Fertilizer synergist and preparation method thereof

A fertilizer synergist and formula technology, applied in fertilizer mixture, fertilization device, application, etc., can solve the problems of no environmental protection and soil improvement, poor slow-release synergistic effect, complicated production process, etc., to improve crop quality and yield, reduce topdressing and links, and shorten the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

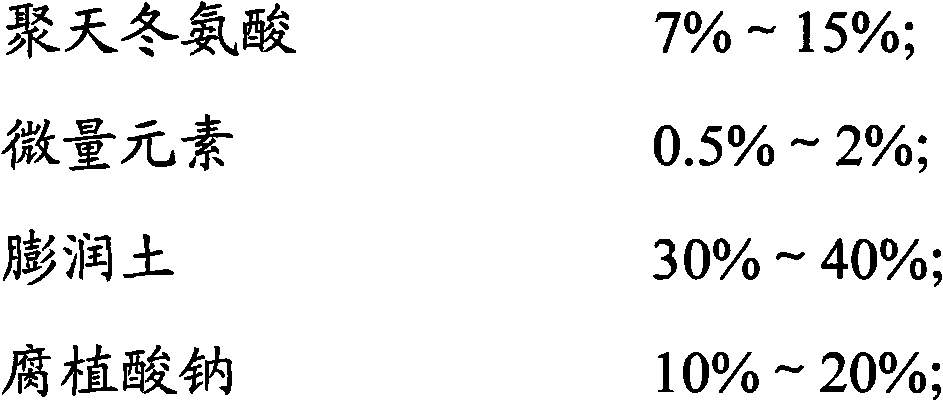

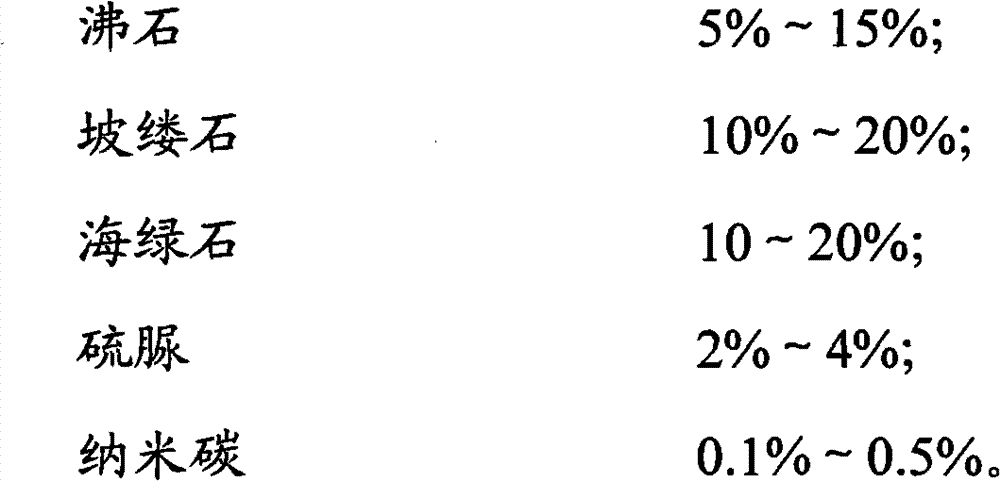

Image

Examples

preparation example Construction

[0027] The embodiment of the present invention also provides a kind of preparation method, it comprises the following steps:

[0028] S01: Weigh each component according to the formula of the above-mentioned fertilizer synergist;

[0029] S02: mixing the polyaspartic acid, trace elements, bentonite and nano carbon to obtain a mixture I;

[0030] S03: Mix the zeolite and palygorskite and raise the temperature to 100°C-200°C, add sodium humate, adjust the pH value to 3-6, and perform irradiation treatment to obtain mixture II;

[0031] S04: Mix the mixture I, mixture II, activated glauconite and thiourea to obtain the fertilizer synergist.

[0032] Specifically, in step S01, all materials are weighed accurately, accurate to 0.001 kilogram. The preferred contents and types of each component in the fertilizer synergist formulation are as above, and will not be repeated here to save space.

[0033] In the above step S02, the polyaspartic acid, trace elements, bentonite and nano-...

