Pressure-sensitive adhesive sheet for conveying electrolyte membrane and method using said pressure-sensitive adhesive sheet to manufacture fuel-cell membrane electrode assembly

An electrolyte membrane, manufacturing method technology, used in fuel cells, film/sheet adhesives, final product manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

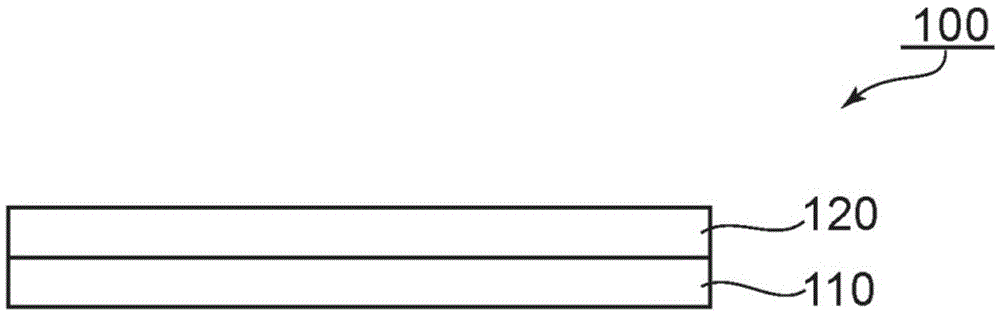

[0140] Figure 4 It is a figure for demonstrating the outline|summary of the manufacturing method of the fuel cell membrane / electrode assembly based on 1st Embodiment of this invention. In this first embodiment, a membrane / electrode complex 300 including the first gas diffusion electrode 20 , the polymer electrolyte membrane 10 and the second gas diffusion electrode 30 can be produced.

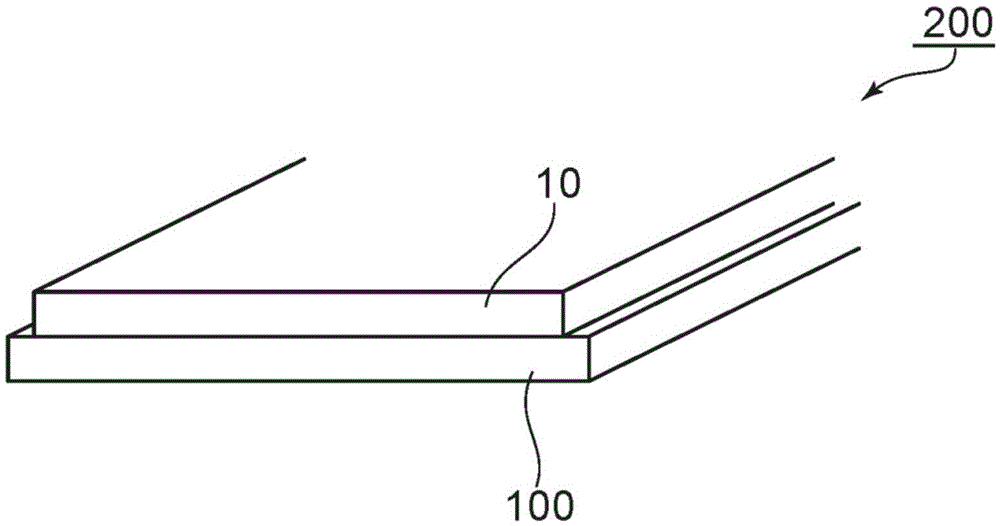

[0141] Preferably, as the first step, the laminate described in item E including the above-mentioned adhesive sheet 100 for transporting electrolyte membranes and the polymer electrolyte membrane 10 on the adhesive sheet 100 is prepared in the form of a roll, and discharged from the roll. The stack.

[0142] Next, as a second step, the first gas diffusion electrode 20 is laminated on the surface of the polymer electrolyte membrane 10 opposite to the pressure-sensitive adhesive sheet 100 . The gas diffusion electrode used in the present invention is not particularly limited, and any appropria...

no. 2 Embodiment approach

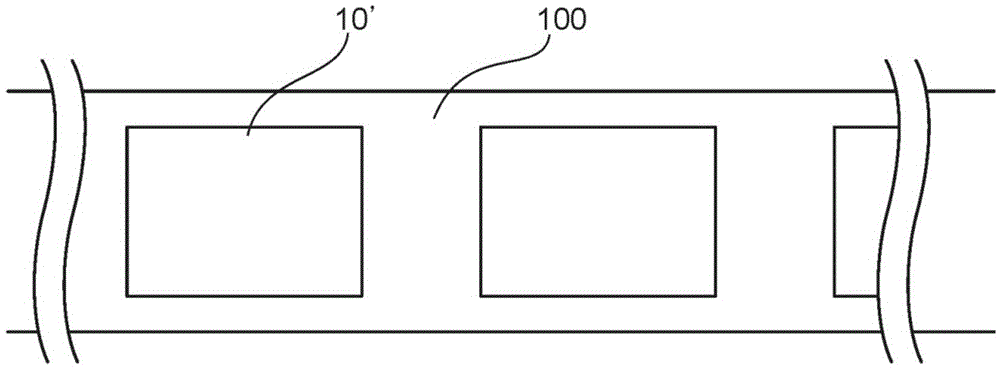

[0153] Figure 5 It is a figure for demonstrating the outline of the manufacturing method of the fuel cell membrane / electrode assembly based on the 2nd Embodiment of this invention. In the second embodiment, a membrane / electrode complex including the first gas diffusion electrode 20', the polymer electrolyte membrane 10, and the second gas diffusion electrode in this order can be manufactured. In the second embodiment, the first gas diffusion electrode 20' includes a catalyst layer 21 and a gas diffusion layer 22 in this order from the polymer electrolyte membrane 10 side. In addition, the second gas diffusion electrode may include a catalyst layer and a gas diffusion layer. It should be noted that, in Figure 5 In the drawing, the process up to the formation of the first gas diffusion electrode 20' in the manufacturing method of the fuel cell membrane / electrode assembly is shown.

[0154] Also in this embodiment, as the first step, the laminate described in item E includin...

Embodiment 1

[0173] (Preparation of material for adhesive layer formation)

[0174] Put methacrylic acid into the experimental apparatus for polymerization equipped with a 1L round-bottom detachable flask, detachable hood, separatory funnel, thermometer, nitrogen gas introduction tube, Liebig condenser, vacuum seal, stirring rod, and stirring blades 100 parts by weight of lauryl ester (manufactured by Kao Corporation, trade name "EXCEPARLL-MA"), 10.2 parts by weight of 2-hydroxyethyl methacrylate (manufactured by Mitsubishi Rayon Corporation, trade name "ACRYESTERHO"), As a polymerization initiator, 0.22 parts by weight of 2,2'-azobisisobutyronitrile (manufactured by Kishida Chemical Co., Ltd.) and 55 parts by weight of toluene were used to prepare a mixture.

[0175] While stirring the mixture, the inside of the round-bottomed separable flask was replaced with nitrogen at normal temperature. Then, the mixture was stirred at a temperature of 60° C.±2° C. for 12 hours while flowing nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com