Light transmission body

一种光传输体、被覆层的技术,应用在内窥镜领域,能够解决光纤端面成型性和研磨精度变差、粘接性降低、无法达到观察性能等问题,达到优异耐久性、充分粘接性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] The optical transmission body of the embodiment was manufactured, and the durability and the state of polishing were evaluated.

[0040]

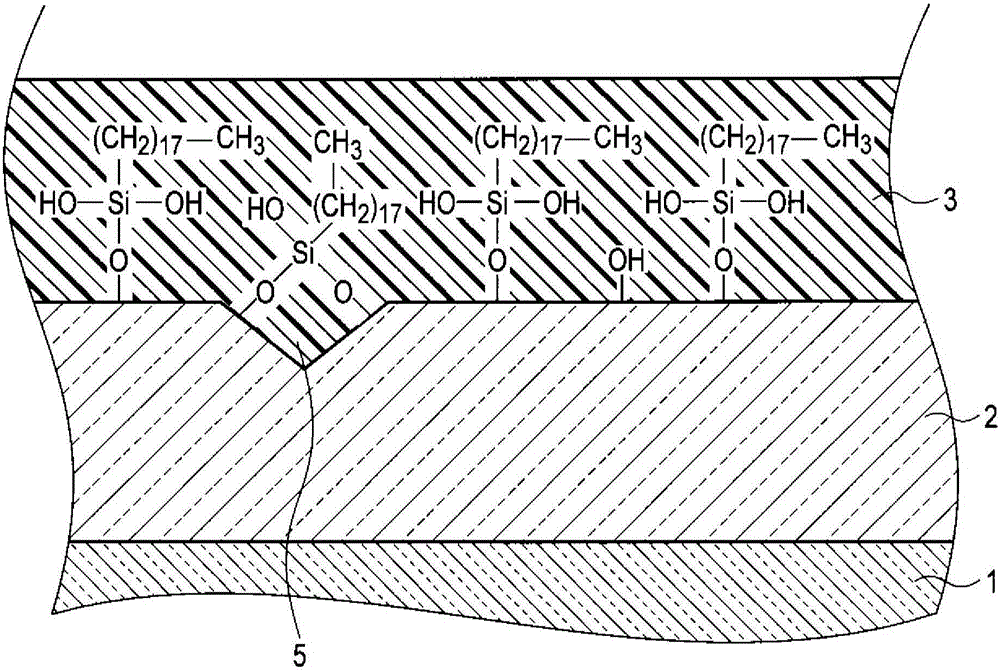

[0041] Add 0.01% to 20% of alkylsilane (general formula CH 3 (CH 2 ) m Si(OR) n (R') 3-n ) and 0-20% of the dispersant are dissolved in water to prepare a treatment liquid. However, the total of the alkylsilane and the dispersant is 30% or less. In addition, the concrete compound name of an alkylsilane and a dispersing agent is as described in Table 1 mentioned later. As a dispersant, an organic solvent or a surfactant is used. Thus, 14 kinds of treatment liquids (Examples 1 to 14) were obtained.

[0042] In addition, as a comparison, a treatment liquid in which an organosilicon compound containing a fluorine-substituted alkyl group was used instead of an alkylsilane at 0.01% to 10% was produced (comparative example 1).

[0043]

[0044] The fiber strands were immersed in each of the 15 kinds of treatment liquids produced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com