Wafer working tape

A wafer processing and adhesive technology, applied in the direction of film/sheet adhesive, adhesive type, electric solid device, etc., can solve the problem that the adhesive layer cannot be peeled off, and the adhesive layer is in contact with the adhesive layer Long time and other problems, to achieve the effect of full adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

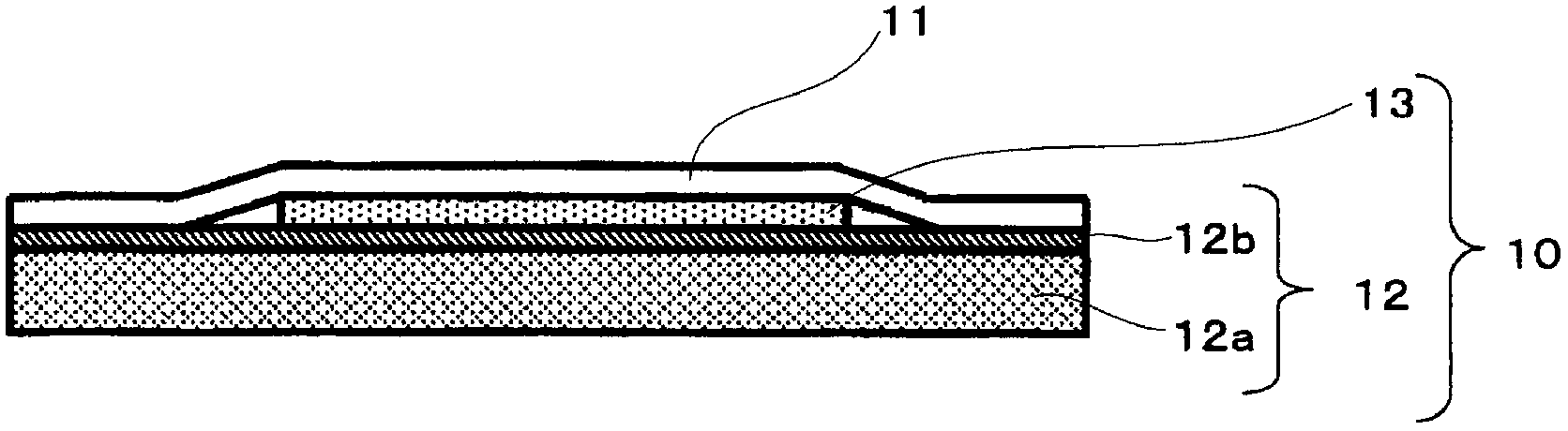

[0102] The adhesive layer (1) obtained above and the adhesive film (1) were bonded so that only one side of the PET film of the adhesive layer was peeled off, and the adhesive layer was in contact with the adhesive layer, and the supporting base material, the adhesive layer, and the Mixture layer, adhesive layer, anti-adhesive film, get figure 1 Wafer processing tape with release film shown. This wafer processing tape was used as a sample of Example 1.

Embodiment 2

[0104] The tape for wafer processing of Example 2 was produced by the method similar to Example 1 using the obtained said adhesive bond layer (2) and adhesive film (1).

Embodiment 3

[0106] The tape for wafer processing of Example 3 was produced by the method similar to Example 1 using the obtained said adhesive bond layer (3) and adhesive film (1).

PUM

| Property | Measurement | Unit |

|---|---|---|

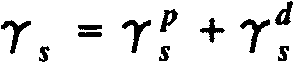

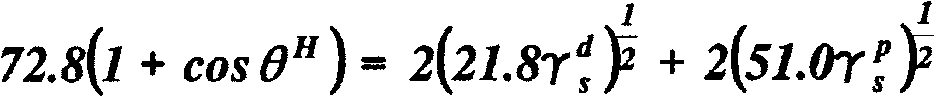

| surface free energy | aaaaa | aaaaa |

| surface free energy | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com