Adhesive sheet

An adhesive sheet, adhesive force technology, applied in the direction of adhesives, film/sheet adhesives, electrical components, etc., can solve the problem of difficult to take into account the handleability, and achieve the effect of improving productivity and excellent handleability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

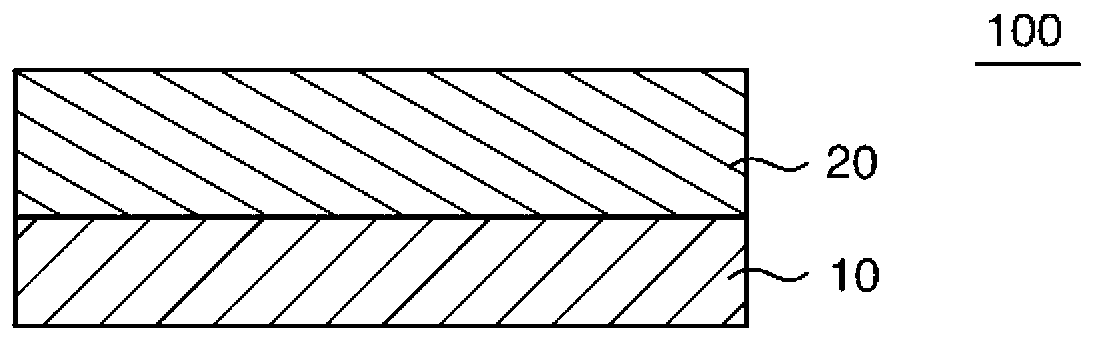

Image

Examples

Embodiment 1

[0066] An ethylene-vinyl acetate copolymer (manufactured by DU PONT-MISUI CO., LTD., trade name "EVAFLEXP-1007") was used as a material for forming the base material layer.

[0067] Using an amorphous propylene-(1-butene) copolymer polymerized by a metallocene catalyst (manufactured by Sumitomo Chemical Co., Ltd., trade name "TAFTHREN H5002"): structural unit derived from propylene 90 mol% / derived from 1-butane 10 mol % of structural units of alkene, Mw=230000, Mw / Mn=1.8) as a material for forming the adhesive layer.

[0068] 100 parts of the above-mentioned material forming the substrate layer and 100 parts of the above-mentioned material forming the adhesive layer are put into respective extruders, and carry out T-die melt co-extrusion (extruder:

[0069] GM ENGINEERING, Inc., trade name "GM30-28" / T-die: clamp-type feeding mechanism, extrusion temperature: 180°C). The melted resin co-extruded from the die and the Si-coated PET separator (manufactured by Mitsubishi Chemica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com