Binder composition, electrode mixture, electrode, and non-aqueous electrolyte secondary battery

A technology of composition and adhesive, applied in the direction of non-aqueous electrolyte battery, non-aqueous electrolyte battery electrode, non-aqueous electrolyte, etc., can solve the problem of weak adhesion of metal foil and achieve the effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

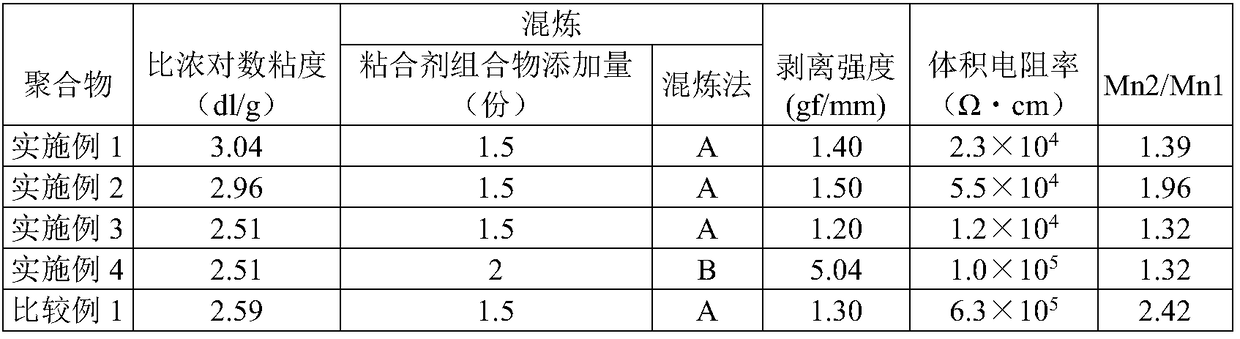

Examples

Embodiment 1

[0102] [Preparation of Adhesive Composition]

[0103] In an autoclave with an inner capacity of 2 liters, 930 g of ion-exchanged water as a dispersion medium, 0.2 g of Metolose SM-100 (manufactured by Shin-Etsu Chemical Co., Ltd.) as a cellulose-based suspending agent, and 50 wt. 3.2 g of tert-diisopropyl peroxydicarbonate-Freon 225cb solution, 400 g of vinylidene fluoride, and 0.2 g of acrylic acid as a monomer were heated to 26° C. over 1 hour. Next, while maintaining 26 degreeC, 98 g of 2 wt% acrylic acid aqueous solutions were added over 9 hours. The polymerization was terminated when 25.7 hours had elapsed from the temperature rise.

[0104] After the polymerization was completed, the polymer slurry was heat-treated at 95°C for 60 minutes, dehydrated, washed with water, and dried at 80°C for 20 hours, thereby obtaining an adhesive composition (vinylidene fluoride copolymer) combination). The yield of the polymkeric substance obtained is 96%, inherent viscosity η i 3.0...

Embodiment 2

[0111] [Preparation of Adhesive Composition]

[0112] In an autoclave with an inner capacity of 2 liters, 900 g of ion-exchanged water as a dispersion medium, 0.4 g of Metolose 90SH-100 (manufactured by Shin-Etsu Chemical Co., Ltd.) as a cellulose-based suspending agent, and 50 wt. 3.0 g of tert-butyl peroxypivalate-freon 225cb solution, 400 g of vinylidene fluoride, and 0.2 g of acrylic acid as a monomer were heated up to 50° C. over 2 hours. Next, while maintaining 50° C., a 0.3 wt % acrylic acid aqueous solution was slowly added at a constant rate of polymerization pressure. Acrylic acid was added in a total amount of 2.0 g including the initially added amount. Simultaneously with the completion of the addition of the aqueous acrylic acid solution, the polymerization was stopped. The total time from the start of temperature rise to the stop of polymerization was 9.8 hours.

[0113] After completion of the polymerization, the polymer slurry was heat-treated at 95° C. for ...

Embodiment 3

[0119] [Preparation of Adhesive Composition]

[0120]In an autoclave with an inner capacity of 2 liters, 900 g of ion-exchanged water as a dispersion medium, 0.4 g of Metolose 90SH-100 (manufactured by Shin-Etsu Chemical Co., Ltd.) as a cellulose-based suspending agent, and 50 wt. 4.0 g of tert-butyl peroxypivalate-freon 225cb solution, 400 g of vinylidene fluoride, and 0.2 g of acrylic acid as a monomer were heated up to 50° C. over 2 hours. Next, while maintaining 50° C., a 0.3 wt % acrylic acid aqueous solution was slowly added at a constant rate of polymerization pressure. Acrylic acid was added in a total amount of 2.0 g including the initially added amount. Simultaneously with the completion of the addition of the aqueous acrylic acid solution, the polymerization was stopped. The total time from the start of temperature rise to the stop of polymerization was 9.4 hours.

[0121] After completion of the polymerization, the polymer slurry was heat-treated at 95° C. for 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| logarithmic viscosity | aaaaa | aaaaa |

| logarithmic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com