Embodiment 1

[0039] Components and weight percentages thereof of the fertilizer synergist of the present embodiment are:

[0040]

[0041] Weigh each component according to the formula of the above-mentioned fertilizer synergist; mix the polyaspartic acid, trace elements, bentonite and nano-carbon evenly to obtain a mixture I; pulverize the zeolite and palygorskite into 100 meshes, Then mix and heat up to 150°C, add sodium humate, adjust the pH value to 4, and perform irradiation treatment to obtain mixture II; mix the mixture I, mixture II, activated glauconite and thiourea to obtain the fertilizer synergist. Wherein, the radiation source of irradiation treatment is preferably Co60, and the total dose of radiation source is 2×10 2 GY / S, radiation time is 10×10 2 Second. The irradiation distance of the radiation source is 3 meters. The fertilizer synergist is obtained by mixing the mixture I, the mixture II, activated glauconite and thiourea.

Embodiment 2

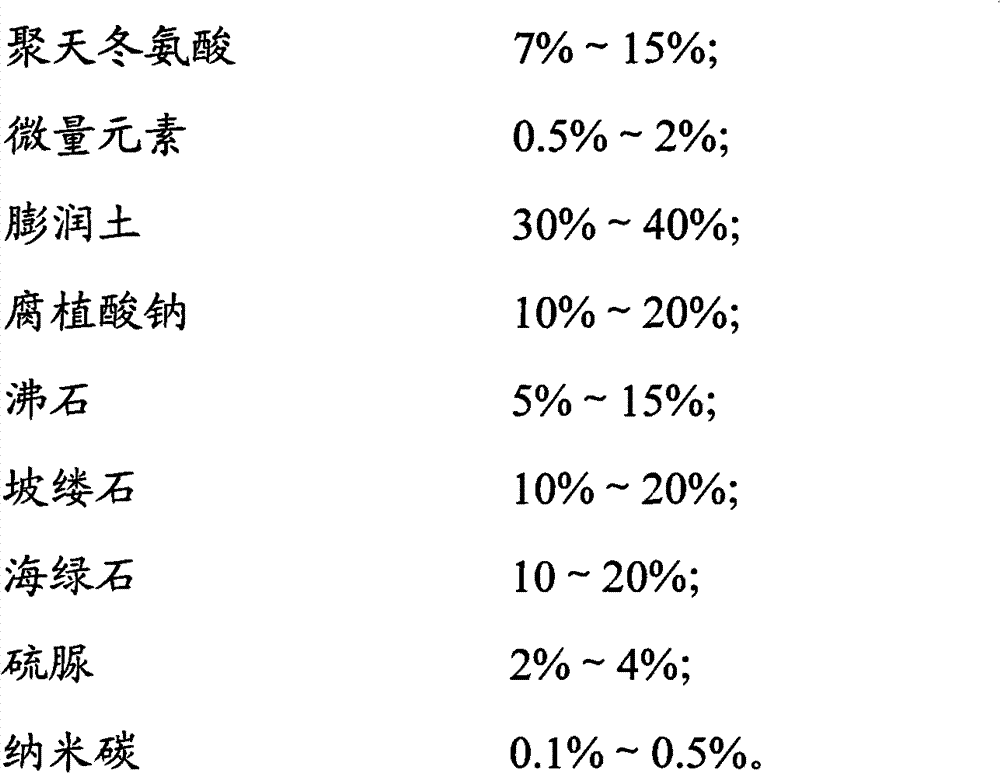

[0043] Components and weight percentages thereof of the fertilizer synergist of the present embodiment are:

[0044]

[0045] Weigh each component according to the formula of the above-mentioned fertilizer synergist; mix the polyaspartic acid, trace elements, bentonite and nano-carbon evenly to obtain a mixture I; pulverize the zeolite and palygorskite into 100 meshes, Then, the temperature was raised to 100°C, sodium humate was added, the pH value was adjusted to 3, and the mixture II was obtained by irradiation treatment; the mixture I, mixture II, activated glauconite and thiourea were mixed to obtain the fertilizer booster potency. Wherein, the radiation source of irradiation treatment is preferably Co60, and the total dose of radiation source is 0.1×10 2 GY / S, radiation time is 20×10 2 Second. The irradiation distance of the radiation source is 1 meter. The fertilizer synergist is obtained by mixing the mixture I, the mixture II, activated glauconite and thiourea. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com