Neutral rust removal and prevention agent, preparation method and implementation process

A rust remover and neutral technology, applied in the field of neutral rust remover and antirust agent and its preparation, can solve the problems of damage to the overall solidity of metal, the speed of rust removal cannot meet the requirements, and the temperature of rust removal treatment is high, so as to achieve strong industrial Practicality and economy, low cost, and the effect of accelerating the stripping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

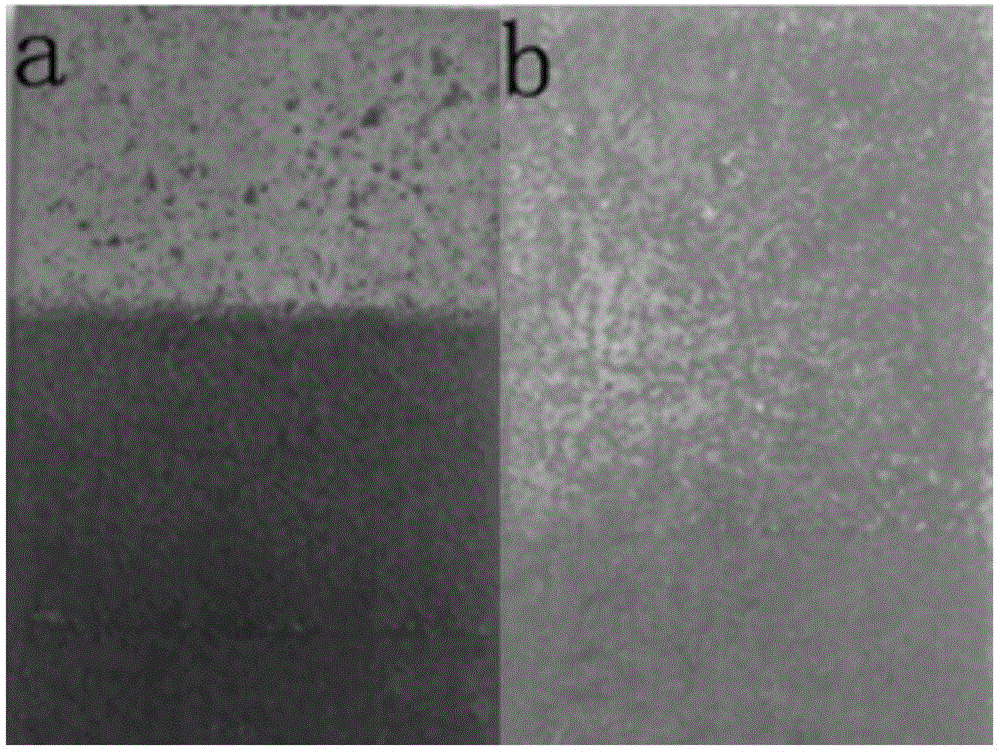

Image

Examples

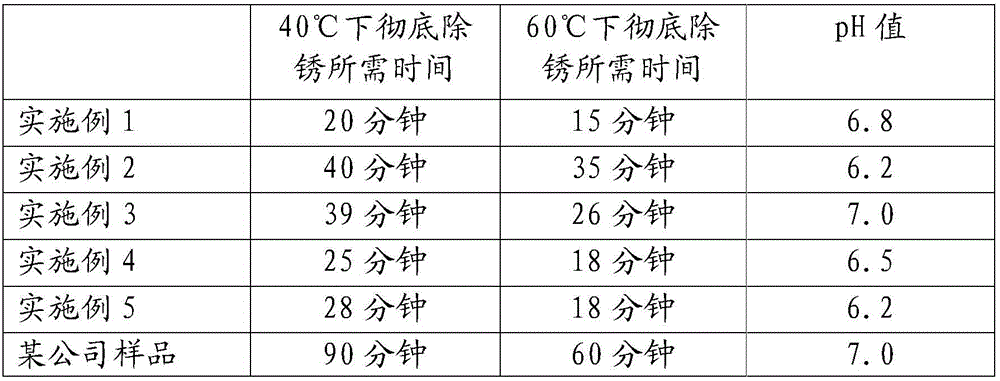

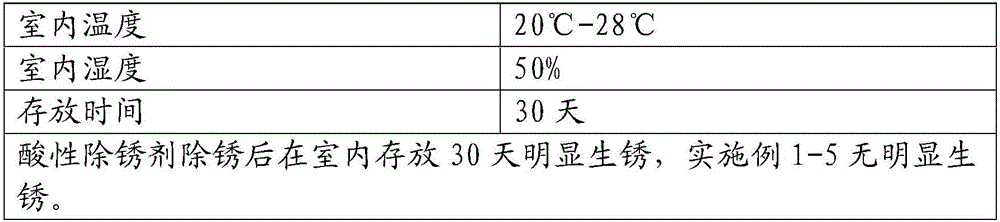

Embodiment 1

[0033] Take 40.1kg of water, 0.9kg of complexing agent, 0.6kg of chelating agent, and 0.3kg of dispersing agent into the reactor with stirring, and stir thoroughly to obtain liquid A; take another reactor, add 40.1kg of water, dihydroxyethylidene Mix 10kg of phosphonic acid and 3kg of sodium hydroxide to obtain liquid B; slowly pour liquid B into liquid A, then add 5 kg of sodium silicate aqueous solution with a mass fraction of 60% into the mixed liquid and stir well.

[0034] The above-mentioned complexing agent is selected from the compound of disodium edetate, sodium citrate and sodium hexametaphosphate, and the mass fraction of the three components in the neutral rust remover and antirust agent is 0.3kg.

[0035] The above-mentioned chelating agent is selected from the compound of sodium gluconate, sodium alginate and triethanolamine, wherein sodium gluconate accounts for 0.4 kg in total mass percentage, and sodium alginate and triethanolamine account for 0.1 kg in total m...

Embodiment 2

