Formula and technique for neutral rust remover for rust cleaning of sheet material

A rust remover and board technology, applied in the process of using neutral rust remover to remove rust on board, neutral rust remover formula field, can solve the problems of polluting the environment, endangering human health, time-consuming and labor-intensive, etc. Achieve the effect of simple operation, low cost, human body and environment friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

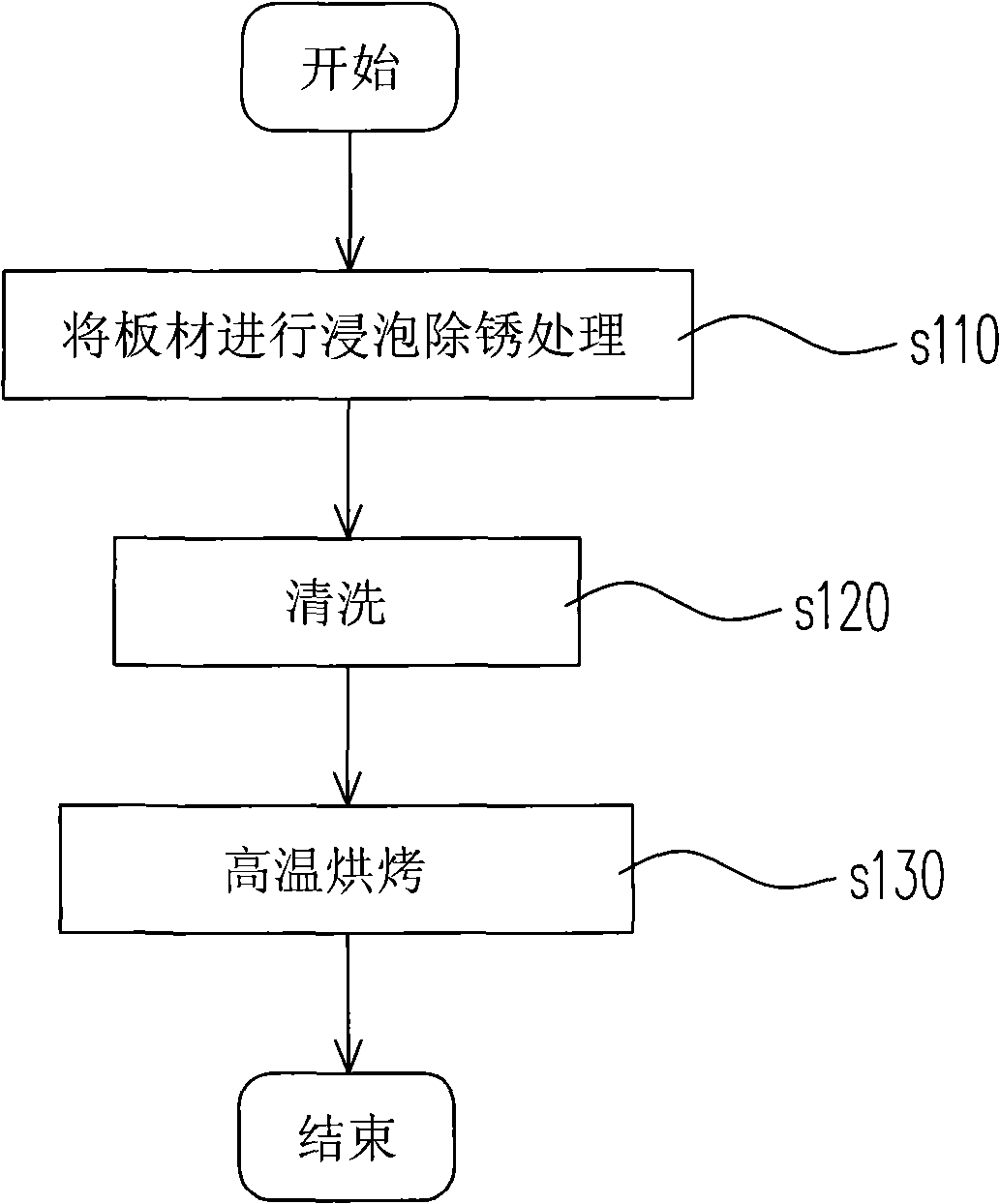

Method used

Image

Examples

Embodiment

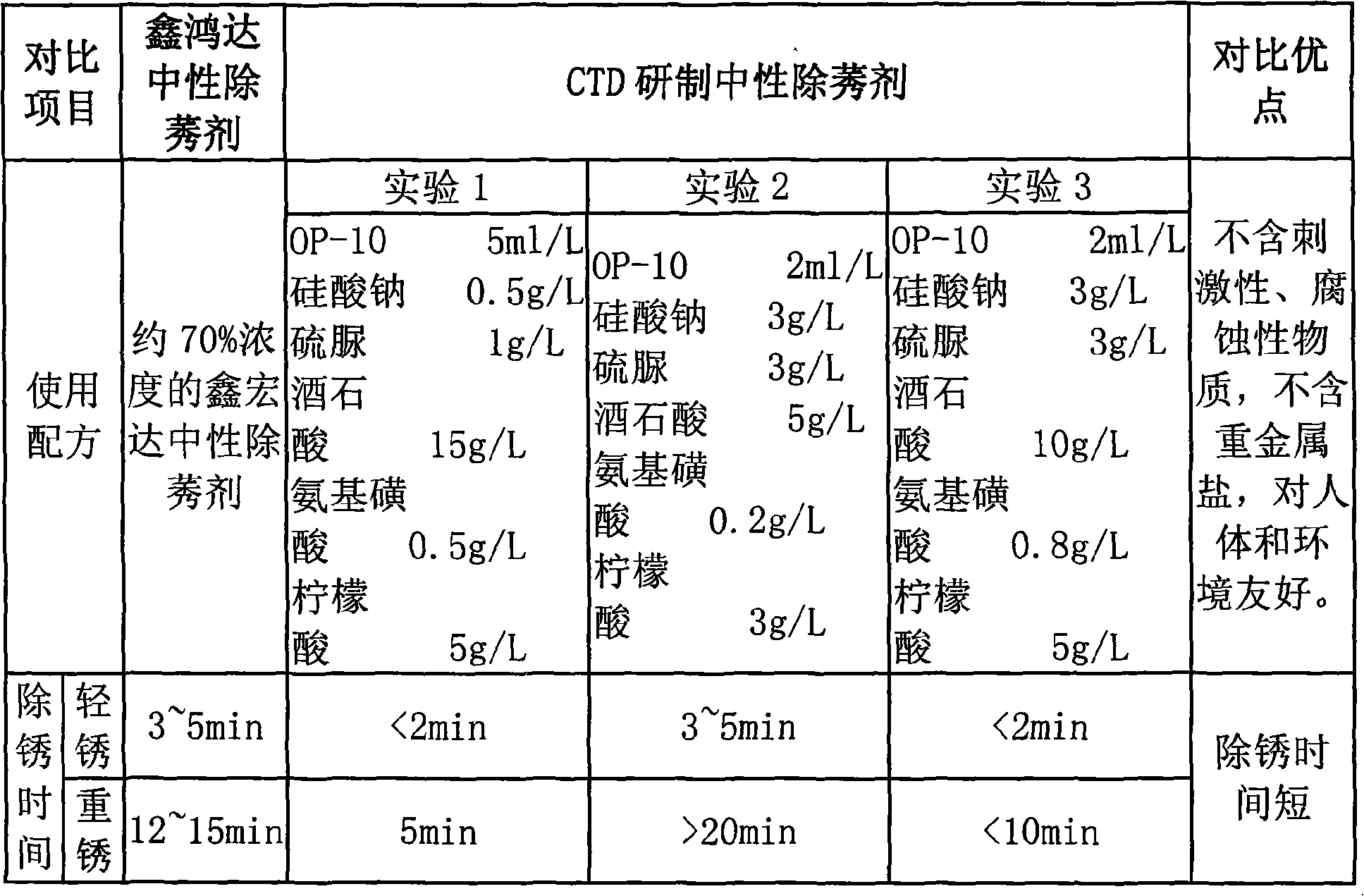

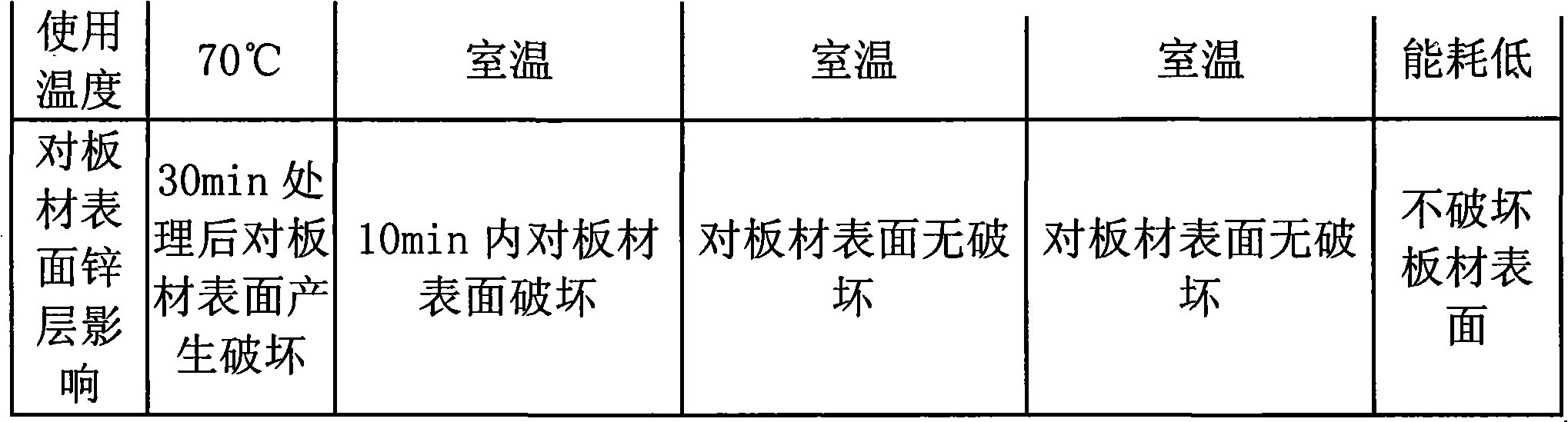

[0044] According to the above steps, the boards treated with the neutral rust remover solution disclosed in the present invention and the boards treated with the purchased neutral rust remover--Xinhongda were subjected to performance tests. The test comparison results are shown in Table 1. Show.

[0045] Table 1: Comparison of performance test results of plates treated with the neutral rust remover solution of the present invention and those treated with Xinhongda

[0046]

[0047]

[0048] In summary, compared with the prior art, the present invention produces the following technical effects:

[0049] The formula of the neutral rust remover disclosed by the invention can effectively derust the plate, the cost of the neutral rust remover is low, it can be used at normal temperature, it is not easy to generate acid mist, and it is friendly to the human body and the environment; and No damage to the zinc layer on the surface of the plate, and the operation is simple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com