Corrosion-inhibition scale inhibitor composition and corrosion-inhibition scale inhibitor and application thereof

A technology of corrosion and scale inhibitors and compositions, which is applied in the field of corrosion and scale inhibitors and corrosion and scale inhibitor compositions, can solve the problems of limited treatment effect, high labor intensity, and large alkali consumption, and achieve good mitigation Corrosion performance and scale inhibition performance, improvement of corrosion inhibition performance, and the effect of inhibiting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

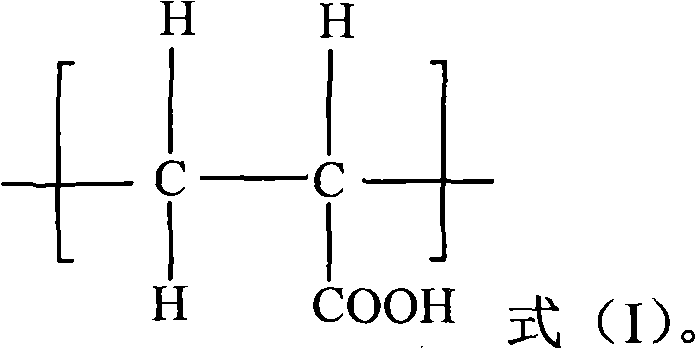

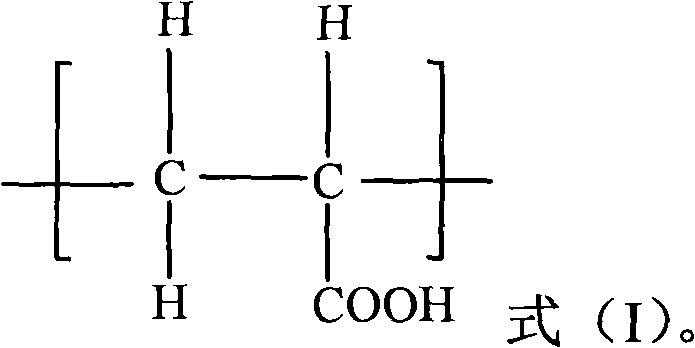

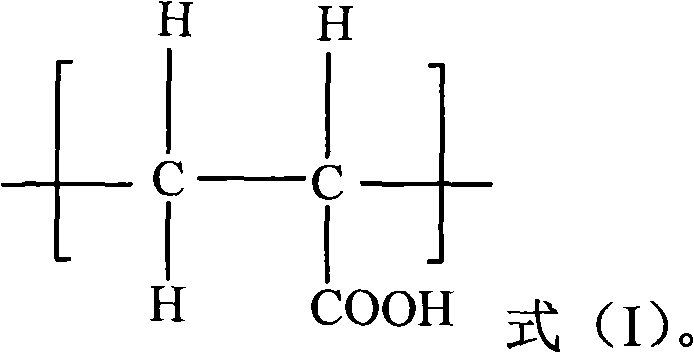

Method used

Image

Examples

Embodiment 1-7

[0074] This example is used to illustrate the corrosion and scale inhibitor provided by the present invention and its preparation method.

[0075] Various raw materials in the corrosion and scale inhibitor compositions of Examples 1-7 and the conditions for mixing the corrosion and scale inhibitor compositions with water are shown in Table 2, wherein polyepoxysuccinic acid, hydrolyzed polymaleic anhydride, acrylic acid Copolymer with 2-acrylamido-2-methyl-propanesulfonic acid, Copolymer of acrylic acid with 2-acrylamido-2-methyl-propanesulfonic acid and maleic anhydride, Acrylic acid with methyl acrylate and acrylate hydroxy Propyl ester copolymers were purchased from Beijing Linhua Water Quality Stabilizer Factory, and the trade numbers were RP-112, BC-500, RP-35, RP-33, and BC-508.

[0076] Table 2

[0077]

experiment Embodiment 1-9

[0079] This experimental example is used to illustrate the corrosion and scale inhibition performance test of the corrosion and scale inhibitors.

[0080] With reference to the GB / T 18175-2000 standard "Measurement of Corrosion Inhibition Performance of Water Treatment Agents by Rotary Coupon Method", the corrosion and scale inhibitors obtained in Examples 1-7 of the present invention and blank sample A are disclosed in Example 2 of CN101805067A The composite corrosion inhibitor B carried out the rotary coupon corrosion test, and with reference to the GB / T 16632-2008 standard "Measuring Calcium Carbonate Deposition Method for Scale Inhibition Performance of Water Treatment Agents", the corrosion inhibitors obtained in Examples 1-7 of the present invention Scale inhibitor, blank sample A and composite corrosion inhibitor B disclosed in Example 2 of CN101805067A were subjected to calcium carbonate scale inhibition test.

[0081] Test water quality: Calcium hard (as CaCO 3 Calcula...

experiment Embodiment 10

[0087] The corrosion and scale inhibitor obtained in Example 1 of the present invention is carried out laboratory dynamic simulation test (with reference to the chemical industry standard HG / T 2160-2008 "cooling water dynamic simulation test method"), using the same method as in Experimental Examples 1-9 water quality as supplementary water. The mass concentration of corrosion and scale inhibitors in water is controlled at 90-110mg / L.

[0088] 2 pieces of Φ10×1×500mm 20 # The carbon steel test tubes were tested in parallel, and the test water added with the corrosion and scale inhibitor of the present invention went through the tubes. The test tube is externally heated with saturated steam, the temperature of the experimental water inlet is controlled at 30±1°C, the temperature difference between the inlet and outlet is 10°C, the flow rate is 0.8-1m / s, and the total phosphorus (as PO 4 3- meter) mass concentration is 8mg / L, the concentration multiple of circulating water (b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com