[0038] Take 26.3kg of water, 10kg of complexing agent, 0.9kg of chelating agent, and 0.5kg of dispersant into the reactor with stirring, and stir thoroughly to obtain liquid A; take another reactor, add 26.3kg of water, hydroxyethylidene diphosphine Mix 20 kg of acid and 6 kg of sodium hydroxide to obtain liquid B; slowly pour liquid B into liquid A, then add 10 kg of sodium silicate aqueous solution with a mass fraction of 40% into the mixed liquid and stir well.

[0039] The above-mentioned complexing agent is selected from the compound of disodium edetate, sodium citrate and sodium hexametaphosphate, and the mass fraction of the three components in the neutral rust remover and antirust agent is 0.33kg.

[0040] The above-mentioned chelating agent is selected from the compound of sodium gluconate, sodium alginate and triethanolamine, wherein sodium gluconate accounts for 0.4 kg in total mass percentage, and sodium alginate and triethanolamine account for 0.2 kg in total mass ...

Embodiment 3

[0043] According to the calculation of the total mass fraction, take 38.9kg of water, 1.0kg of complexing agent, 0.8kg of chelating agent, and 0.4kg of dispersant into the reactor with stirring, and stir thoroughly to obtain liquid A; take another reactor and add 38.9kg of water kg, 15 kg of hydroxyethylidene diphosphonic acid, 5 kg of sodium hydroxide, and fully stir to obtain liquid B; slowly pour liquid B into liquid A, and then add 8 kg of sodium silicate aqueous solution with a mass fraction of 40% to the mixed liquid Stir well.

[0044] The above-mentioned complexing agent is selected from the compound of disodium edetate and sodium citrate, and the mass of the two components in the neutral rust remover and antirust agent is 0.5kg.

[0045] The above-mentioned chelating agent is selected from the compound of sodium gluconate and sodium alginate, wherein the quality of sodium gluconate is 0.6kg, and the quality of sodium alginate is 0.2kg. What the above-mentioned disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com