Method for forming electroconductive pattern, and electroconductive pattern substrate

A conductive pattern and substrate technology, which can be applied to equipment for manufacturing conductive/semiconductive layers, components of conductive cores, lithography/patterns, etc. Large burden and other problems, to achieve the effect of sufficient adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

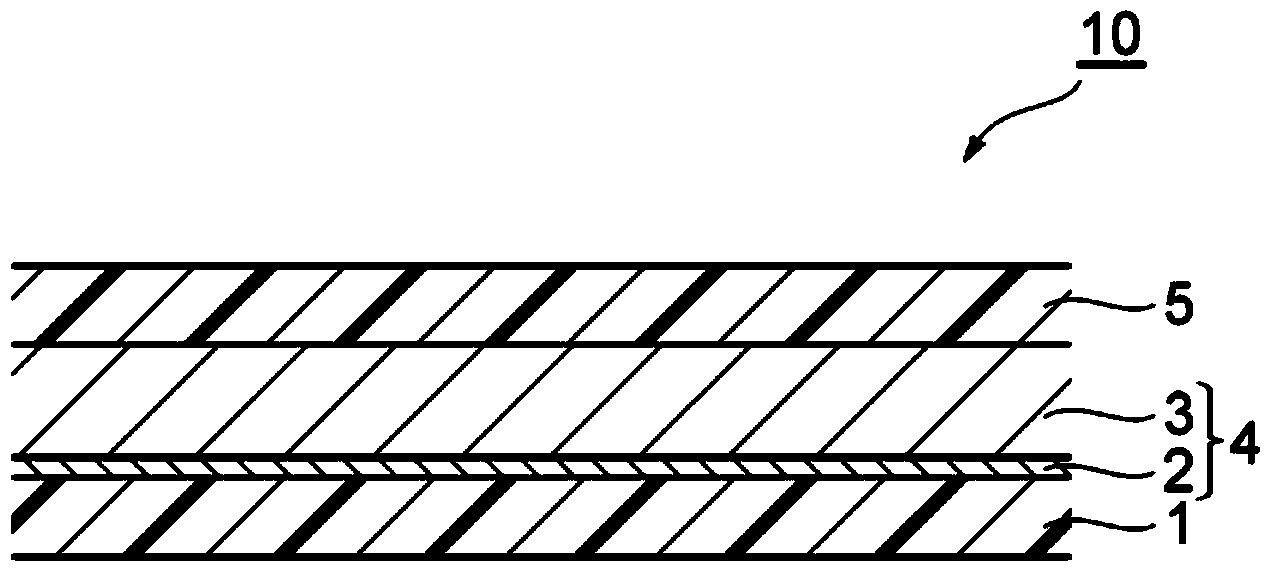

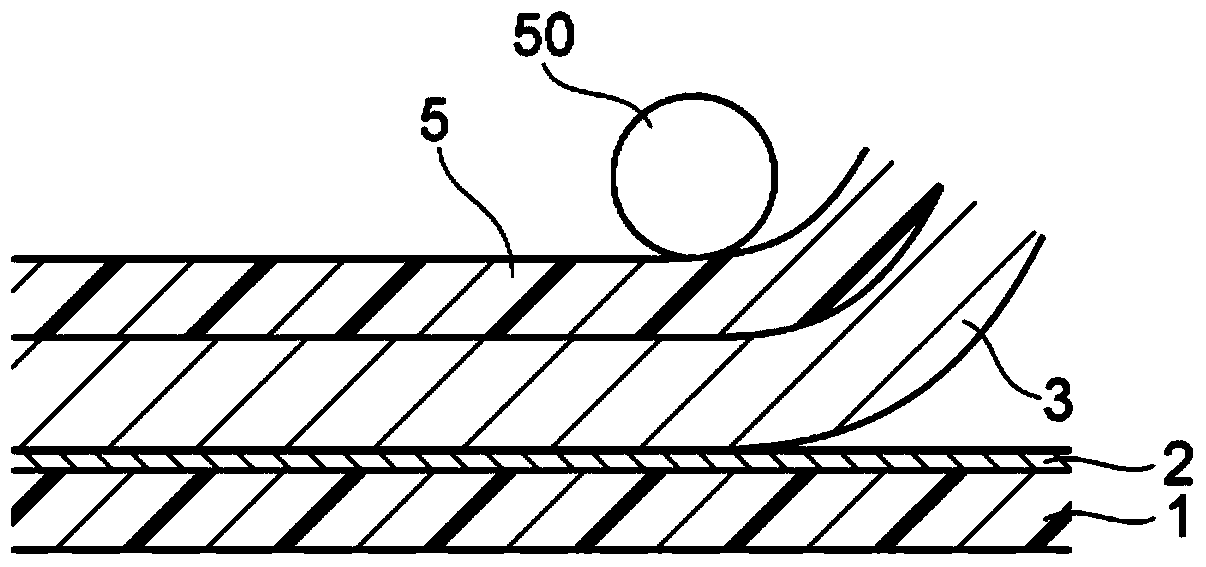

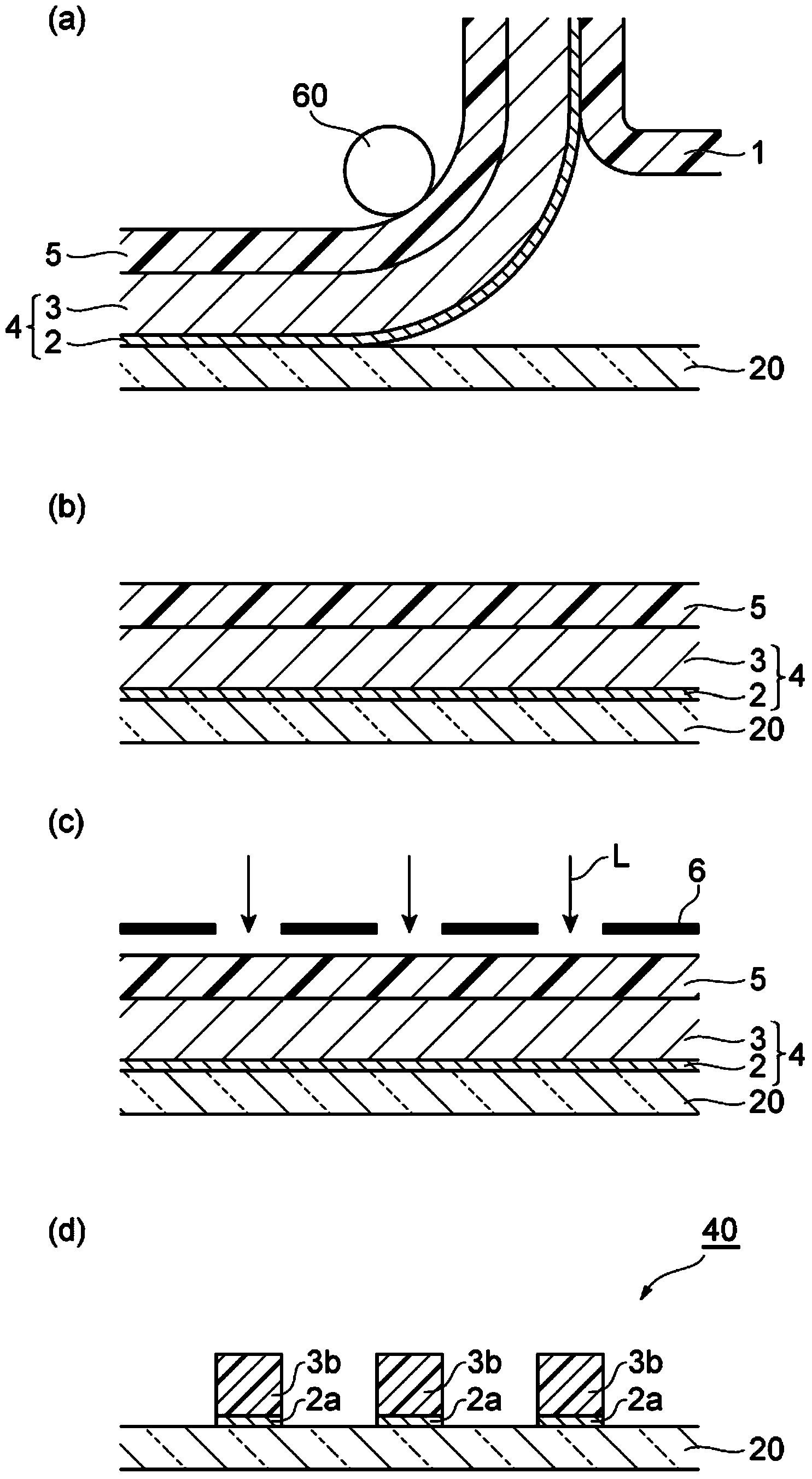

Method used

Image

Examples

Embodiment 1

[0150] On a polyethylene terephthalate film (PET film, manufactured by Teijin Co., Ltd., trade name: G2-16) with a thickness of 16 μm as a support film, the 2 Uniformly apply the above-mentioned conductive fiber dispersion liquid 1, dry it with a hot air convection dryer at 100°C for 10 minutes, and pressurize it with a linear pressure of 1 MPa at room temperature (25°C), thereby forming a layer containing conductive fibers on the support film. The conductive layer of the fiber. In addition, the film thickness after drying of the conductive layer was about 0.1 micrometer as a result of the measurement by the scanning electron micrograph.

[0151] Next, the solution of the above-mentioned photosensitive resin composition was evenly coated on a polyethylene terephthalate film (PET film, manufactured by Teijin Co., Ltd., trade name: G2-50) with a thickness of 50 μm prepared separately, It dried for 10 minutes with the hot-air convection type dryer of 100 degreeC, and formed the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com