Pressure-sensitive adhesive tape

A technology of adhesive tape and adhesive layer, applied in the direction of adhesive, film/sheet adhesive, adhesive products, etc., can solve the problems of difficult prism sheet appearance inspection, etc., and achieve the effect of suppressing fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

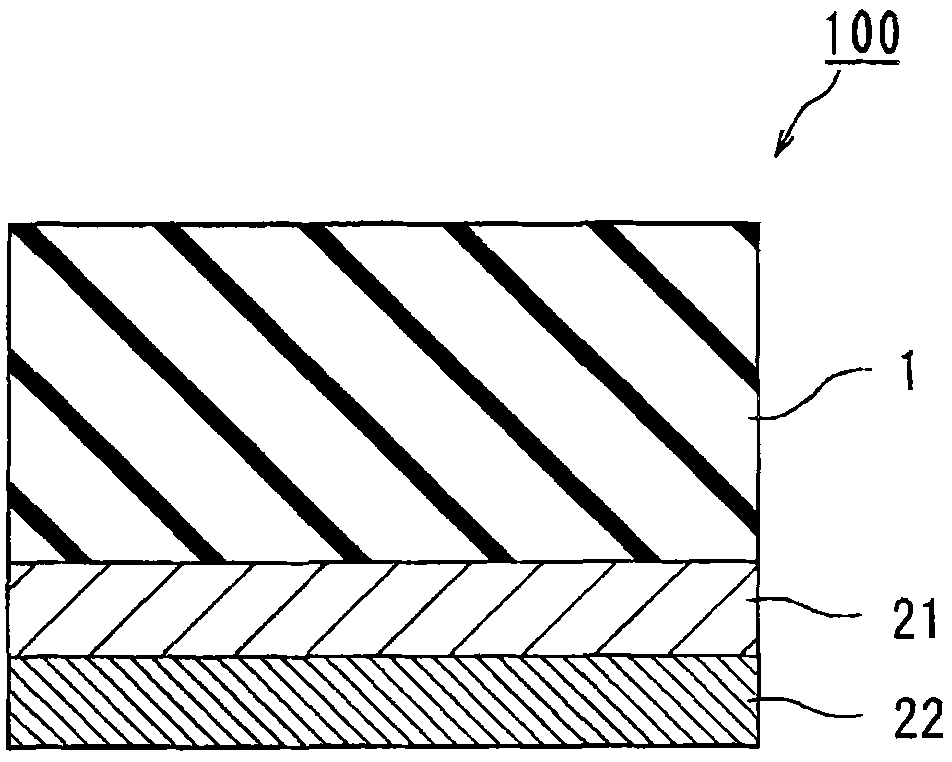

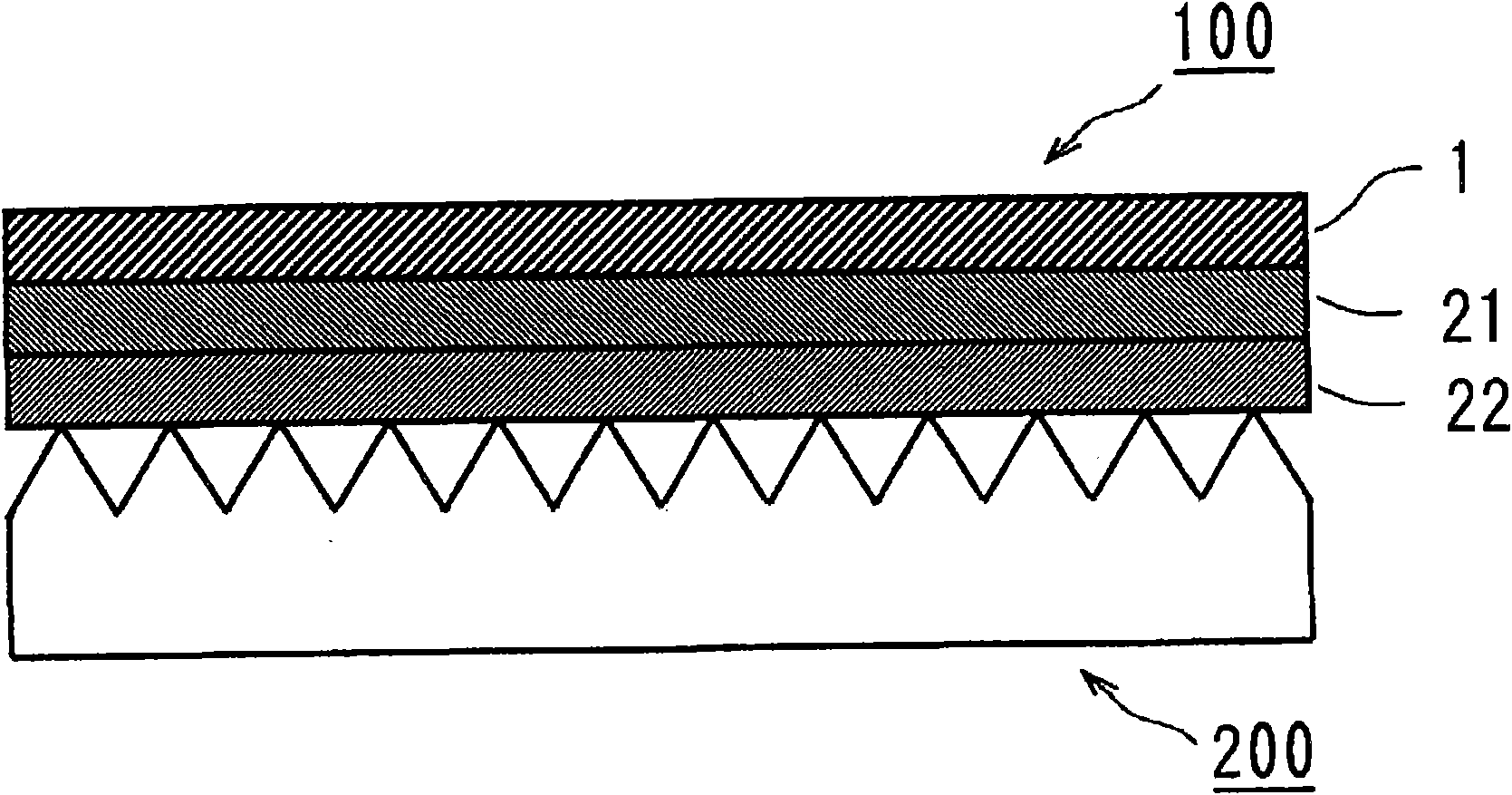

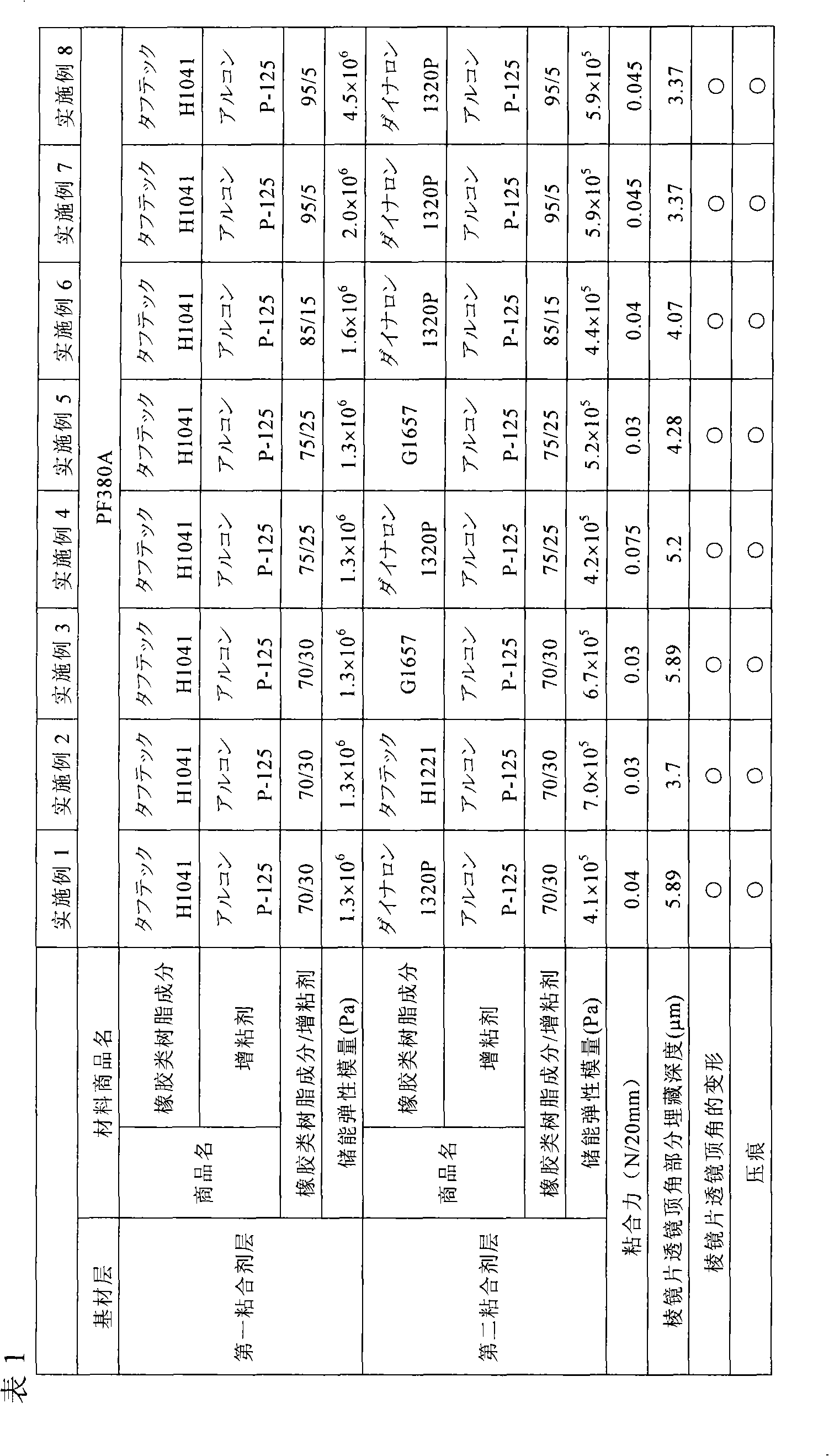

[0105] The following compounds were prepared as the substrate layer forming material, the first pressure-sensitive adhesive layer forming material, and the second pressure-sensitive adhesive layer forming material.

[0106] Substrate layer forming material: Block polypropylene (manufactured by SunAllomer: PF380A)

[0107] Material for forming the first adhesive layer: 70 parts of a styrene-based elastomer (manufactured by Asahi Kasei Chemical Co., Ltd.: タフテック H1041) composed of a hydrogenated product of a styrene-butadiene-based copolymer, and a tackifier (manufactured by Arakawa Chemical Industry Co., Ltd.) : Alcon P-125) 30 parts mixture

