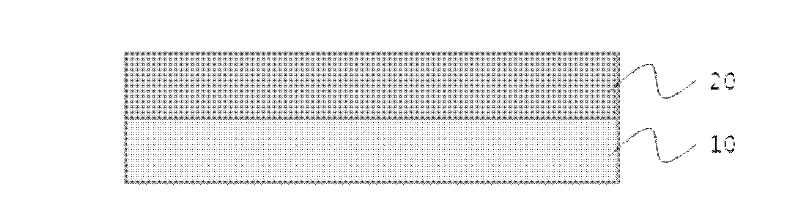

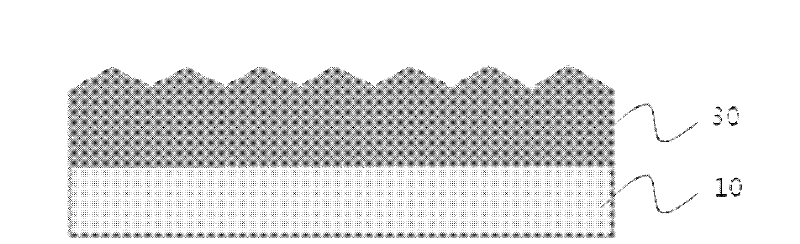

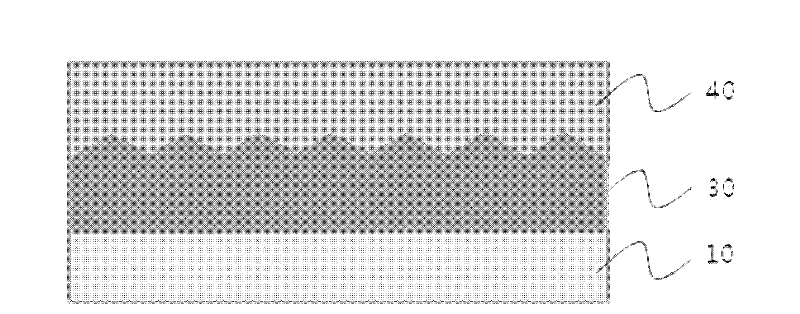

Method for manufacturing thick polyimide flexible metal-clad laminate

A technology of metal-clad laminates and polyimide layers is applied in the field of preparation of polyimide thick-film flexible metal-clad laminates, which can solve the problems of difficulty in preparation, foaming and the like, and achieve the effect of low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0069] In a nitrogen atmosphere, 12,312 g of diamine-based PDA and 2,533 g of ODA were added and stirred to 211,378 g of DMAc solution, and after complete dissolution, 38,000 g of BPDA as an acid anhydride was added in portions. After that, the stirring was continued for about 24 hours to prepare a polyamic acid solution. The prepared polyamic acid solution was cast into a film with a thickness of 20 μm, the temperature was raised to 350° C. for 60 minutes, and then kept for 30 minutes to harden. The measured coefficient of linear thermal expansion was 13.0 ppm / K.

Synthetic example 2

[0071] In a nitrogen atmosphere, 3,063 g of diamine-based PDA and 2,431 g of ODA were added to 117,072 g of DMAc solution, stirred, and after complete dissolution, 12,000 g of BPDA as an acid anhydride was added in portions. After that, the stirring was continued for about 24 hours to prepare a polyamic acid solution. The prepared polyamic acid solution was cast into a film with a thickness of 20 μm, the temperature was raised to 350° C. for 60 minutes, and then kept for 30 minutes to harden. The measured linear coefficient of thermal expansion was 25.1 ppm / K.

Synthetic example 3

[0073] In a nitrogen atmosphere, 948 g of diamine-based BAPB was added to 11,572 g of DMAc solution, stirred, and 757 g of bisanhydride BPDA was added after completely dissolving. After that, the stirring was continued for about 24 hours to prepare a polyamic acid solution. The thus-prepared polyamic acid solution was cast into a film with a thickness of 20 μm, the temperature was raised to 350° C. for 60 minutes, and then kept for 30 minutes to harden. The measured coefficient of linear thermal expansion was 65.1 ppm / K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com