Polyaspartic acid ester polyurea protective paint with good corrosion resistance, preparation method, using method and application

An aspartate, protective coating technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problem of high temperature resistance and corrosion resistance not as good as fluorocarbon coatings, poor interlayer adhesion, hindering application and other issues, to achieve good mechanical properties and corrosion resistance, strong adhesion, and reduce maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

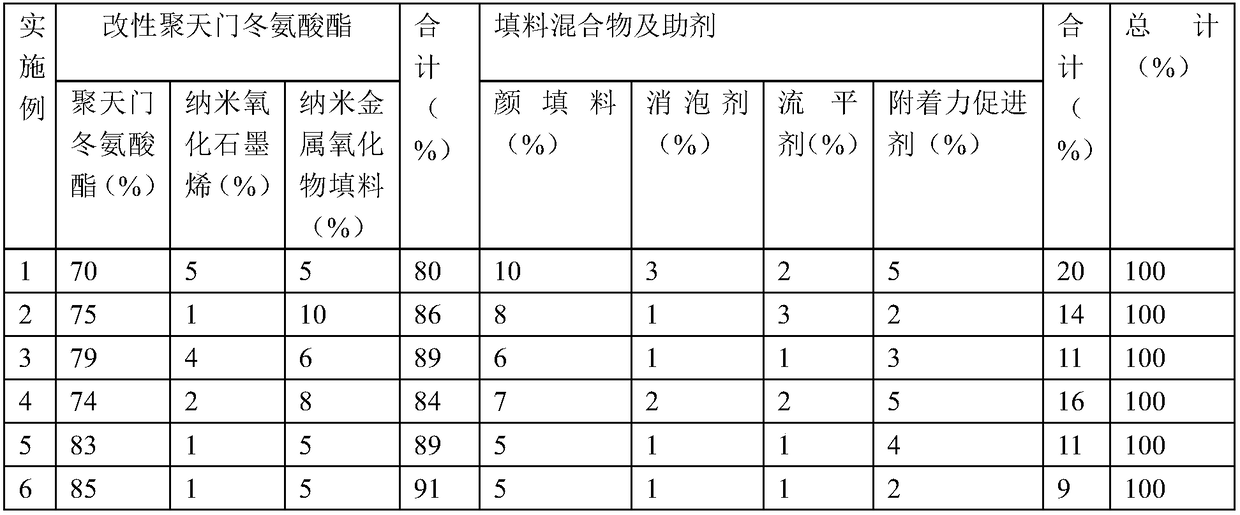

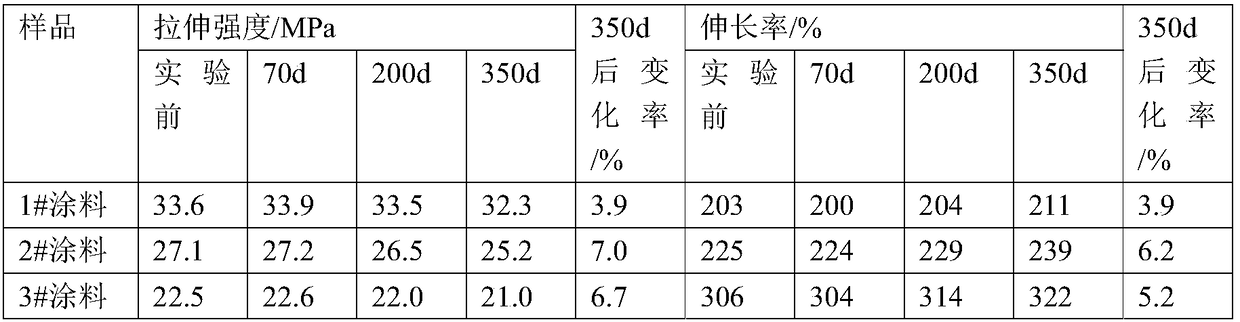

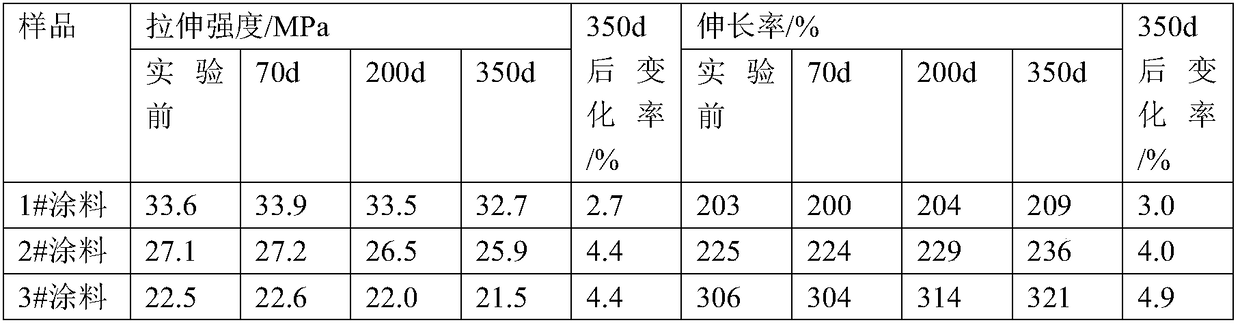

Examples

Embodiment 1

[0030] The purpose of this embodiment is to provide a polyaspartic acid ester polyurea protective coating with good corrosion resistance and a preparation method thereof, specifically comprising the following steps:

[0031] (1) Preparation of material A:

[0032] In percent by weight, weigh 20% of polytetrahydrofuran diol and 80% of diphenylmethane-4,4-diisocyanate into a three-necked flask equipped with a stirrer, a heating device and a condenser, and heat up to 70-80 After mixing at ℃ for 12 hours, the number of moles of NCO synthesized is 10% of the total number of moles of the reaction substrates;

[0033] (2) Preparation of component B:

[0034] Weigh the corresponding amount of amino-terminated polyether D230, add it into a three-necked bottle equipped with a stirrer, a heating device and a condenser, raise the temperature to 70-90°C, add the corresponding amount of diethyl maleate dropwise, and the dropping time After 30 minutes, the corresponding amount of nano-grap...

Embodiment 2

[0038] The purpose of this embodiment is to provide a polyaspartic acid ester polyurea protective coating with good corrosion resistance and a preparation method thereof, specifically comprising the following steps:

