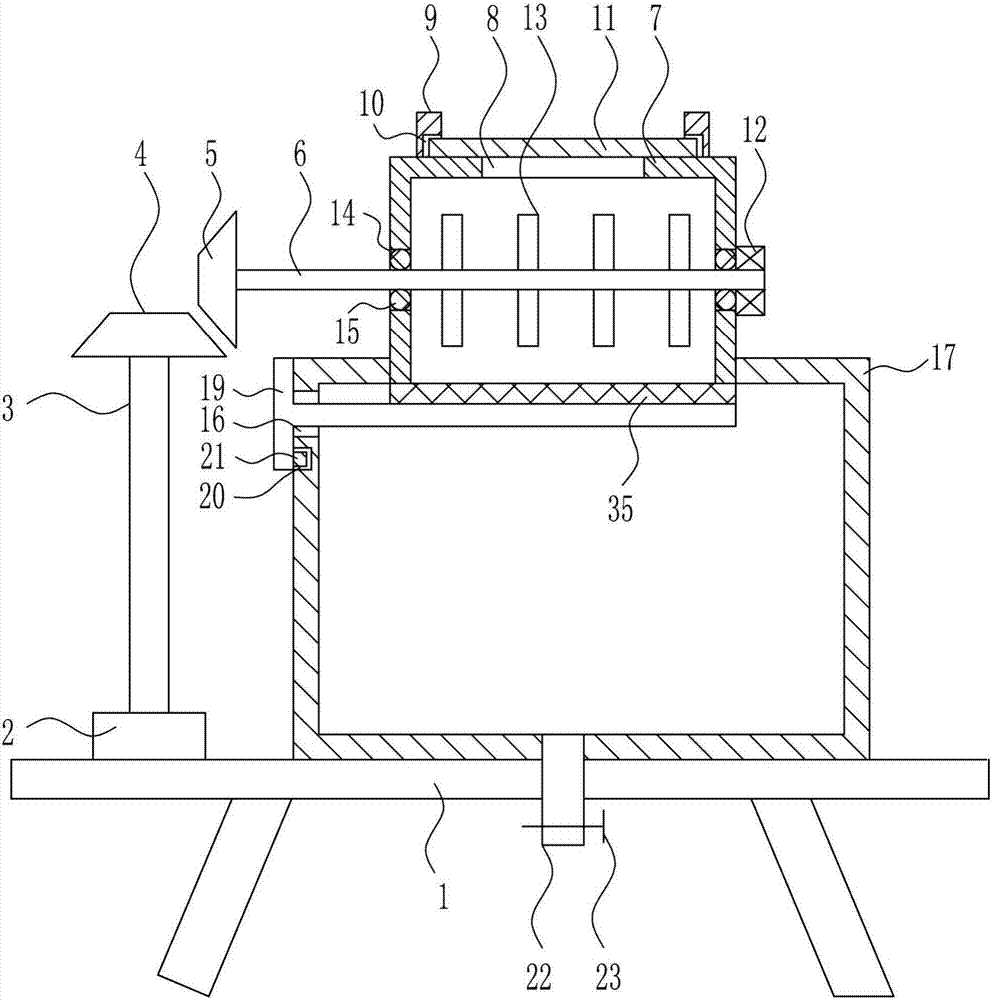

Embodiment 1

[0029] A kind of derusting preparation equipment for LED lamp holder production, such as Figure 1-4As shown, it includes a workbench 1, a motor 2, a first rotating rod 3, a first bevel gear 4, a second bevel gear 5, a second rotating rod 6, a mixing box 7, a pole 9, a baffle plate 11, a first Bearing seat 12, first stirring rod 13, sealing ring 15, storage box 17, pull rod 19, rubber block 21, discharge pipe 22, valve 23 and filter screen 35, motor 2 and motor 2 are installed on the left side of the top of workbench 1 The first rotary rod 3 is connected to the output shaft of the first rotary rod 3, the first bevel gear 4 is connected to the top of the first rotary rod 3, the storage box 17 is connected to the right side of the top of the workbench 1, and the bottom center of the storage box 17 is connected to the discharge pipe 22. The discharge pipe 22 is provided with a valve 23, and the upper part of the left wall of the storage box 17 has a second small hole 16, and the ...