[0108] Material for forming the second adhesive layer: 70 parts of styrene-based elastomer (manufactured by JSR Corporation: Dinaron 1320P) composed of a hydrogenated product of a styrene-butadiene-based copolymer and a tackifier (manufactured by Arakawa Chemical Industry Co., Ltd.: Alcon P-125) 30 parts mixture

[0109] The above materi...

Embodiment 2

[0111] 70 parts of a styrene-based elastomer (manufactured by Asahi Kasei Chemical Co., Ltd.: テフテック H1041) and 30 parts of a tackifier (manufactured by Arakawa Chemical Industry Co., Ltd.: Alcon P-125) composed of hydrogenated styrene-butadiene copolymers were used. As a material for forming the first adhesive layer, 70 parts of a styrene-based elastomer (manufactured by Asahi Kasei Chemical Co., Ltd.: タフテック H1221) composed of a hydrogenated styrene-butadiene copolymer and a tackifier (Arakawa Chemical industry company make: Alcon P-125) 30 parts of mixtures were used as a 2nd adhesive layer forming material, and it carried out similarly to Example 1, and obtained the adhesive tape (2). The thickness of the substrate layer was 38 μm, the thickness of the first adhesive layer was 4 μm, and the thickness of the second adhesive layer was 4 μm. Table 1 shows the evaluation results of the obtained adhesive tape (2).

Embodiment 3

[0113] 70 parts of a styrene-based elastomer (manufactured by Asahi Kasei Chemical Co., Ltd.: テフテック H1041) and 30 parts of a tackifier (manufactured by Arakawa Chemical Industry Co., Ltd.: Alcon P-125) composed of hydrogenated styrene-butadiene copolymers were used. As a material for forming the first adhesive layer, 70 parts of a styrene-based elastomer (manufactured by Kraton: G1657) composed of a hydrogenated styrene-butadiene copolymer and a tackifier (Arakawa Chemical Co., Ltd. Industrial Co., Ltd. product: Alcon P-125) Except having used the mixture of 30 parts as a 2nd adhesive layer forming material, it carried out similarly to Example 1, and obtained the adhesive tape (3). The thickness of the substrate layer was 38 μm, the thickness of the first adhesive layer was 4 μm, and the thickness of the second adhesive layer was 4 μm. Table 1 shows the evaluation results of the obtained adhesive tape (3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com