Water-soluble mineral fertilizer and preparation method thereof

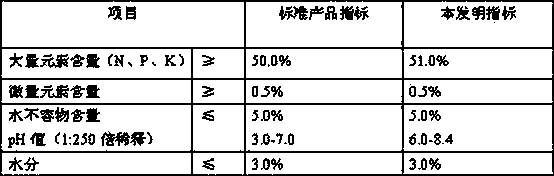

A water-soluble, mineral fertilizer technology, applied in fertilization devices, fertilizer mixtures, agricultural gas emission reduction, etc., can solve the problems of unsuitable water and fertilizer integration, limit the wide application of water-soluble fertilizers, and cannot be irrigated with water, etc., to achieve suitable Large-scale production, short production process and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

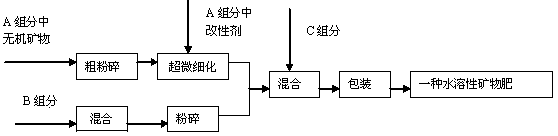

Method used

Image

Examples

Embodiment example 1

[0046] Implementation case 1. A kind of water-soluble mineral fertilizer, its composition ratio is as follows, all are parts by weight:

[0047] The raw material composition and ratio of A component are:

[0048] 20 parts of potassium feldspar, 30 parts of phosphate rock, 10 parts of medical stone, 5 parts of diatomaceous earth, 5 parts of bentonite, 2 parts of hydroxyethyl cellulose,

[0049] The raw material composition and ratio of component B are:

[0050] 10 parts of urea, 10 parts of ammonium dihydrogen phosphate, 1 part of carboxymethyl starch, 1 part of biological nitrogen-fixing bacteria, 0.1 part of N-butylthiophosphoric diamide (BTPT), 0.1 part of dicyandiamide,

[0051] The raw material composition and ratio of component C are: 0.8 parts of polyaspartic acid, 2 parts of polyvinylpyrrolidone, and 2 parts of casein.

[0052] The preparation method is as follows:

[0053] (1) Preparation of component A: Grind 20 parts of potassium feldspar, 30 parts of phosphate ...

Embodiment example 2

[0058] Implementation case 2. As described in Example 1, its difference is that each raw material component is as follows, all in parts by weight:

[0059] The raw material composition and ratio of A component are:

[0060] 15 parts of potassium feldspar, 30 parts of phosphate rock, 10 parts of medical stone, 5 parts of diatomaceous earth, 5 parts of bentonite, 3 parts of hydroxyethyl cellulose,

[0061] The raw material composition and ratio of component B are:

[0062] 10 parts of urea, 14 parts of ammonium dihydrogen phosphate, 1 part of carboxymethyl starch, 1 part of biological nitrogen-fixing bacteria, 0.1 part of N-butylthiophosphoric acid diamide (BTPT), 0.1 part of dicyandiamide,

[0063] The raw material composition and ratio of component C are: 0.8 parts of polyaspartic acid, 2 parts of polyvinylpyrrolidone, and 2 parts of casein.

[0064]

Embodiment example 3

[0065] Implementation case 3. As described in Example 1, its difference is that each raw material component is as follows, all in parts by weight:

[0066] The raw material composition and ratio of A component are:

[0067] 15 parts of potassium feldspar, 30 parts of phosphate rock, 10 parts of medical stone, 5 parts of diatomaceous earth, 5 parts of bentonite, 2 parts of hydroxyethyl cellulose,

[0068]The raw material composition and ratio of component B are:

[0069] 10 parts of urea, 15 parts of ammonium dihydrogen phosphate, 1 part of carboxymethyl starch, 1 part of biological nitrogen-fixing bacteria, 0.1 part of N-butylthiophosphoric diamide (BTPT), 0.1 part of dicyandiamide,

[0070] The raw material composition and ratio of component C are: 0.8 parts of polyaspartic acid, 2 parts of polyvinylpyrrolidone, and 2 parts of casein.

[0071]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com