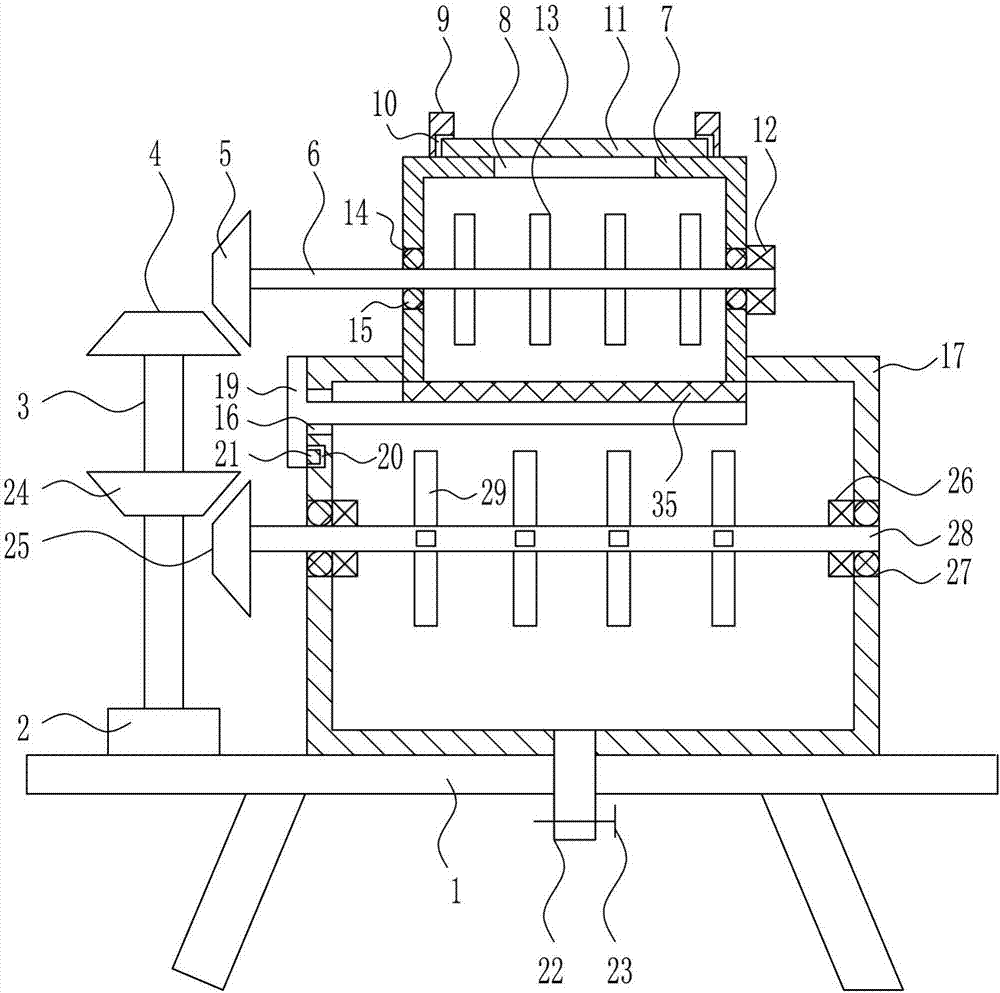

Embodiment 2

[0031] A kind of derusting preparation equipment for LED lamp holder production, such as Figure 1-4 As shown, it includes a workbench 1, a motor 2, a first rotating rod 3, a first bevel gear 4, a second bevel gear 5, a second rotating rod 6, a mixing box 7, a pole 9, a baffle plate 11, a first Bearing seat 12, first stirring rod 13, sealing ring 15, storage box 17, pull rod 19, rubber block 21, discharge pipe 22, valve 23 and filter screen 35, motor 2 and motor 2 are installed on the left side of the top of workbench 1 The first rotary rod 3 is connected to the output shaft of the first rotary rod 3, the first bevel gear 4 is connected to the top of the first rotary rod 3, the storage box 17 is connected to the right side of the top of the workbench 1, and the bottom center of the storage box 17 is connected to the discharge pipe 22. The discharge pipe 22 is provided with a valve 23, and the upper part of the left wall of the storage box 17 has a second small hole 16, and the...

