Device for cleaning petroleum drilling rod

A technology for oil drill pipes and equipment, which is applied in the field of equipment for cleaning oil drill pipes. It can solve the problems of low manual cleaning efficiency, high operating intensity, and physical hazards for construction workers, achieving high efficiency, reducing work cycles, and increasing Effect of spray range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

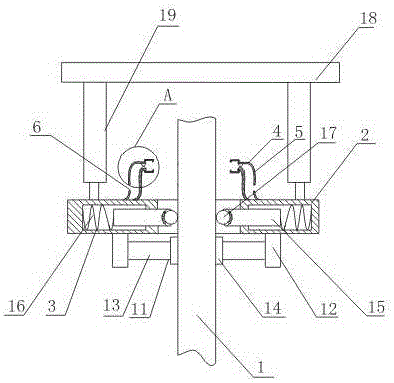

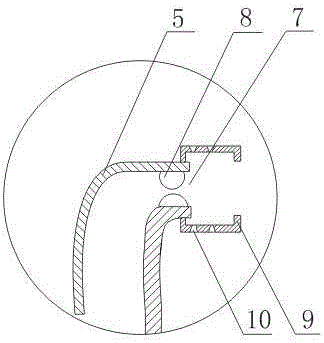

[0020] Such as figure 1 , figure 2 As shown, the equipment for cleaning the oil drill pipe includes an annular rotating plate 2 sleeved on the outer diameter of the oil drilling pipe 1, and the inner wall of the annular rotating plate 2 has a ring cavity; The clamping device 3 in the ring cavity; also includes a spray washing device 4 fixed on the upper surface of the annular rotating plate 2, the spray washing device 4 includes a nozzle body 5 with a cavity structure, and an inlet is opened on one side of the nozzle body 5. There is a water outlet A7 on the other side of the water outlet 6; it also includes a hemisphere 8 evenly arranged on the inner wall of the nozzle body 5 around the water outlet A7, and the hemisphere 8 is made of rubber material; The cover body 9 which is a cavity structure, the water outlet A7 is located in the cavity structure of the cover body 9;

[0021] In this embodiment, the pipeline for transporting the derusting agent is connected to the wate...

Embodiment 2

[0023] On the basis of Embodiment 1, this embodiment also includes a cleaning device 11 arranged on the lower surface of the annular rotating plate 2. The cleaning device 11 includes a connecting block 12, a connecting rod 13 connected with the connecting block 12, and a connecting rod 13 fixed on the connecting rod 13. The grinding body 14 at the end and the side of the connection block 12 are arranged on the annular rotating plate 2 .

[0024] The grinding body 14 in this embodiment can derust the oil drilling pipe 1 when the annular rotating plate 2 moves or rotates up and down along the axis of the oil drilling pipe 1, and the grinding sheet made of quartz stone has a better effect.

Embodiment 3

[0026] In this embodiment, on the basis of Embodiment 1 or Embodiment 2, the clamping device 3 includes a support rod 15 slidably arranged in the ring cavity, and also includes two ends connected to the inner wall of the ring cavity and the rear end of the support rod 15 respectively. The spring 16, the front end of the support rod 15 passes through the opening of the ring cavity and is arranged outside the ring cavity, and a universal ball 17 arranged at the front end of the support rod 15 is also included.

[0027] In this embodiment, when the annular rotating plate 2 is not sleeved on the oil drilling pipe 1, the spring 16 will be in the original state, and when the annular rotating plate 2 is sleeved on the oil drilling pipe 1, the spring 16 will be compressed to support The universal ball 17 at the front end of the rod 15 will squeeze the oil drill pipe 1 . The arrangement of the spring 16 and the universal ball 17 makes the present invention applicable to oil drill pipes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com