[0039] (1) Preparation of material A:

[0040] In terms of weight percentage, weigh 25% of polytetrahydrofuran triol and 75% of isophorone diisocyanate into a three-necked flask equipped with a stirrer, a heating device and a condenser, heat up to 70-80°C and mix to react 12h, the number of moles of synthesized NCO is 10% of the prepolymer of the total number of moles of the reaction substrate;

[0041] (2) Preparation of component B:

[0042] Weigh the corresponding amount of amino-terminated polyether D400, add it into a three-necked bottle equipped with a stirrer, a heating device and a condenser, raise the temperature to 70-90°C, add the corresponding amount of dimethyl maleate dropwise, and the dropping time After 30 minutes, the corresponding amount of nano...

Embodiment 3

[0046] The purpose of this embodiment is to provide a polyaspartic acid ester polyurea protective coating with good corrosion resistance and a preparation method thereof, specifically comprising the following steps:

[0047] (1) Preparation of material A:

[0048] In terms of weight percentage, weigh 30% of polyethylene glycol diol and 70% of hexamethylene diisocyanate into a three-necked flask equipped with a stirrer, a heating device and a condenser, and heat up to 70-80°C for mixing After reacting for 12 hours, the number of moles of synthetic NCO is 15% of the prepolymer of the total number of moles of the reaction substrate;

[0049] (2) Preparation of component B:

[0050] Weigh the corresponding amount of amino-terminated polyether T403, add it into a three-necked bottle equipped with a stirrer, a heating device and a condenser, raise the temperature to 70-90°C, add the corresponding amount of dibutyl maleate dropwise, and the dropping time After 30 minutes, the corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com