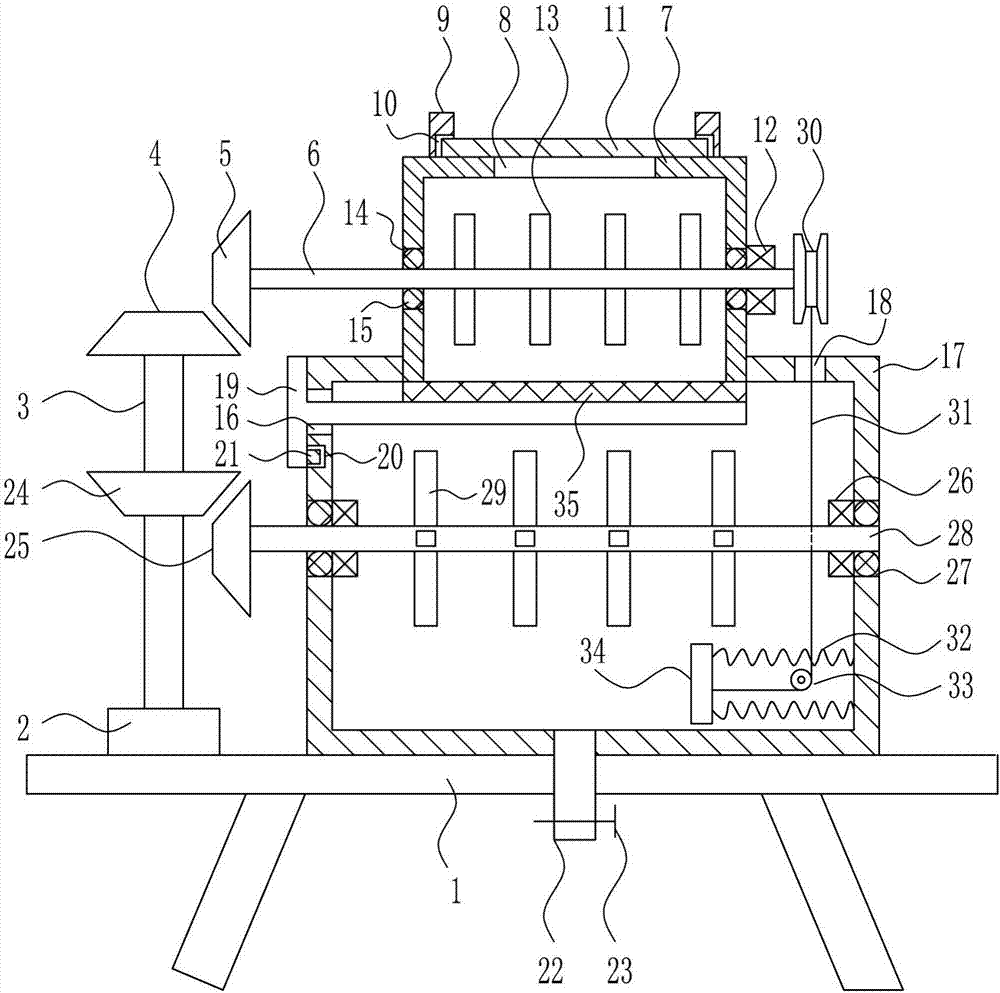

Embodiment 3

[0034] A kind of derusting preparation equipment for LED lamp holder production, such as Figure 1-4 As shown, it includes a workbench 1, a motor 2, a first rotating rod 3, a first bevel gear 4, a second bevel gear 5, a second rotating rod 6, a mixing box 7, a pole 9, a baffle plate 11, a first Bearing seat 12, first stirring rod 13, sealing ring 15, storage box 17, pull rod 19, rubber block 21, discharge pipe 22, valve 23 and filter screen 35, motor 2 and motor 2 are installed on the left side of the top of workbench 1 The first rotary rod 3 is connected to the output shaft of the first rotary rod 3, the first bevel gear 4 is connected to the top of the first rotary rod 3, the storage box 17 is connected to the right side of the top of the workbench 1, and the bottom center of the storage box 17 is connected to the discharge pipe 22. The discharge pipe 22 is provided with a valve 23, and the upper part of the left wall of the storage box 17 has a second small hole 16, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com